Extrusion type indoor fire hydrant

A extrusion type, fire hydrant technology, applied in fire rescue and other directions, to achieve the effect of preventing water leakage, long service life and reducing internal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

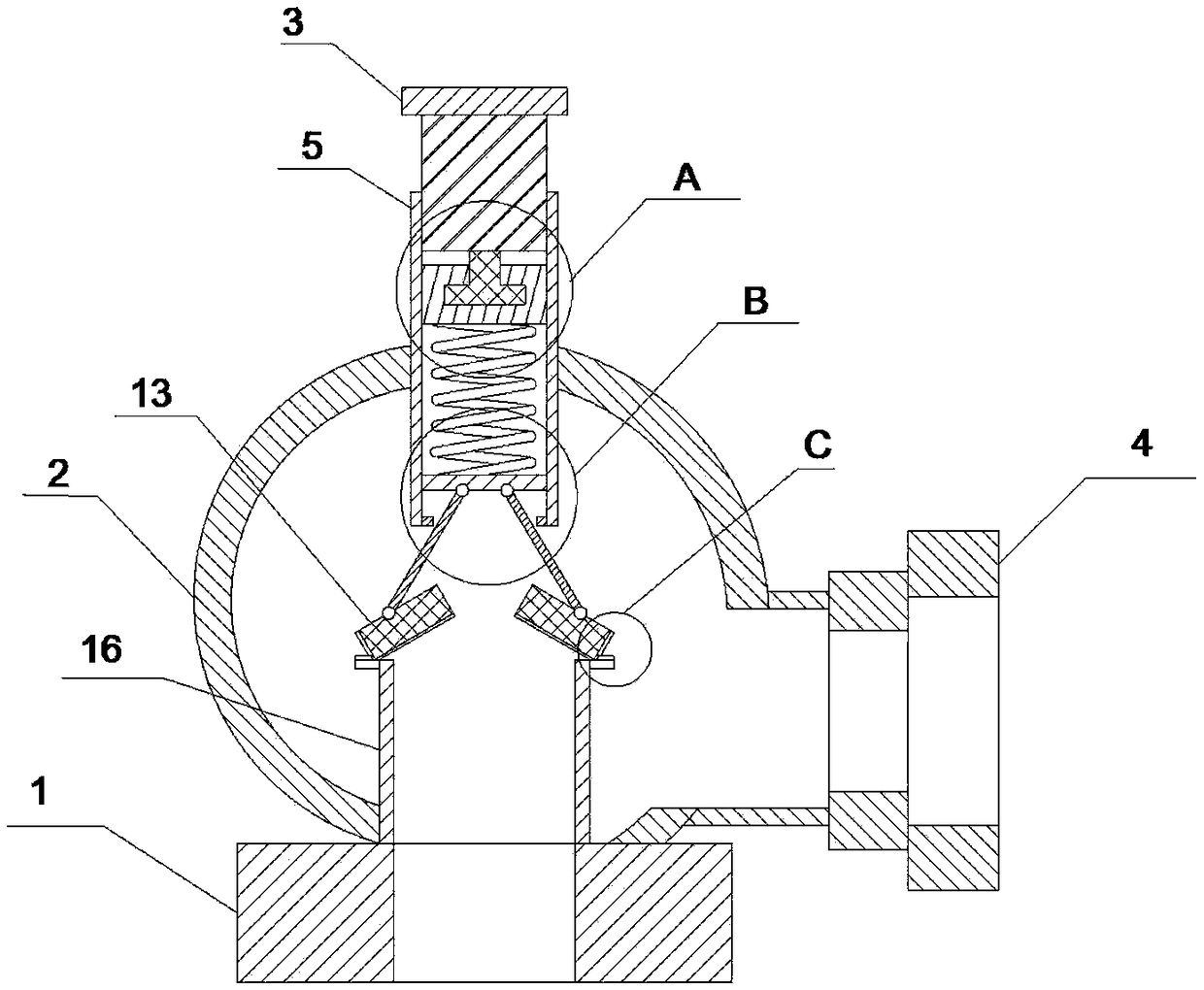

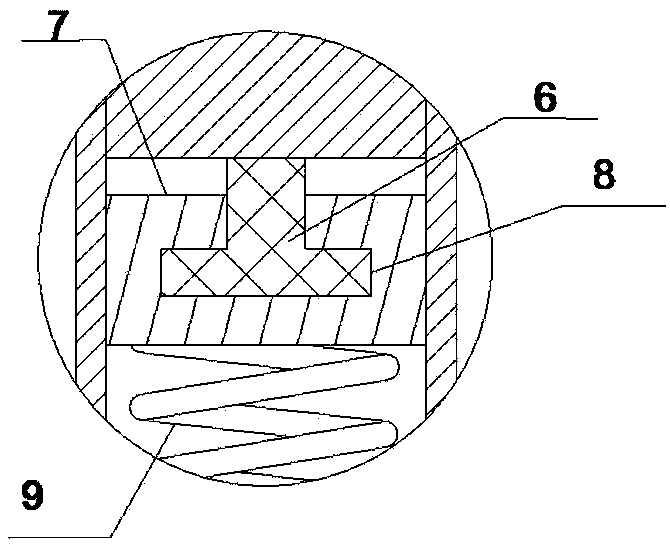

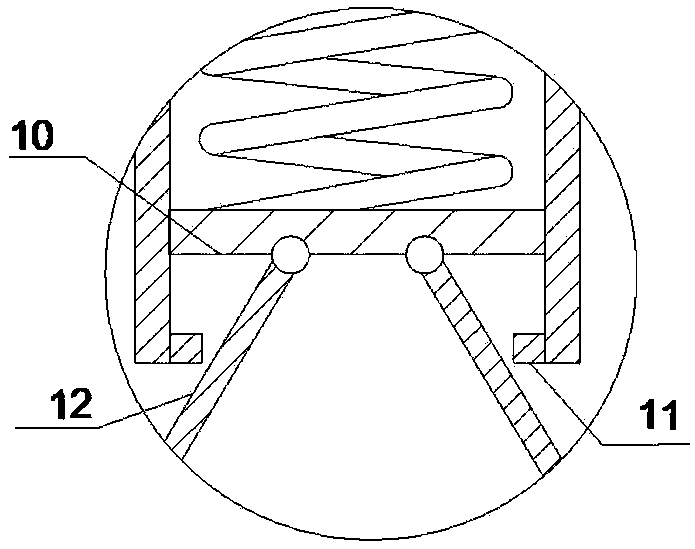

[0031] see Figure 1~4 , an extrusion type indoor fire hydrant, including a bolt body 2 with an inner cavity, characterized in that: the outer wall of the bolt body 2 is respectively connected with a base 1 and a connecting seat 4, and the base 1 is provided with an input channel 16 It communicates with the inner cavity of the plug body 2, and the connecting seat 4 is provided to communicate with the inner cavity of the plug body 2; one end port of the input channel 16 close to the inner cavity of the plug body 2 is hinged with a valve disc 13 that can open and close the input channel 16; A sleeve 5 is also connected to the outer wall of the bolt body 2, and the sleeve 5 and the base 1 are installed on opposite sides of the bolt body 2 respectively, and one end of the sleeve 5 located outside the bolt body 2 is threadedly connected with the adjusting bolt 3 ; The adjusting bolt 3 stretches into the sleeve 5, and its front end is provided with a first pressing plate 7, an adjus...

Embodiment 2

[0034] see Figure 1~4 , an extrusion type indoor fire hydrant, including a bolt body 2 with an inner cavity, characterized in that: the outer wall of the bolt body 2 is respectively connected with a base 1 and a connecting seat 4, and the base 1 is provided with an input channel 16 It communicates with the inner cavity