Changeover valve

A technology for switching valves and valve seats, used in multi-port valves, valve devices, engine components, etc., to solve problems such as wrong assignment of operating rods, changes in owner's plans, and wrong installation of wall connection housings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

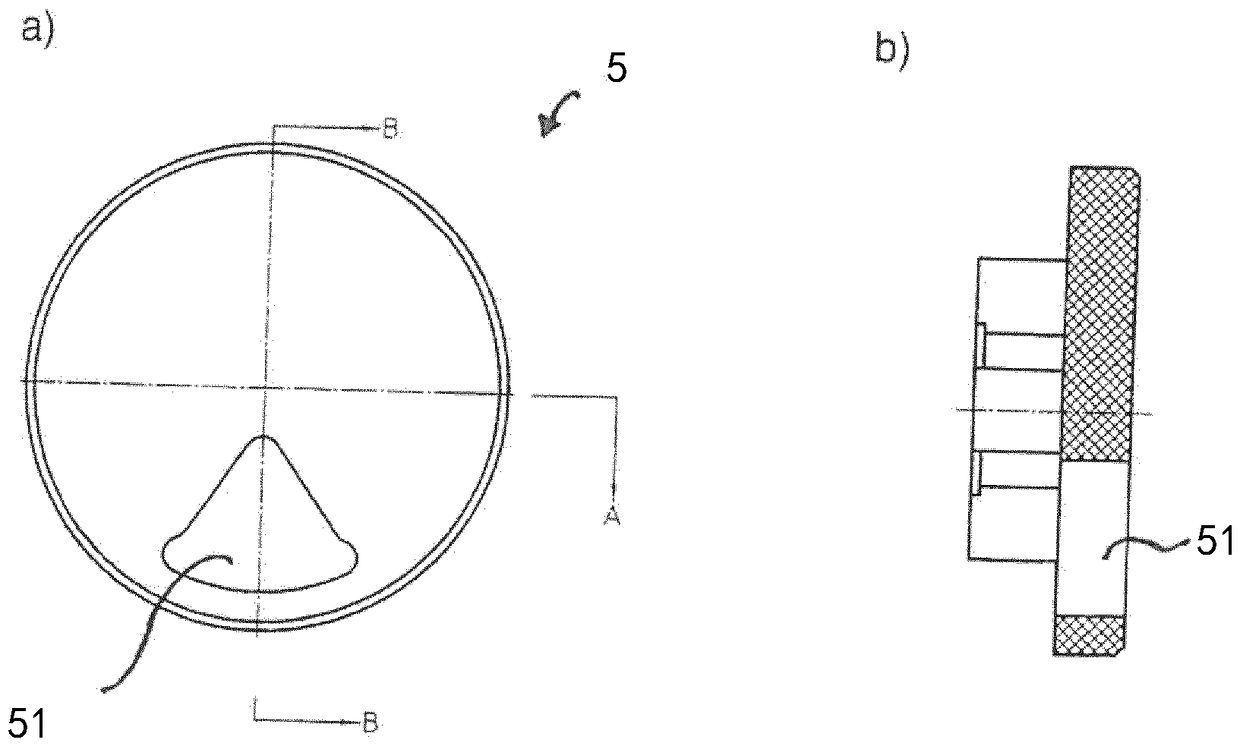

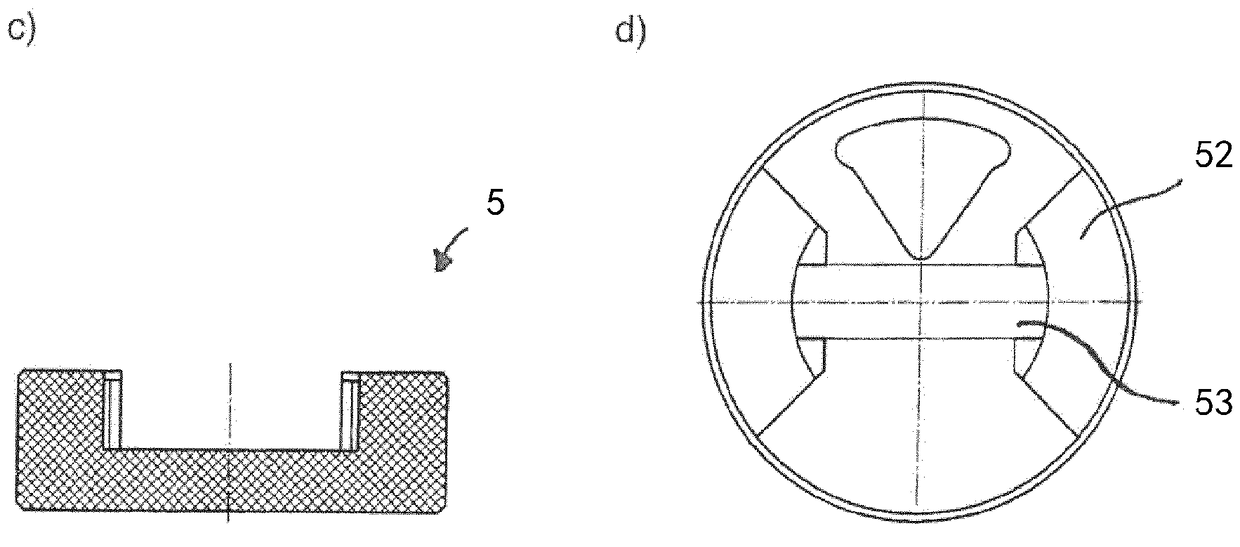

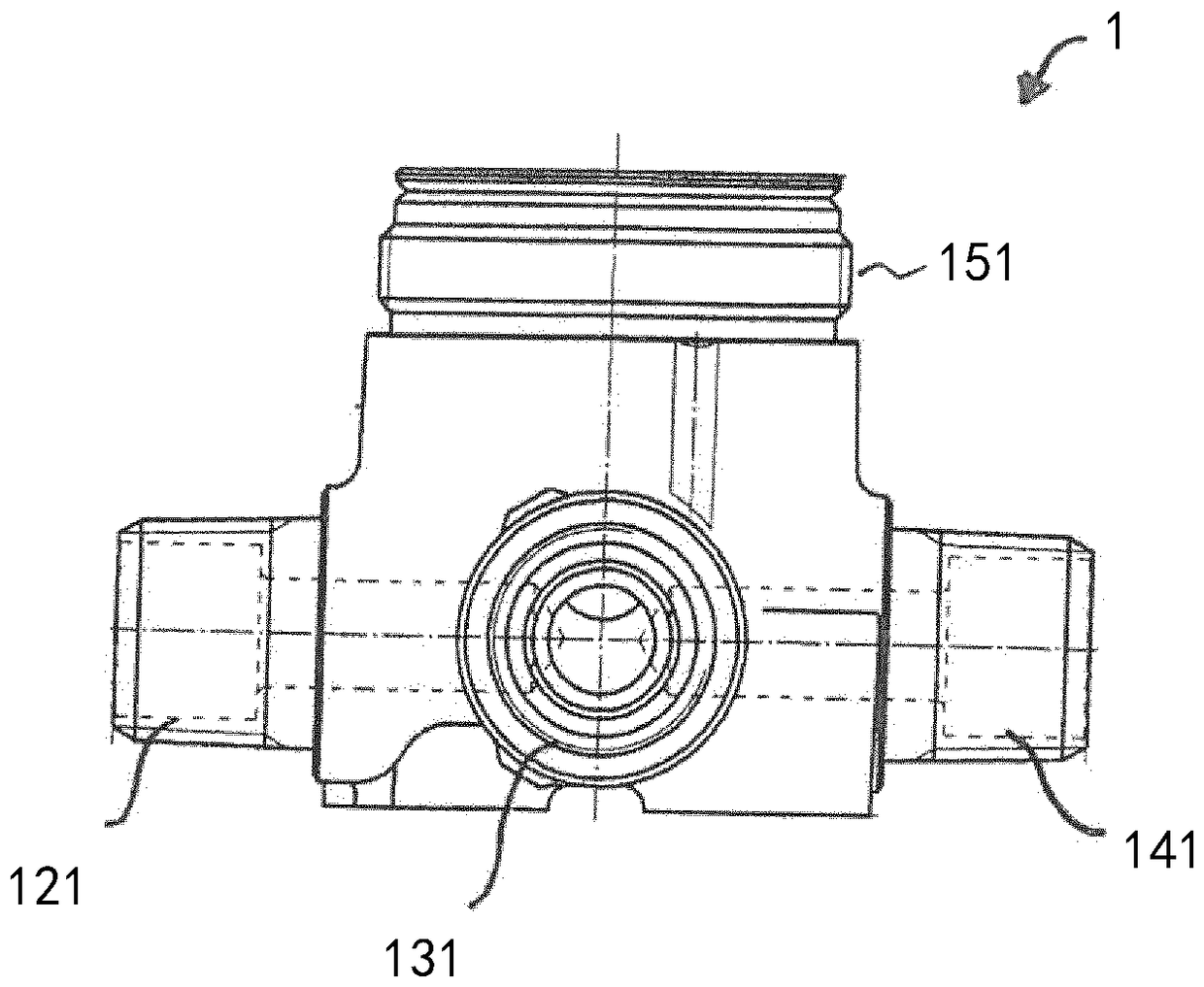

[0033] The switchover valve chosen as the embodiment essentially consists of a wall connection housing 1 which accommodates the upper part 2 of the valve.

[0034] The wall connection housing 1 is made of brass in this exemplary embodiment and comprises a cup-shaped valve chamber 15 into which a valve seat 16 is inserted on the bottom side. Three outlet channels 12 , 13 , 14 , which are each connected to outlet connections 121 , 131 , 141 formed on the outside of valve chamber 15 , open into valve seat 16 offset by 120° from one another. Furthermore, an inlet connection 111 , which is connected to an inlet channel 11 , which opens laterally into the valve chamber 15 , is integrally formed on the outside of the valve chamber 15 . The input connector 111 and the three output connectors 121 , 131 , 141 are formed at the valve chamber 15 staggered from each other by 90° and are used for connecting fluid inflow or outflow lines. Furthermore, three positioning holes 17 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com