A description method of disintegration characteristics based on field state of soft rock

A disintegration and on-site technology, applied in special data processing applications, design optimization/simulation, etc., can solve the problems of in-situ argillaceous rock disintegration, disintegration flow loss, and difficult scientific and reasonable characterization of soft rock mass disintegration Solving problems such as features to achieve the effect of enriching evaluation index information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Description of the Results of the Confined Disintegration Test with Non-fixed Volume

[0050] The undisturbed samples of argillaceous sandstone and mudstone are all taken from the K42+040 pilot project of diverting the Yangtze River to the Huaihe River, in the middle of the channel, at a depth of 12-13m. Determination of the secondary cycle disintegration resistance index I of the rock by the standardized disintegration resistance test method d2 Both are less than 2.5%, which means strong disintegration, and the difference cannot be distinguished. On this basis, this experiment is to study the influence of confinement on the results of disintegration test.

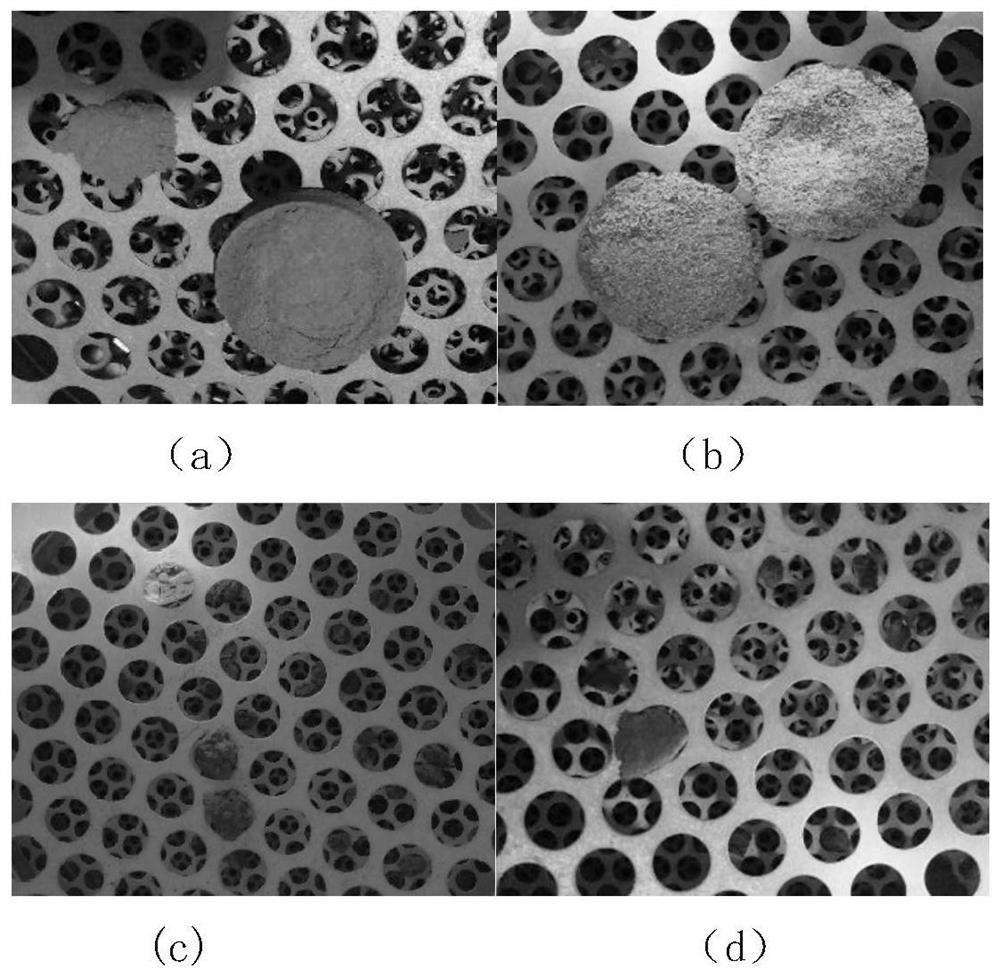

[0051] Such as figure 1 Shown:

[0052] (1) Sieving of disintegrated matter.

[0053] The test results of two groups of argillaceous sandstone and mudstone samples. Such as figure 1 As shown, the sieving results can significantly distinguish the disintegration characteristics of argillaceous sandsto...

