An automatic painting equipment for the arc surface of oval parts

An automatic painting and arc surface technology, applied in the direction of spraying device, etc., can solve the problems that it is difficult to paint the arc surface of elliptical parts, and the distance between the centers of elliptical parts is not constant, so as to achieve convenient automatic painting and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]In order to better understand the technical solution of the present invention, the present invention will be more clear and more complete, and the embodiments described are only part of the present invention. Non-all, based on the present embodiment, those skilled in the art without paying creative labor, all of which are in the scope of the invention.

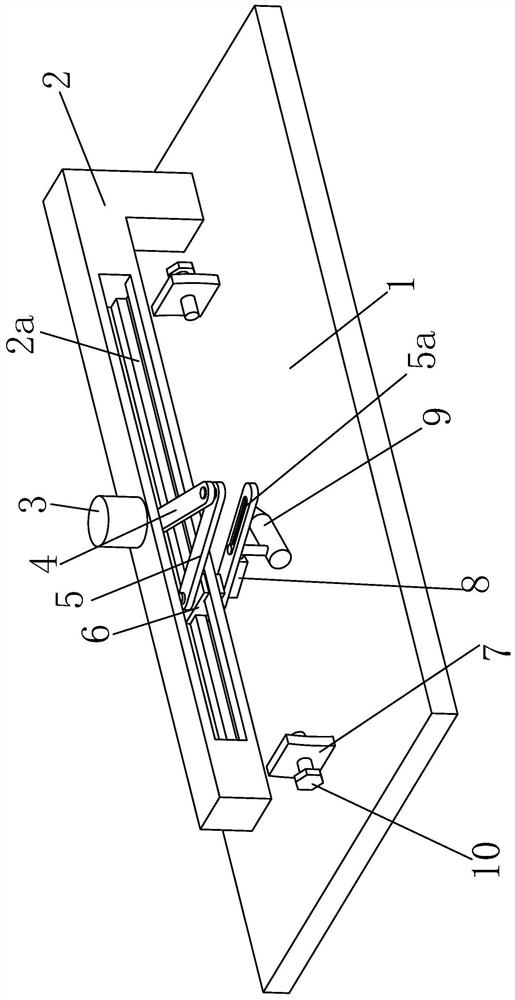

[0015]Such asfigure 1As shown, an automatic painting apparatus for an elliptical part arc surface, including a bottom plate 1 and a secondary frame 2 in the bottom plate 1, and a motor 3 is attached to the upper center region of the secondary end, and the motor 3 is connected. The upper rocker 4, the upper rocker 4 hinges the U-shaped downstool 5 on the side of the motor 3, and the lower rocker 5 is hinged from one side of the upper and the rocker 4. Block 6, the lower portion of the secondary frame opens the main slide 2a sliding the main slider 6 horizontally. The upper rocker 4 is adjacent to the length of the lower rocker 5.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com