A special cable for oil well exploration

A special cable and oil well technology, applied in power cables, insulated cables, insulation of conductors/cables, etc., can solve problems such as optical fiber cannot be effectively protected, cables are easily twisted and deformed, and copper wires are twisted and twisted, so as to reduce detection and maintenance costs. , Improve the impact buffer effect, reduce the effect of internal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

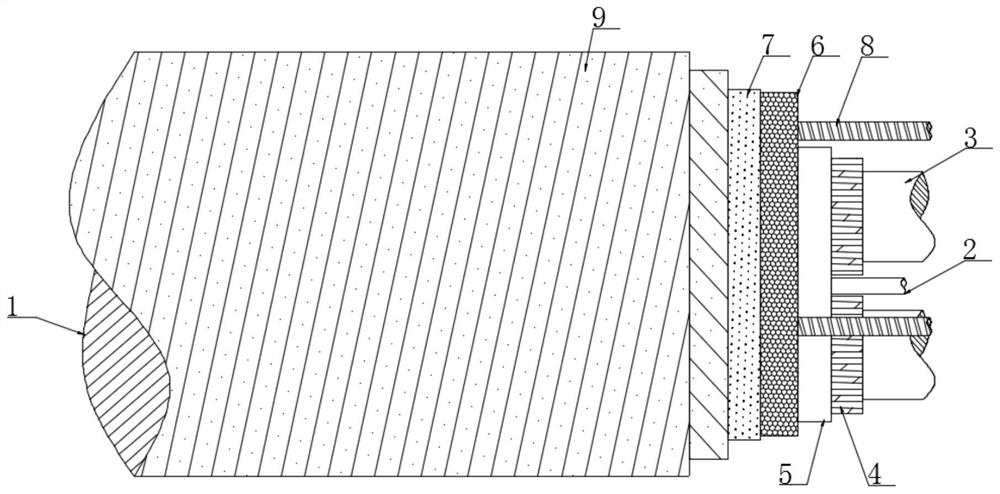

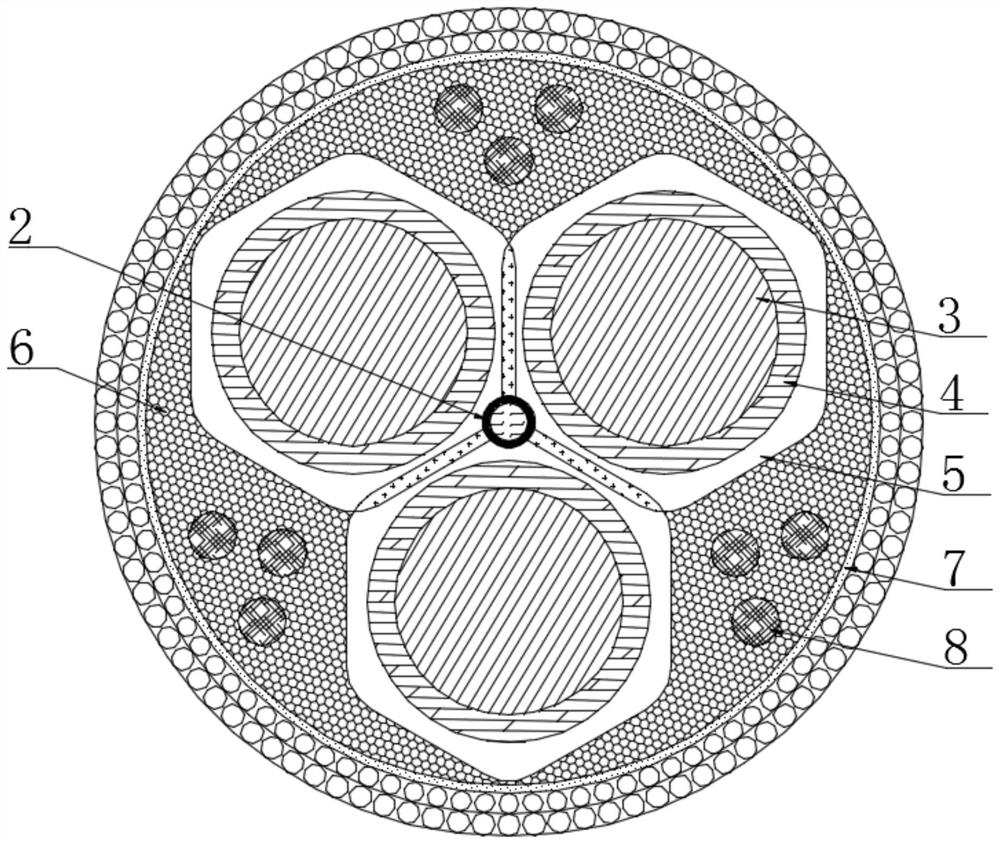

[0034] according to Figure 1-5 The shown special cable for oil well exploration includes a cable body 1, an optical fiber sleeve 2 is provided at the axis of the cable body 1, a copper conductor 3 is provided outside the optical fiber sleeve 2, and a copper conductor 3 is provided outside the copper conductor 3. Insulating layer 4, the outer side of the insulating layer 4 is provided with a connecting sheath 5, the outer side of the connecting sheath 5 is provided with a buffer sheath 6, the outer side of the buffering sheath 6 is provided with an oil-resistant cushion layer 7, and the buffering sheath 6 is provided with a load-bearing fiber 8 inside, and the outer side of the oil-resistant cushion 7 is provided with an armor layer 9;

