A device for testing tensile strength

A test device and tensile strength technology, applied in the field of tensile strength test devices, can solve the problems of high cost, lack of special equipment, slow response of test results, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

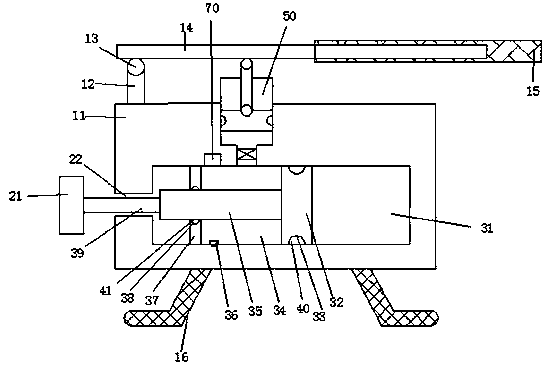

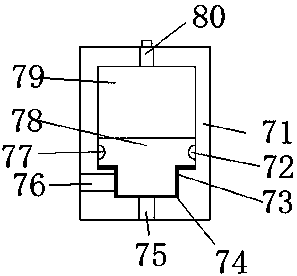

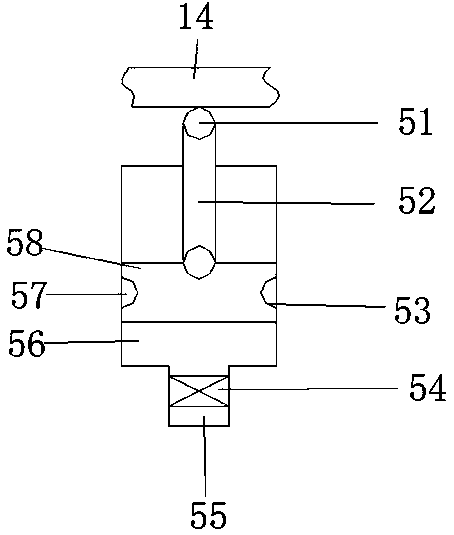

[0014] like figure 1 , figure 2 and image 3 As shown in the figure, a tensile strength testing device of the present invention includes a frame body 11, a stretching device installed inside the frame body 11, and a gas injection device installed at the upper end of the frame body 11. The stretching device includes a first air cavity 31 arranged on the right side of the stretching device, and a first movable block 32 is disposed on the left side of the first air cavity 31, and the first movable block 32 is connected to the first air cavity. 31 sliding connection and fit, the first movable block 32 is provided with a first sealing recess 33 on the peripheral side, and a first sealing ring 40 is provided in the first sealing recess 33, and the first sealing ring 40 ensures the For the air tightness of the first air cavity 31, a first movable rod 35 is provided on the left side of the first movable block 32, and the right side of the first movable rod 35 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com