Embodiment 2

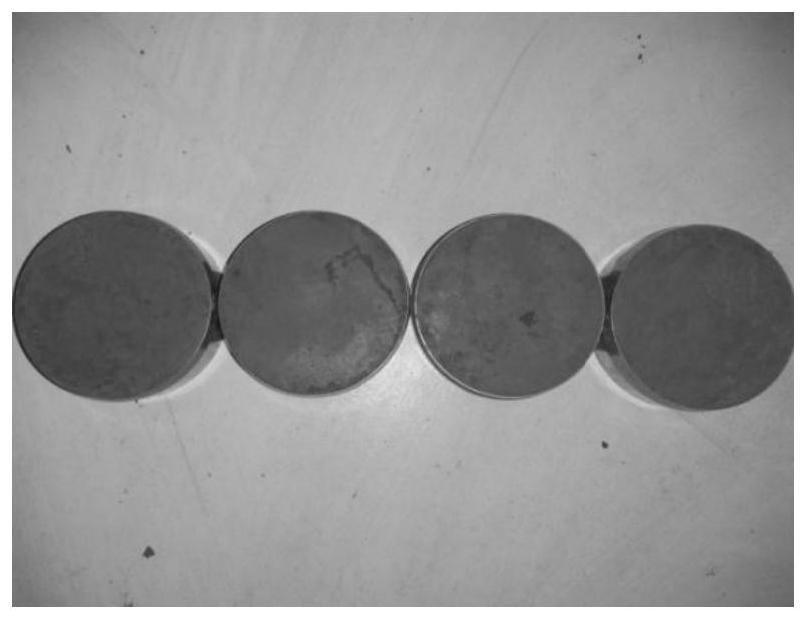

[0078] Example 2: Description of the results of the confining disintegration test at a fixed volume under dry-wet cycle conditions

[0079] Since the sample has a low diagenetic degree and is a weakly cemented argillaceous very soft rock with some characteristics of rock and soil, the original sample of the ring cutter can be prepared according to the preparation method of the original geotechnical sample, such as image 3 shown. The confinement is realized by the ring knife, and the saturator is used to fix the ring knife sample when immersed in water, such as Figure 4 . The surface information of the rock sample is collected by using a camera and a crack width measuring instrument to measure the crack width on the rock sample surface. When taking pictures, in order to ensure that the distance, location, and external light environment of each shot are consistent, the camera is placed at a height of about 5cm in the center of the ring knife-like surface to shoot, and all sh...

Embodiment 3

[0087] Embodiment 3: Description of research results of static disintegration test of rock block

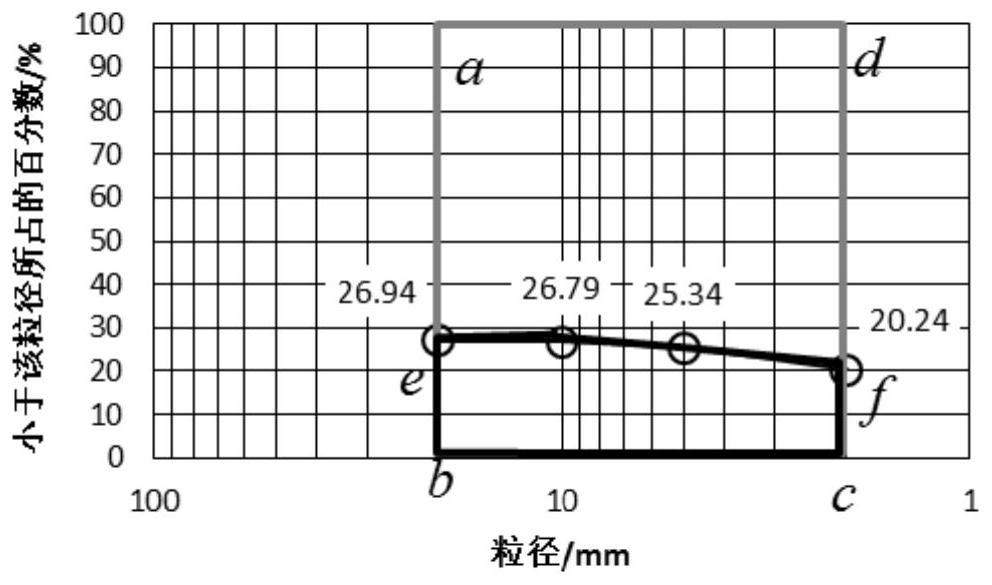

[0088] Drying quality of mudstone initial rock sample block D 0 =260.10g; drying quality of the initial rock sample block of argillaceous sandstone D 0 = 245.00 g. Starts to disintegrate after immersion in water. Particle analysis of the disintegrated product was performed after the disintegration was completed.

[0089] A. Determination method: Pass the sample through standard sieves with apertures of 60mm, 40mm, 20mm, 10mm, 5mm, 2mm, 1mm, 0.5mm, and 0.075mm, sieve and weigh, and obtain the disintegration samples that pass through different standard sieve apertures. The dry weight of the material is shown in Table 4 and Table 5. The particle distribution characteristic curve is obtained, such as Image 6 , Figure 7 . According to the particle distribution characteristic curve, determine the critical particle size d 60 , that is, particles smaller than this particle size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com