Vehicle for a magnetic levitation track

A transportation tool and magnetic levitation technology, which is applied in sliding/floating railway systems, transport passenger cars, transport passenger cars, etc., can solve the problems of suspension device structure cost, small mobility, etc., and achieve comfortable driving operation, good rigidity and driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

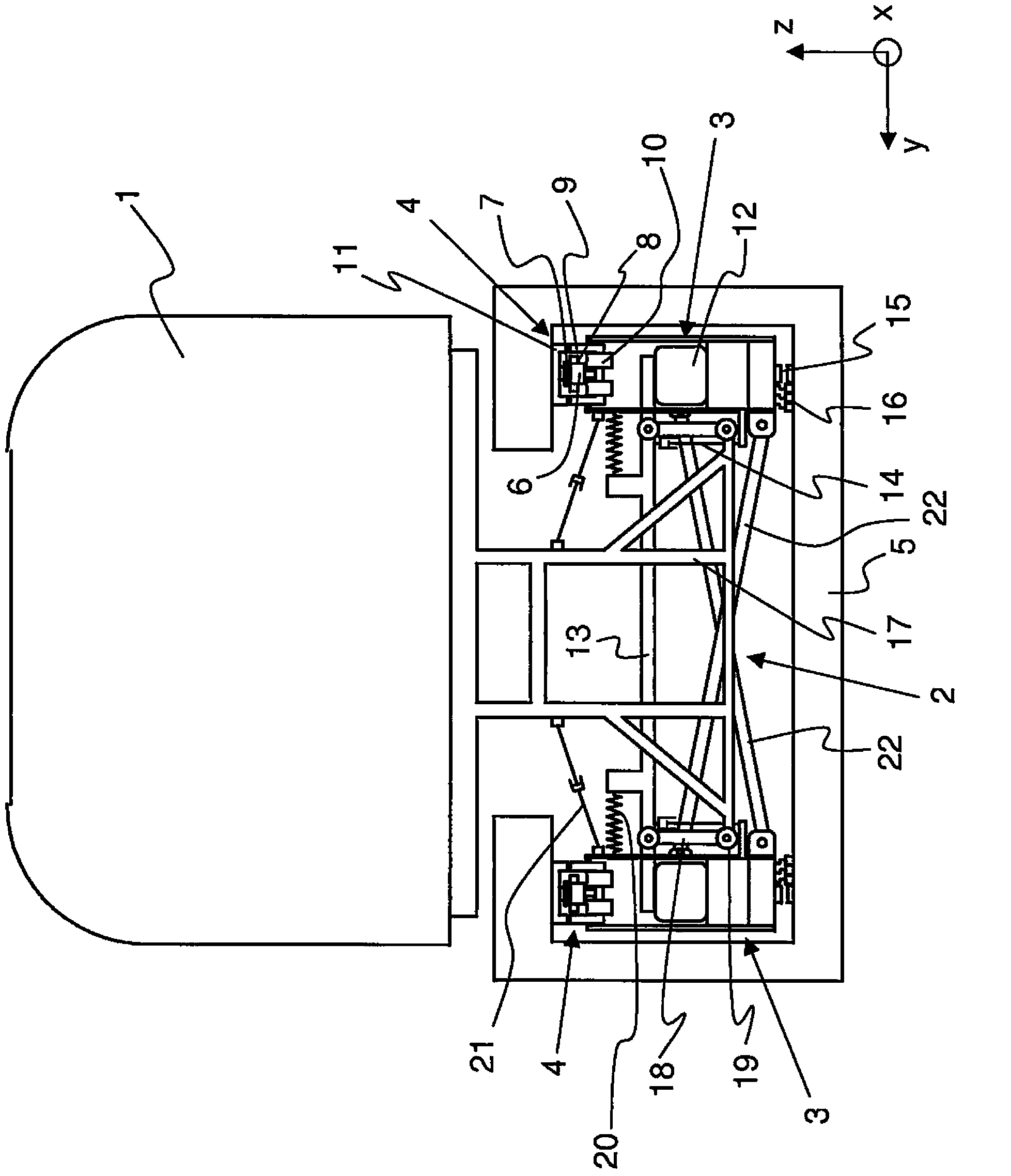

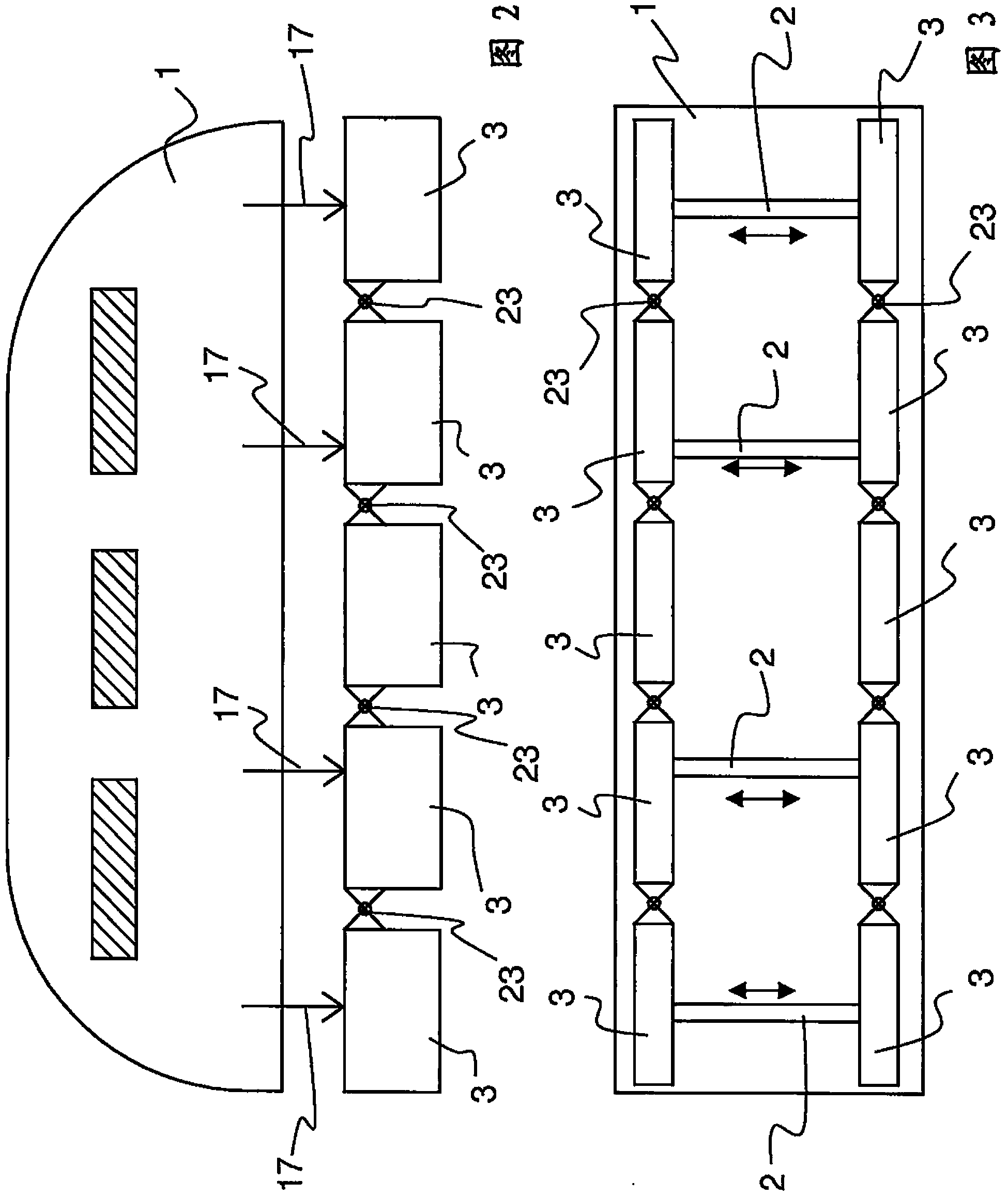

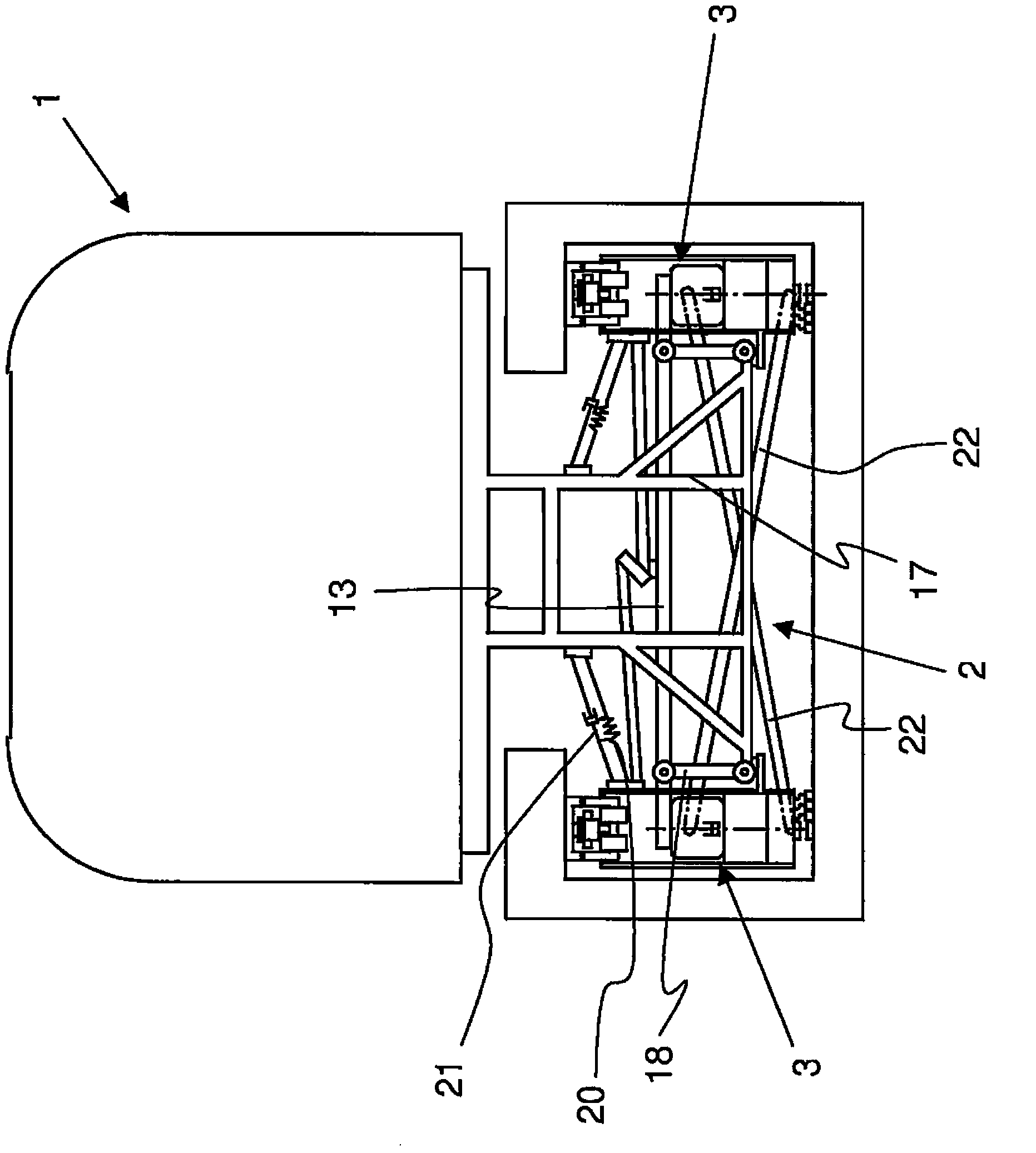

[0034] figure 1 shows a cross-sectional view through a vehicle for a maglev railway according to the invention, the vehicle having a car body 1, a suspension 2 and a plurality of modules 3 in which drive and support devices 4 are arranged . The vehicle is guided into a track beam 5 which surrounds modules 3 and suspensions 2 in a C-shape. The drive and support device 4 has a linear motor and a part of the support device. The linear motor here is a short stator linear motor with an iron core 6 and a reaction rail 7 . A winding 8 is embedded in the iron core 6 . The linear motor is surrounded by a U-shaped yoke 9 with a coil 10 connected thereto and a U-shaped reaction rail 11 . Two reaction rails 7 and 11 are fixed on the rail beam 5 . The iron core 6 , the winding 8 as well as the yoke 9 and the coil 10 are located on the vehicle or on the drive and support device 4 . The support device is used to attract the reaction rail 11 through the yoke 9 to make the vehicle in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com