Demoulding structure

A technology of demolding and master mold, applied in the field of mold release structure, can solve problems such as sticking master mold, and achieve the effect of solving sticking master mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

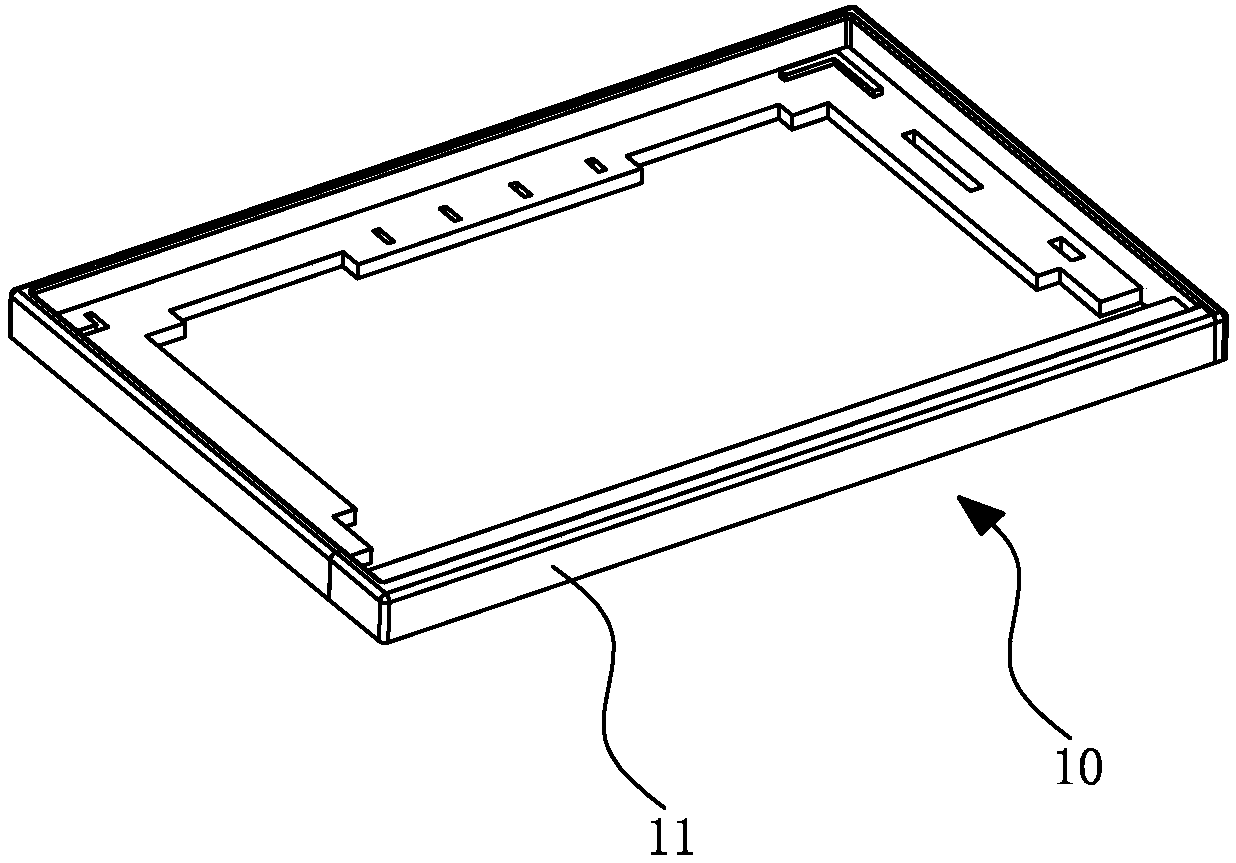

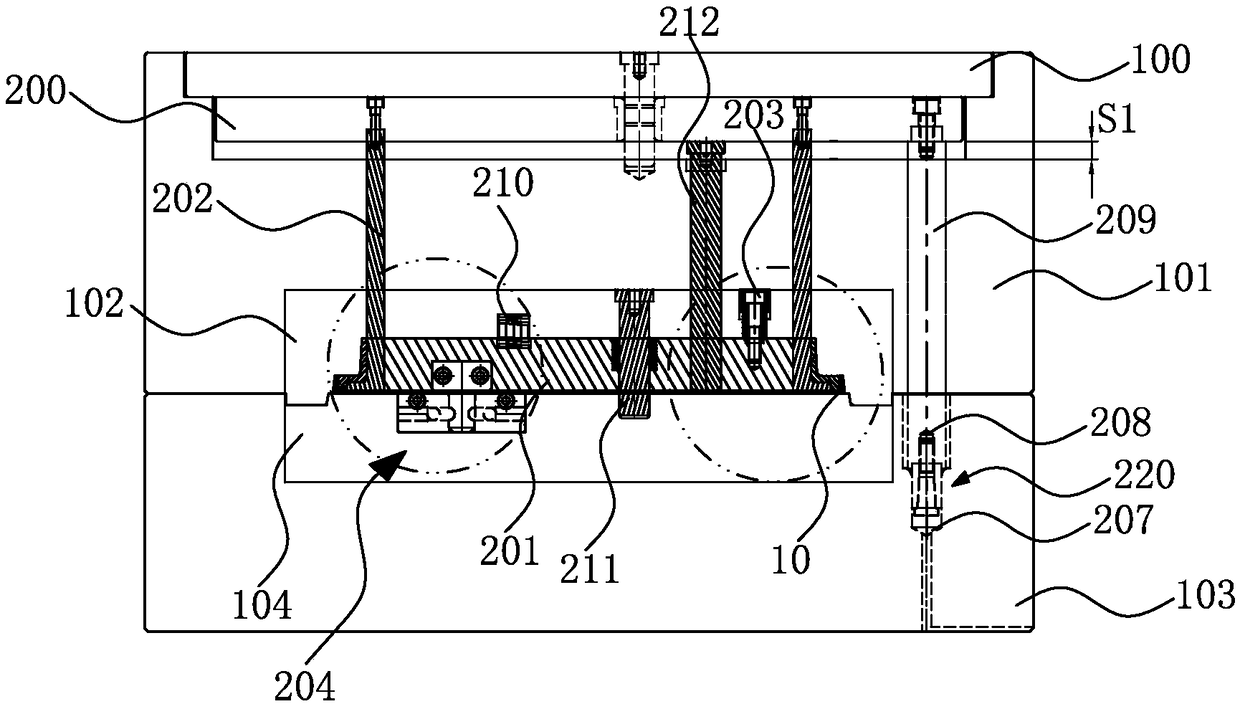

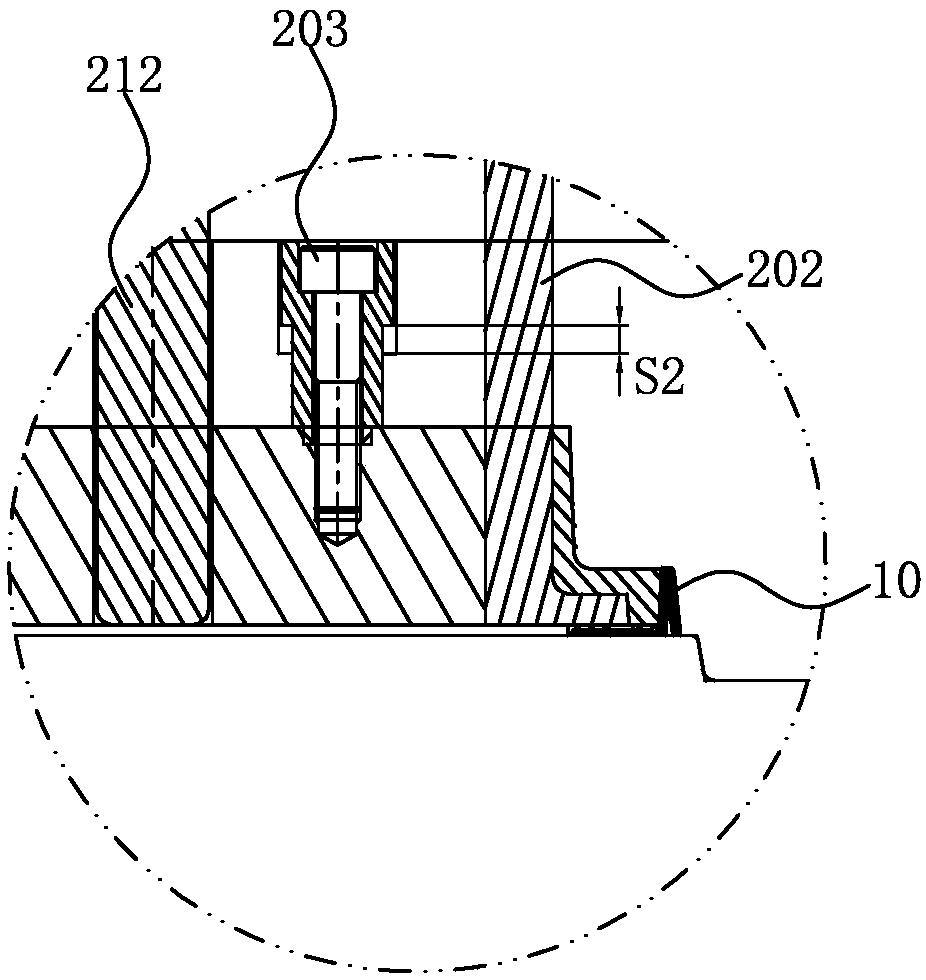

[0028] See Figure 2 to Figure 4 Shown, where figure 2 Draws a schematic diagram of the demolding structure of the present invention in a mold clamping state, image 3 Illustrated figure 2 A partial enlarged schematic diagram of Figure 4 Illustrated figure 2 Another partial enlarged schematic diagram of.

[0029] In a preferred embodiment, the demolding structure of the present invention is applied to a mold, and the mold includes an upper fixing plate 100, a female mold plate 101 under the upper fixing plate 100, a female mold core 102, a male mold plate 103, and a male mold plate. The mold core 104, the demolding structure includes:

[0030] The female mold ejector plate 200 is set in the female template 101, and a first movable stroke S1 is provided between the female mold ejector plate 200 and the female template 101, and the first movable stroke S1 may be 12 mm;

[0031] The elastic block 201 is set in the female mold core 102 and is set inside the product 10;

[0032] One e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap