Installation method of double-layer long-span steel structure corridor

An installation method and a large-span technology, which can be used in building construction, building material processing, construction, etc., and can solve problems such as inability to accommodate large-tonnage cranes and installation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

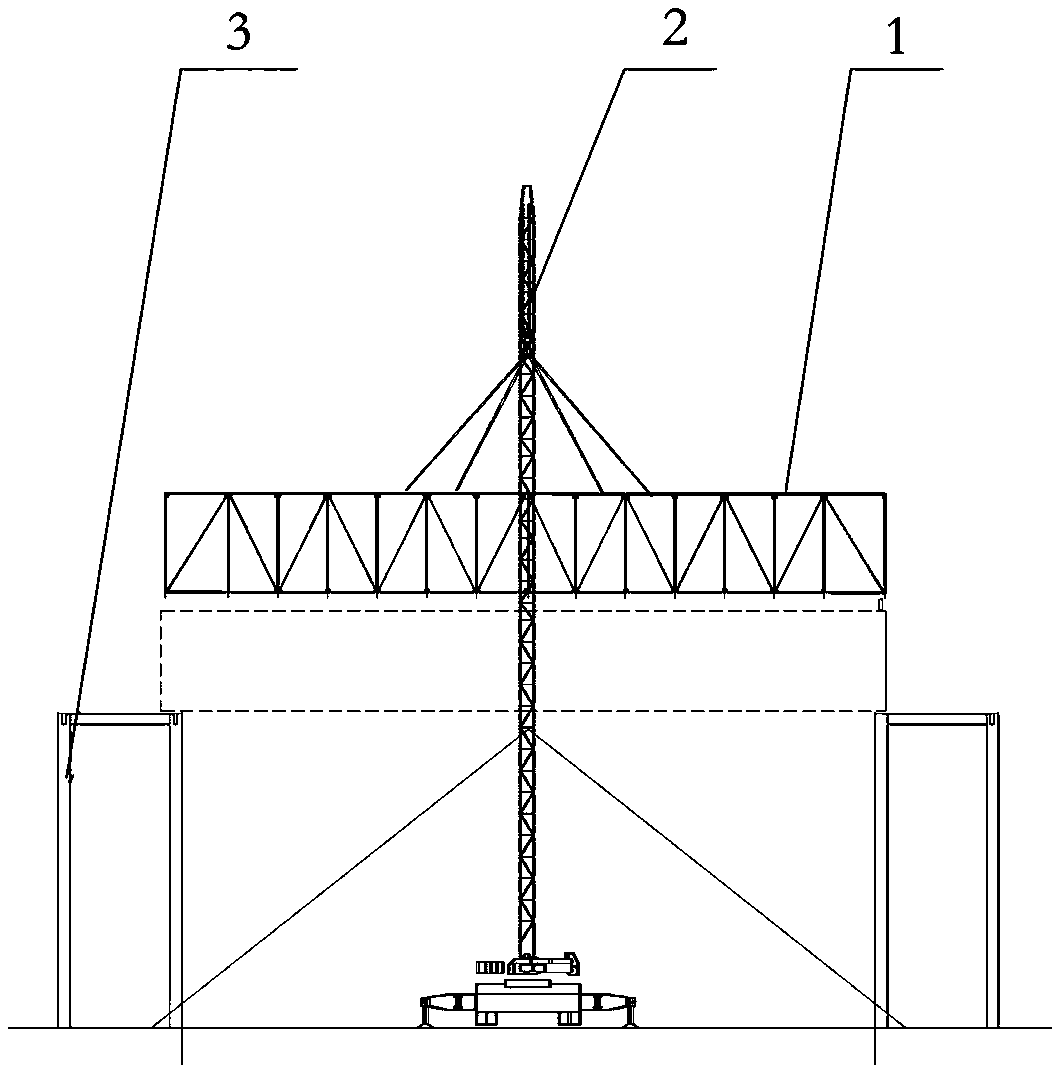

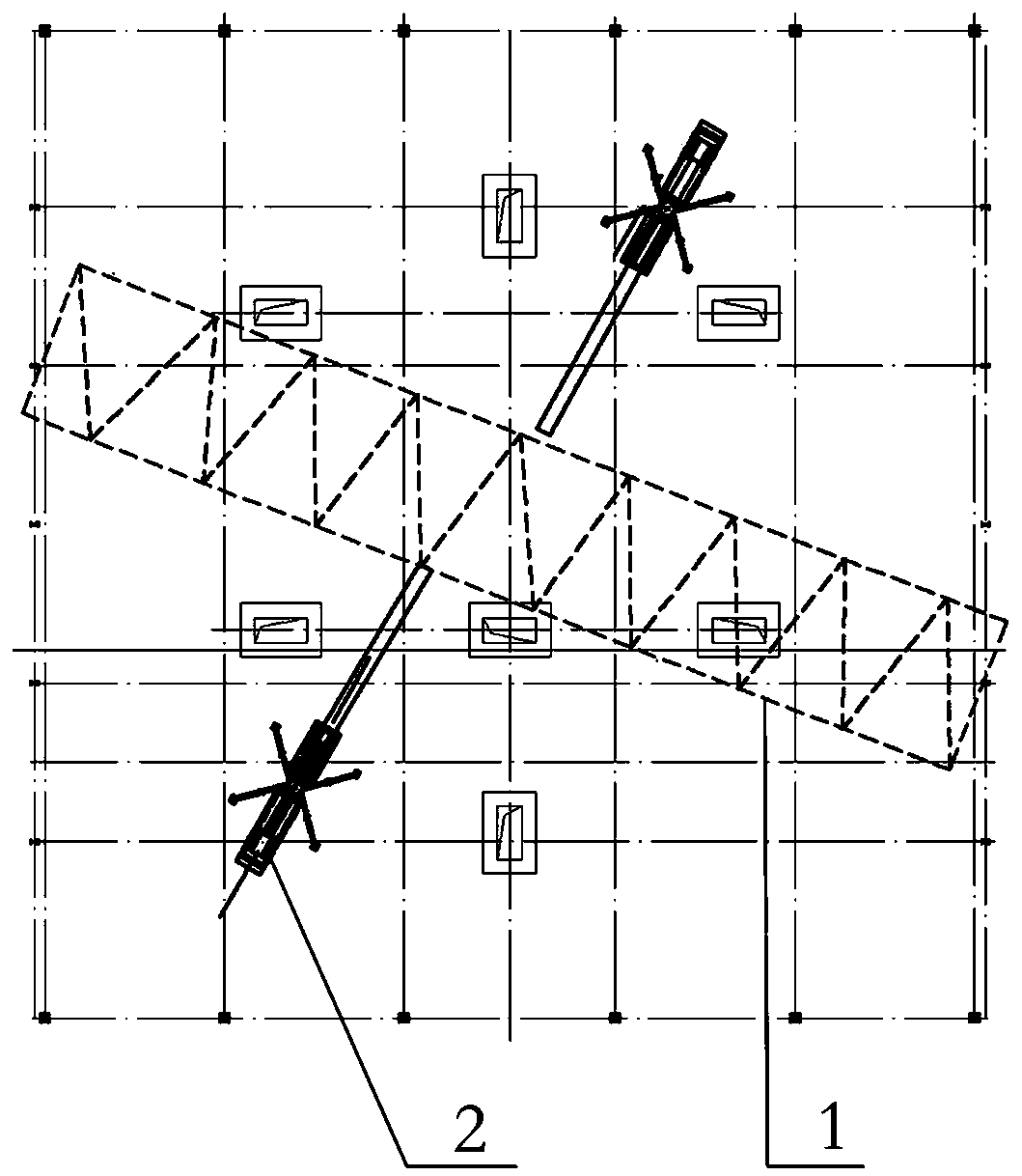

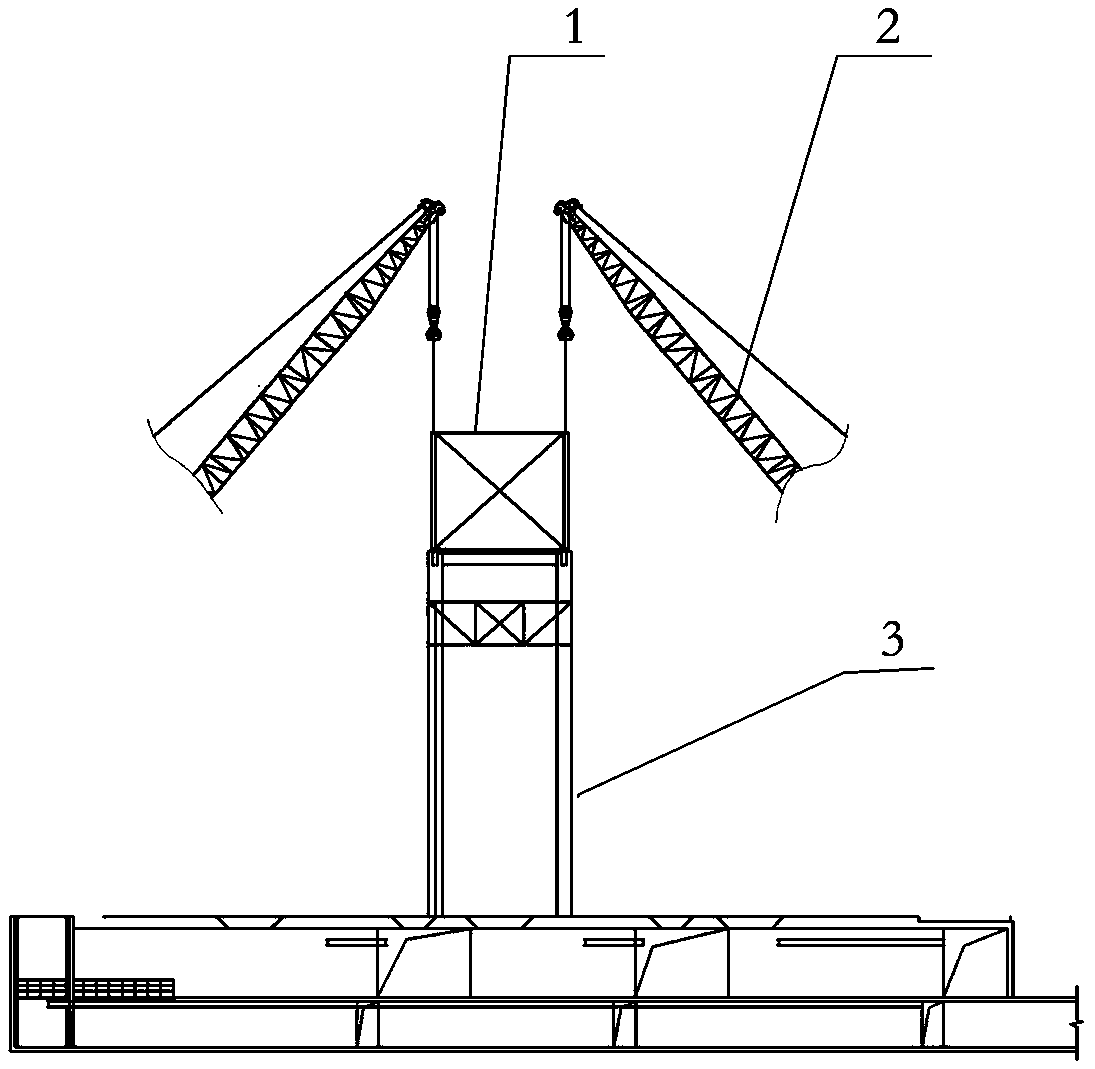

[0026] like Figure 1~Figure 4 As shown, a double-layer long-span steel structure corridor installation method includes the following steps:

[0027] a. The brackets 3 supporting the corridor are installed on the ground corresponding to the two ends of the corridor, and concrete construction is performed on the bottom of each bracket 3 when the brackets 3 are installed.

[0028] b. Splicing and assembling the middle and bottom of the lower corridor, and assembling it into a whole, this whole is called the lower corridor semi-integral 1. Two first truck cranes 2 with the same tonnage are selected, and the two first truck cranes are Cranes 2 are located on both sides of the width direction of the mid-span of the lower corridor semi-integral 1, that is, two first truck cranes 2 are located on both sides of the width direction of the lower corridor semi-integral 1 along the middle of its length direction, the first The projection of the boom axis of the automobile crane 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com