Container with a bevelled edge and an adjacent transverse curved edge

A container and edge technology, applied in the field of blanks forming the container, can solve the problems of container structure damage, container visual and tactile perception effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

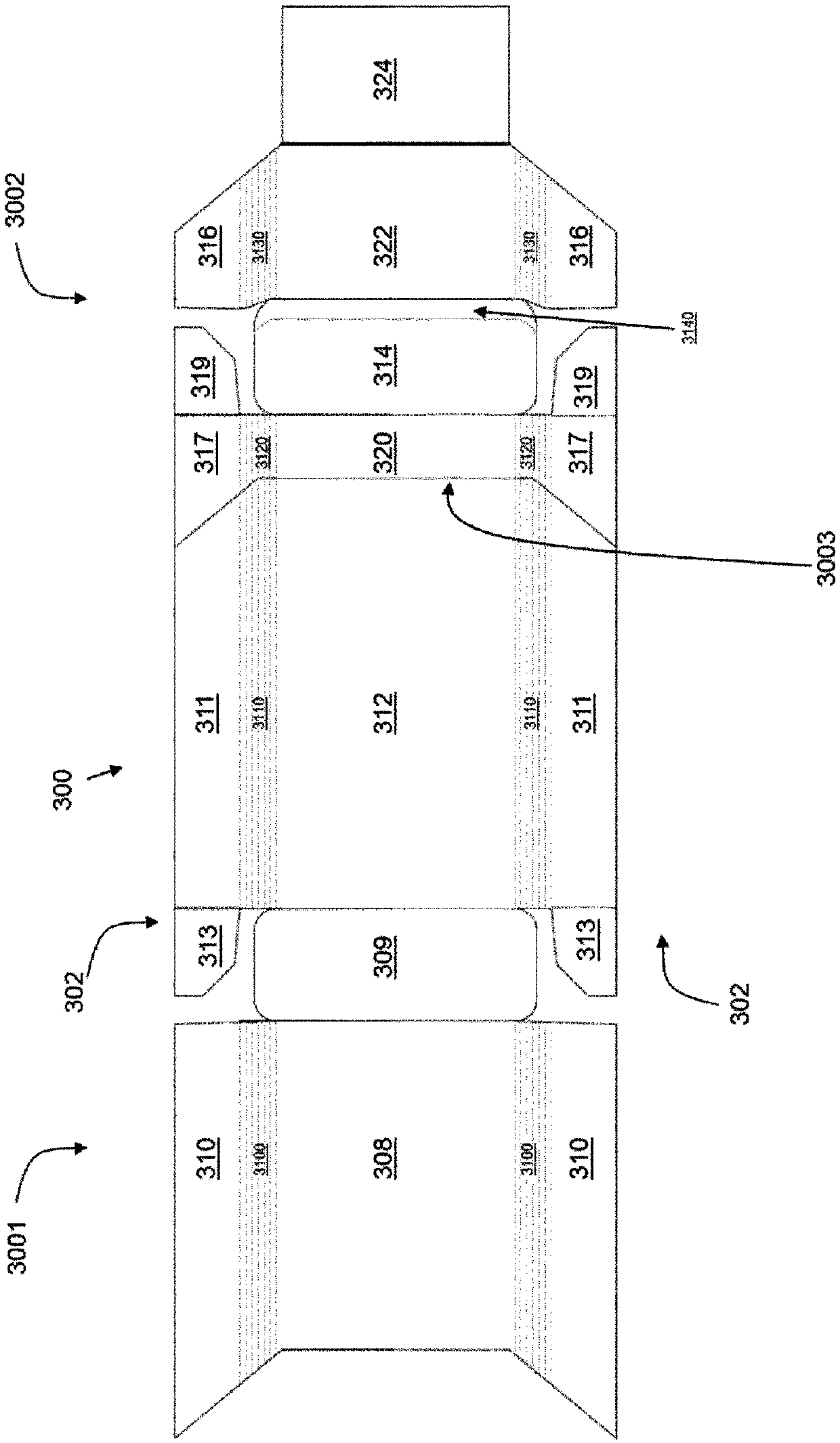

[0088] image 3 is a view of a cardboard blank 300 for forming a container for consumer goods according to the present invention.

[0089] The blank 300 comprises a box blank portion 3001 for forming the box portion of the container and a lid blank portion 3002 for forming the lid portion of the container. The box blank portion 3001 depends from the lid blank portion 3002 along a hinge line 3003 .

[0090] The box blank portion 3001 includes a front wall panel 308 , a rear wall panel 312 and a bottom wall panel 309 . Two side wall panels 310 extend from the front wall panel 308 , two side wall panels 311 extend from the rear wall panel 312 , and two box dust flaps 313 extend from the side wall panels 311 . When the box portion of the container is assembled from the box blank portion 3001, the front wall panel 308 forms the container front wall, the rear wall panel 312 forms the container rear wall, the side wall panels 310, 311 overlap to form the left and right side contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com