Small and medium size multifunctional silage maize harvester and self-assembly method

A multi-functional, silage machine technology, applied in the field of agricultural machinery, can solve the problems of silage equipment with few functions, inconvenient installation and disassembly, and difficulty in disassembly, and achieve the effects of saving manpower, simple disassembly, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

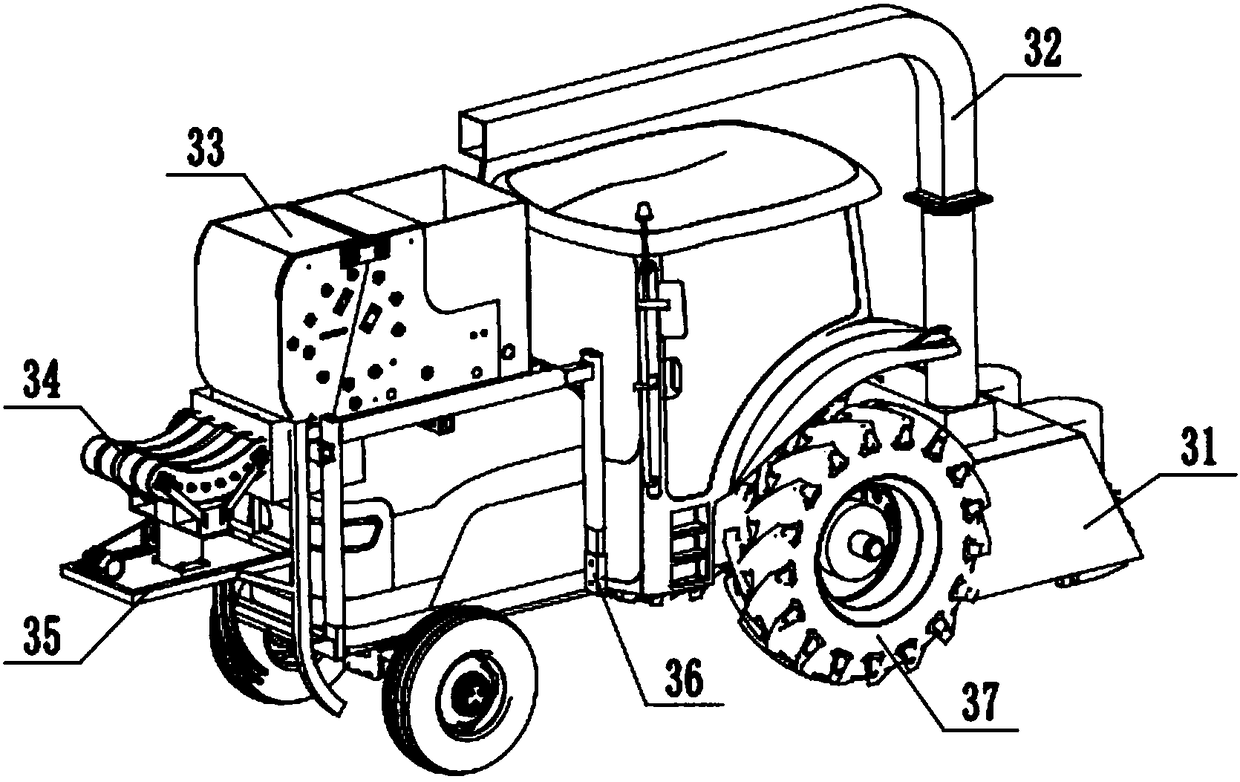

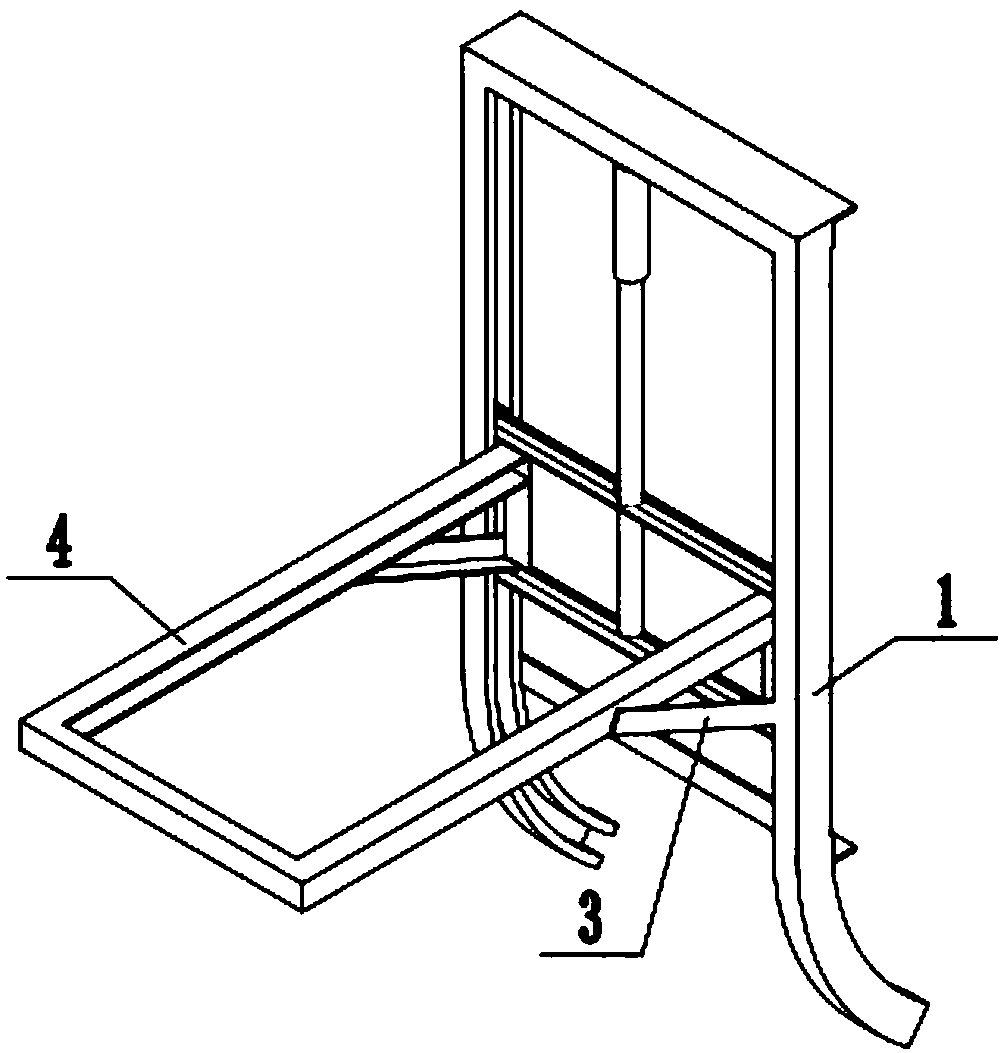

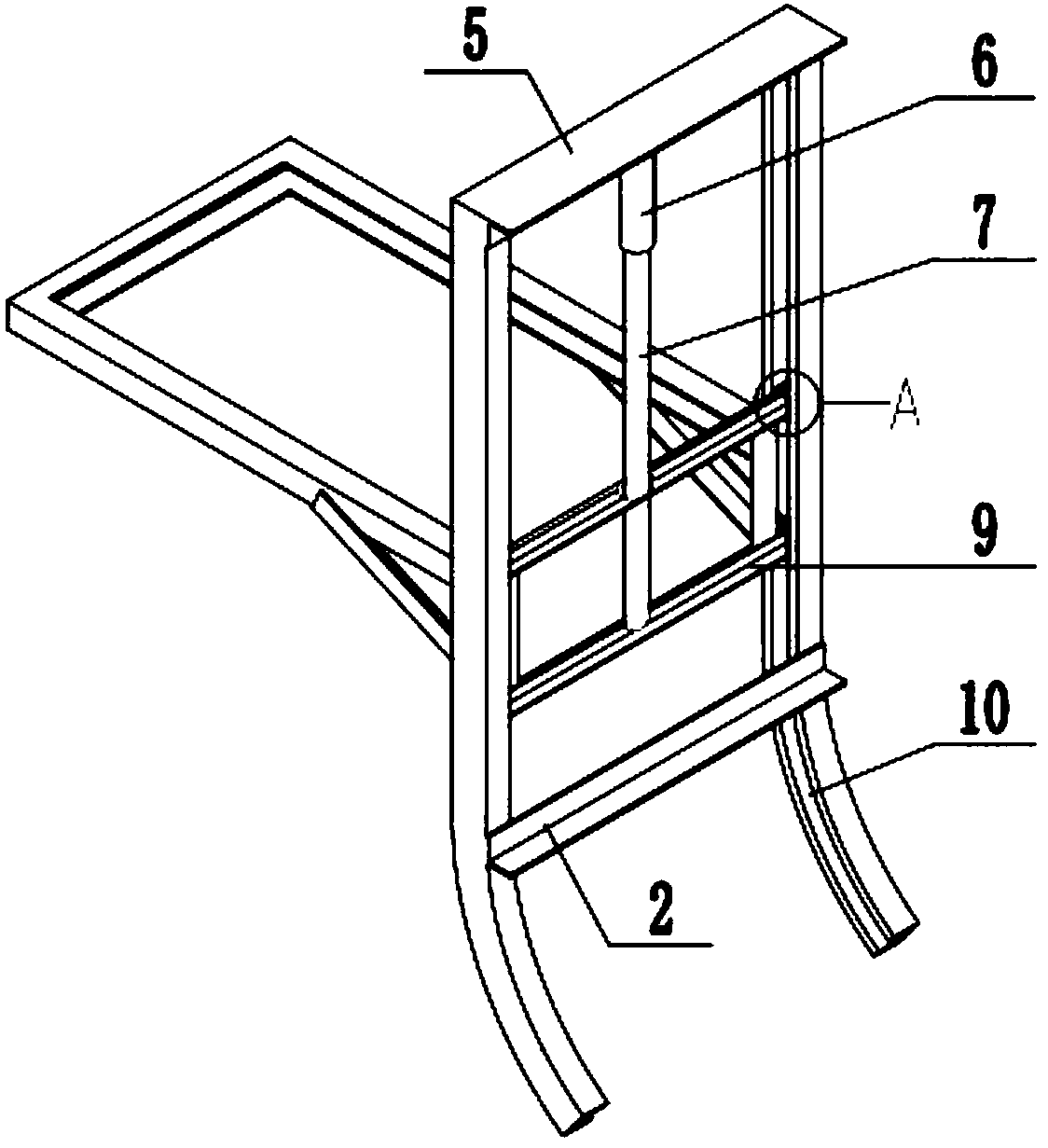

[0043] like Figure 1-9 Shown, a kind of small and medium-sized multifunctional silage machine, comprises header 31, throwing cylinder 32, bundling device 33, coating device 34, elevating device 35, telescopic device 36, tractor 37, described header 31 and tractor The rear suspension of 37 is connected, and described telescopic device 36 is connected with the front end of tractor 37, and the lower end of described strapping device 33 is connected with telescopic device 36 by slide block 39, and strapping device 33 comprises collector and strapping machine, collector Connected with the baler, the lifting device 35 is connected with the telescopic device 36, the coating device 34 is connected with the lifting device 35, one end of the throwing cylinder 32 is connected with the header 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com