of the plug body 2, and the connecting seat 4 is provided to communicate with the inner cavity of the plug body 2; one end port of the input channel 16 close to the inner cavity of the plug body 2 is hinged with a valve disc 13 that can open and close the input channel 16; A sleeve 5 is also connected to the outer wall of the bolt body 2, and the sleeve 5 and the base 1 are installed on opposite sides of the bolt body 2 respectively, and one end of the sleeve 5 located outside the bolt body 2 is threadedly connected with the adjusting bolt 3 ; The adjusting bolt 3 stretches into the sleeve 5, and its front end is provided with a first pressing plate 7, an adjus...

Embodiment 3

[0038] see Figure 1~4 , an extrusion type indoor fire hydrant, including a bolt body 2 with an inner cavity, characterized in that: the outer wall of the bolt body 2 is respectively connected with a base 1 and a connecting seat 4, and the base 1 is provided with an input channel 16 It communicates with the inner cavity of the plug body 2, and the connecting seat 4 is provided to communicate with the inner cavity of the plug body 2; one end port of the input channel 16 close to the inner cavity of the plug body 2 is hinged with a valve disc 13 that can open and close the input channel 16; A sleeve 5 is also connected to the outer wall of the bolt body 2, and the sleeve 5 and the base 1 are installed on opposite sides of the bolt body 2 respectively, and one end of the sleeve 5 located outside the bolt body 2 is threadedly connected with the adjusting bolt 3 ; The adjusting bolt 3 stretches into the sleeve 5, and its front end is provided with a first pressing plate 7, an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com