[0035] The number of the copper conductors 3 is set to three, and the three annular arrays of the copper conductors 3 are distributed on the outside of the optical fiber sleeve 2, the cross-sectional shape of the connecting sleeve layer 5 is s...

Embodiment 2

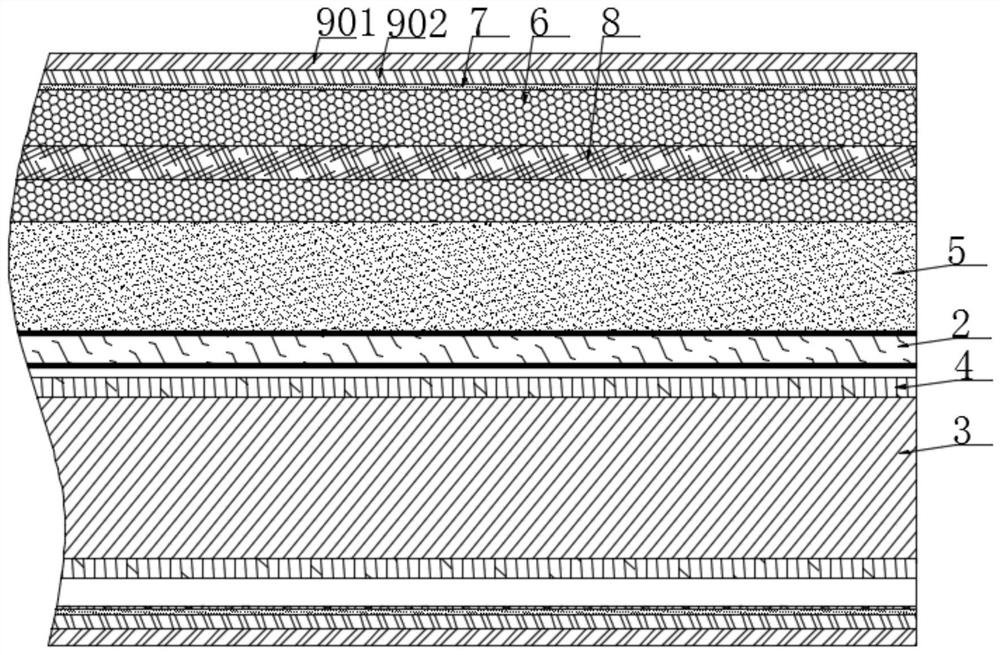

[0051] according to Figure 6-7 The shown special cable for oil well exploration includes a cable body 1, three copper conductors 3 are arranged inside the cable body 1, an insulating layer 4 is arranged on the outer side of the copper conductor 3, and an insulating layer 4 is arranged on the outer side of the insulating layer 4. There is a connecting sheath 5, a buffer sheath 6 is provided on the outside of the connecting sheath 5, an oil-resistant cushion layer 7 is provided on the outside of the buffer sheath 6, and a load-bearing fiber 8 is arranged inside the buffer sheath 6, and the oil-resistant The outer side of the cushion layer 7 is provided with an armor layer 9;

[0052] The three copper conductors 3 are distributed in a straight line, and the cross-sectional shape of the connecting sleeve layer 5 is set to be hexagonal, and the two adjacent connecting sleeve layers 5 are bonded, and the two connecting sleeve layers 5 are glued together. Both sides of the junction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com