Optical detection method for microstructure with large aspect ratio

A technology of optical detection and micro-aspect ratio, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of difficult detection of microstructure side walls, achieve rapid detection, realize computer identification and data processing, and easy computer identification and the effect of data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

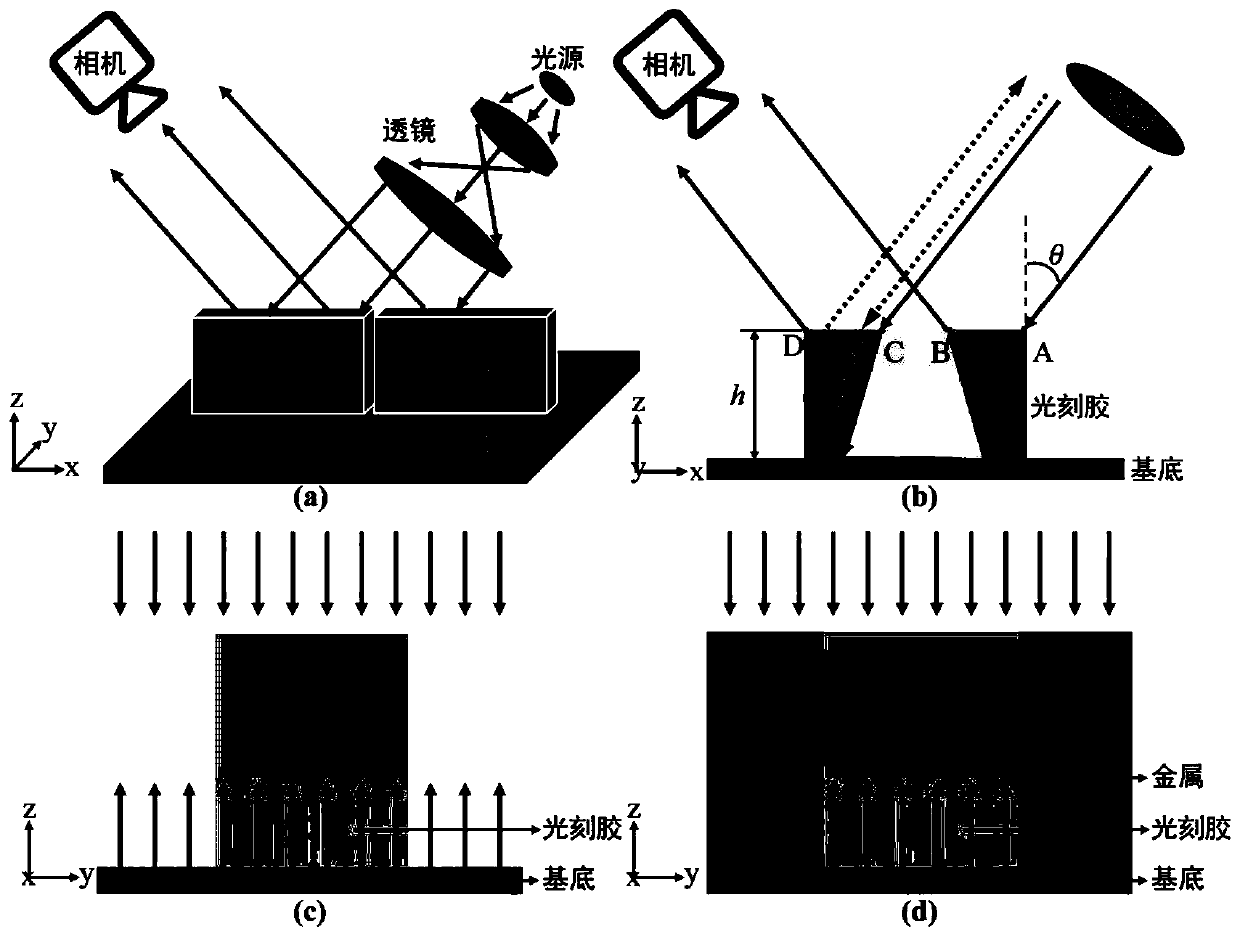

[0027] The invention detects the sidewall morphology of the microstructure with a large aspect ratio based on the different reflections of the microstructures of different sidewalls to incident light. Its detection principle is as figure 1 shown.

[0028] figure 1 (a) is a schematic diagram of the optical detection system, figure 1 (b) is a cross-sectional view of the microstructure along the length direction. A beam of incident light is incident along the length direction of the microstructure, and a camera is placed at the light exit position to observe the reflection of the light. The light enters the photoresist from the rightmost point A of the microstructure, reaches the substrate surface and reflects back, and then exits from the B point; the light enters from the C point, and exits from the leftmost point D; After refraction, it rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com