A converter oxygen lance

A converter oxygen lance and gun body technology, applied in the manufacture of converters, etc., can solve the problems of inability to intuitively detect whether the oxygen lance is tilted, inconvenient oxygen lance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

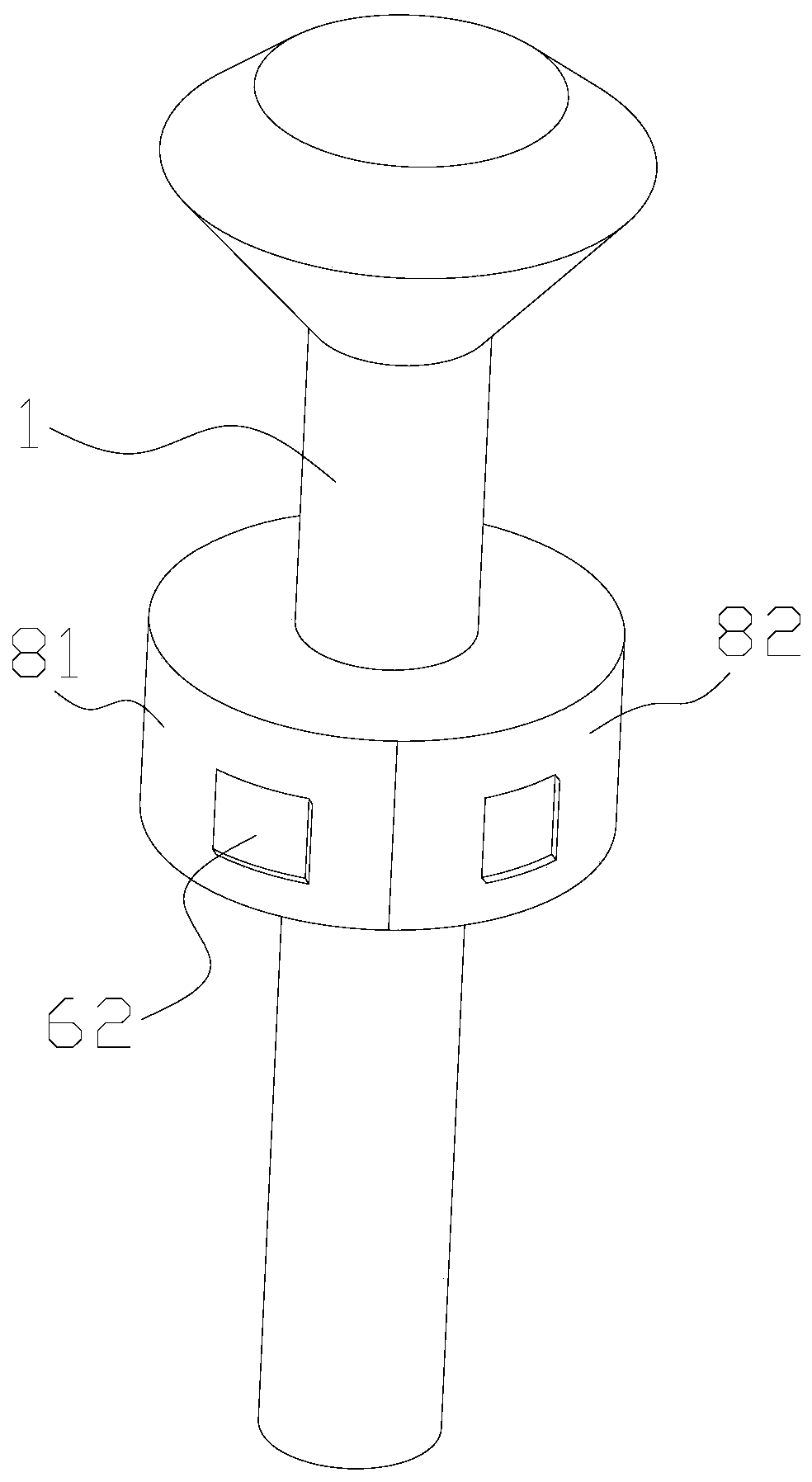

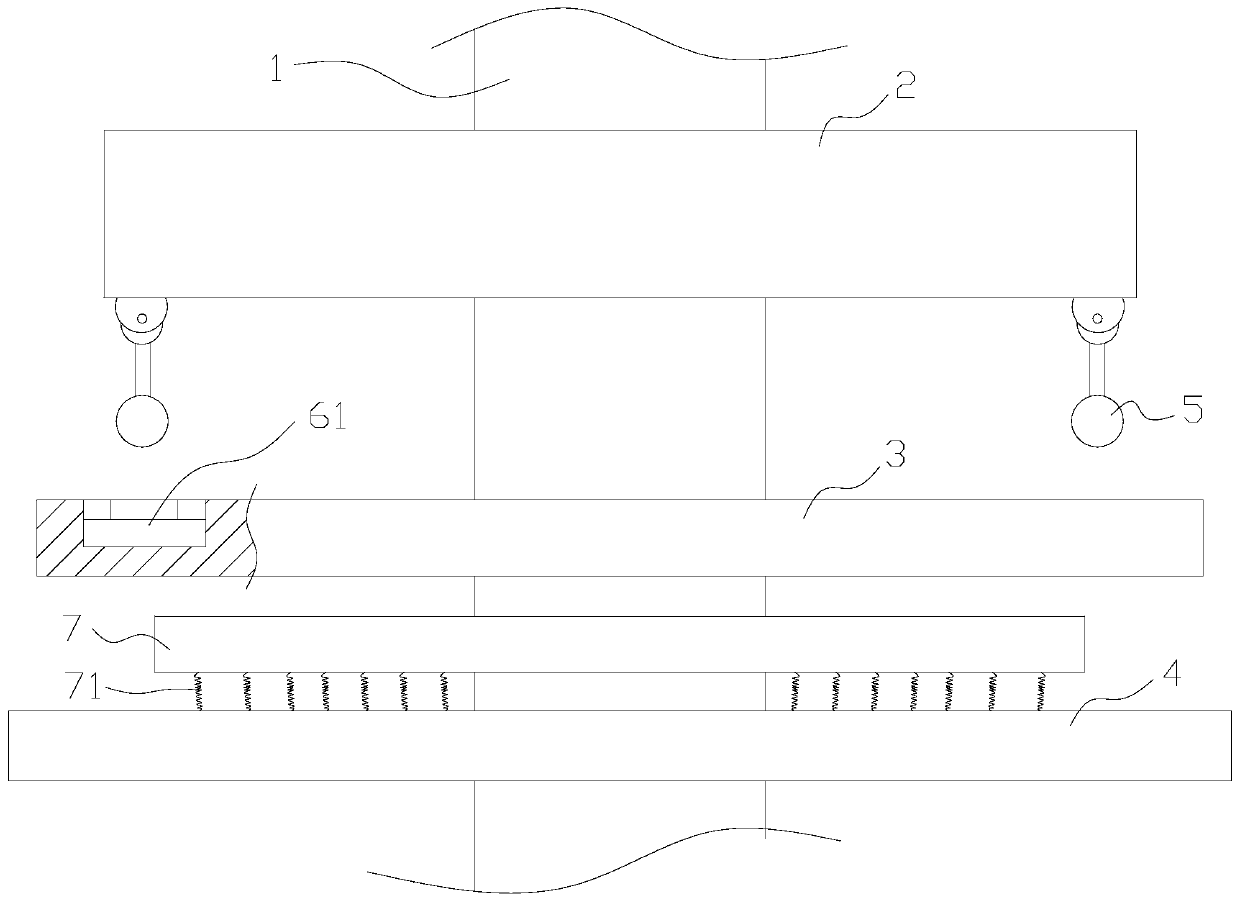

[0021] A converter oxygen lance, refer to figure 1 with figure 2 , including a gun body 1, on which a fixed ring 2 and a detection ring 3 are sheathed. The fixed ring 2 is in interference fit with the gun body 1 , the detection ring 3 is in clearance fit with the gun body 1 , and the detection ring 3 is fixed under the fixed ring 2 . During the use of the oxygen lance, the lifting and fixing of the oxygen lance is realized by the lifting trolley, and the detection ring 3 and the lifting trolley are fixed, which reduces the impact on the detection ring 3 when the gun body 1 is tilted. Several support rods can be arranged between the lifting trolley and the lower end surface of the detection ring 3, and the two ends of the support rods are fixed with the lifting trolley and the detection ring 3 screws respectively. In order to reduce the damage to the fixed ring 2 caused by the temperature of the gun body 1 during operation, the inner wall of the fixed ring 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com