Novel fire hydrant

A fire hydrant, a new type of technology, used in fire rescue and other directions to reduce internal wear, prevent water, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

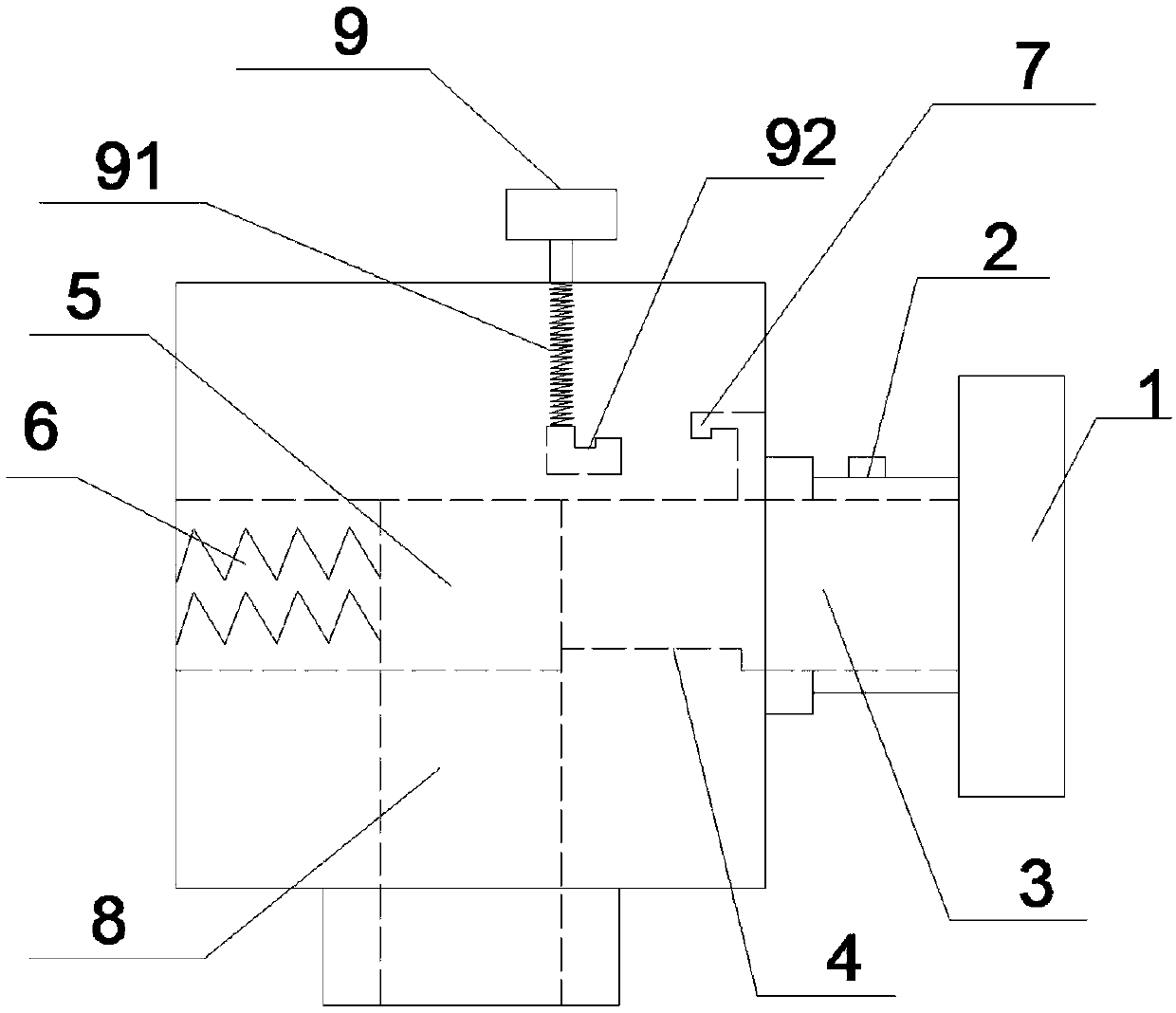

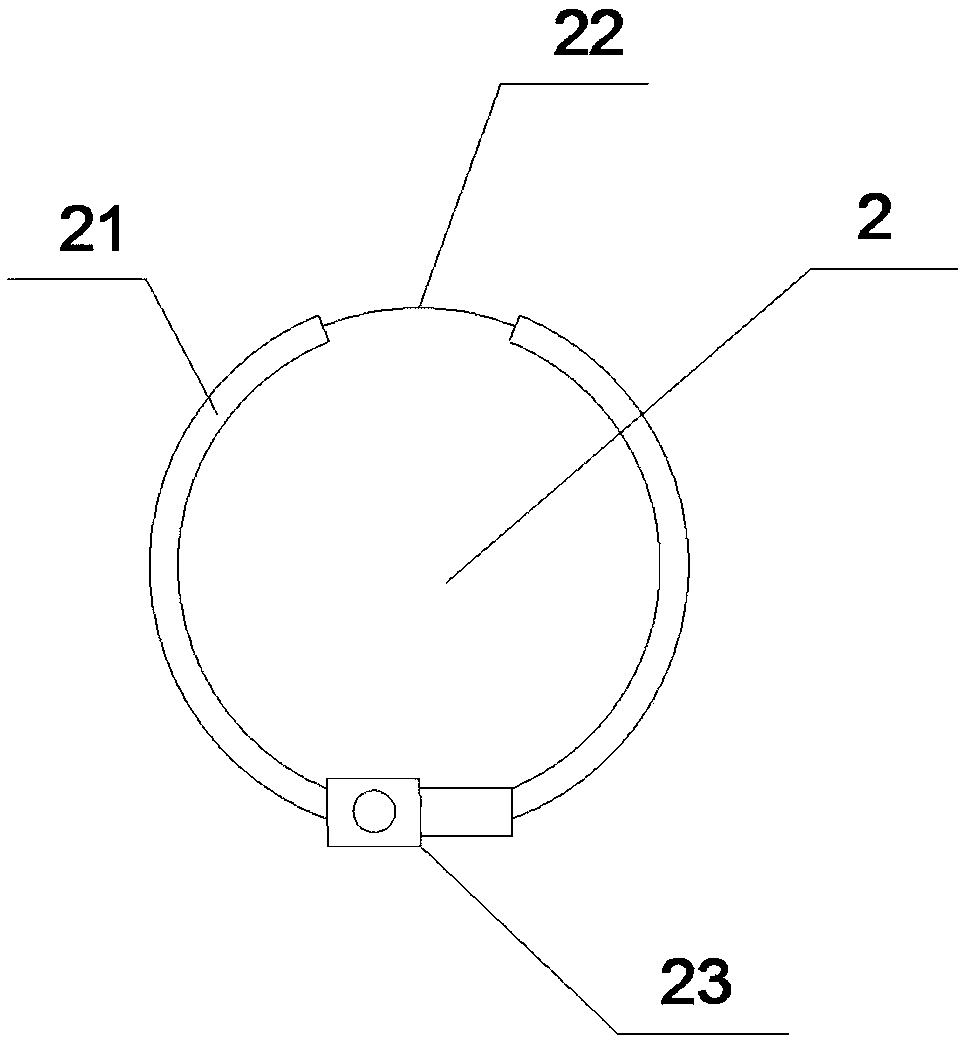

[0022] see Figure 1~2 , a new type of fire hydrant, comprising the connecting seat 1 and an internal moving water pipe 3, the connecting seat 1 is connected to the internal moving water pipe 3, the inner water pipe nozzle 4 is connected to a fixed water pipe 8; the internal moving water pipe 3 includes an internal Water pipe nozzle 4, magnetic block 5, spring tube 6, convex groove 7, described magnetic block 5 is cylindrical, and described magnetic block 5 is positioned at the junction of inner moving water pipe 3 and fixed water pipe 8, and described magnetic block 5 follows The inner moving water pipe 3 moves, and the outer diameter of the magnetic block 5 is equal to the outer diameter of the spring tube 6, and a fixed water pipe 8 is arranged below the magnetic block 5, and the outer diameter of the fixed water pipe 8 is the same as that of the magnetic block 5. The top of the internal moving water pipe 3 is provided with a convex groove 7, and the convex groove 7 moves w...

Embodiment 2

[0025] see Figure 1~2 , a new type of fire hydrant, comprising the connecting seat 1 and an internal moving water pipe 3, the connecting seat 1 is connected to the internal moving water pipe 3, the inner water pipe nozzle 4 is connected to a fixed water pipe 8; the internal moving water pipe 3 includes an internal Water pipe nozzle 4, magnetic block 5, spring tube 6, convex groove 7, described magnetic block 5 is cylindrical, and described magnetic block 5 is positioned at the junction of inner moving water pipe 3 and fixed water pipe 8, and described magnetic block 5 follows The inner moving water pipe 3 moves, and the outer diameter of the magnetic block 5 is equal to the outer diameter of the spring tube 6, and a fixed water pipe 8 is arranged below the magnetic block 5, and the outer diameter of the fixed water pipe 8 is the same as that of the magnetic block 5. The top of the internal moving water pipe 3 is provided with a convex groove 7, and the convex groove 7 moves w...

Embodiment 3

[0028] see Figure 1~2 , a new type of fire hydrant, comprising the connecting seat 1 and an internal moving water pipe 3, the connecting seat 1 is connected to the internal moving water pipe 3, the inner water pipe nozzle 4 is connected to a fixed water pipe 8; the internal moving water pipe 3 includes an internal Water pipe nozzle 4, magnetic block 5, spring tube 6, convex groove 7, described magnetic block 5 is cylindrical, and described magnetic block 5 is positioned at the junction of inner moving water pipe 3 and fixed water pipe 8, and described magnetic block 5 follows The inner moving water pipe 3 moves, and the outer diameter of the magnetic block 5 is equal to the outer diameter of the spring tube 6, and a fixed water pipe 8 is arranged below the magnetic block 5, and the outer diameter of the fixed water pipe 8 is the same as that of the magnetic block 5. The top of the internal moving water pipe 3 is provided with a convex groove 7, and the convex groove 7 moves w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com