Method and apparatus for measuring a circumferential toothing contour of a toothed revolving object

A technology of tooth profile and tooth profile, applied in the field of circumferential tooth profile of internal or external teeth, which can solve the problems of high price and long operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Based on the above introductory description, including the above brief description of the drawings, and based on the above reference numerals used in the figures, the Figure 1 to Figure 9 The examples are mostly self-explanatory. Meanwhile, the following additional explanations are given.

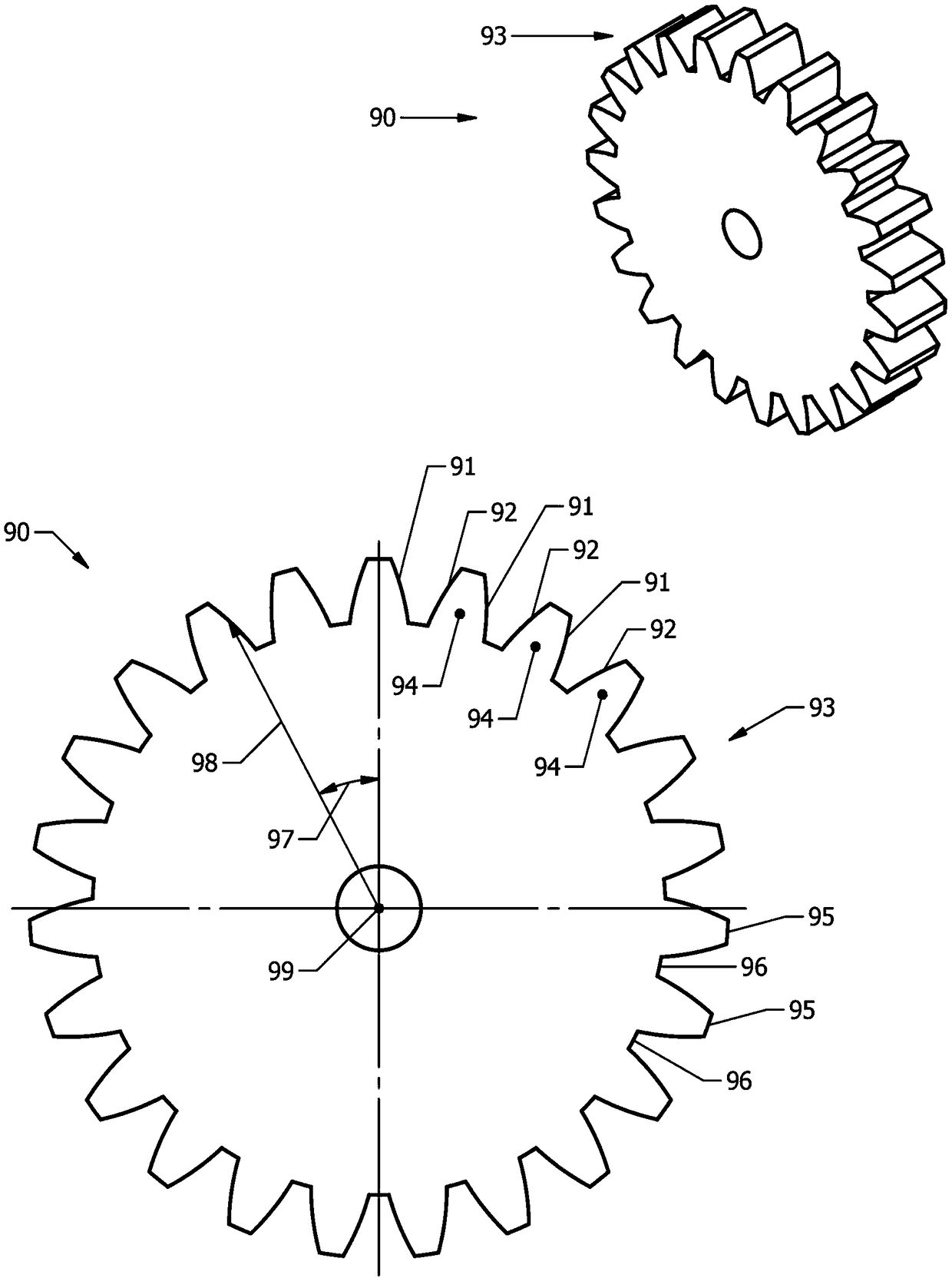

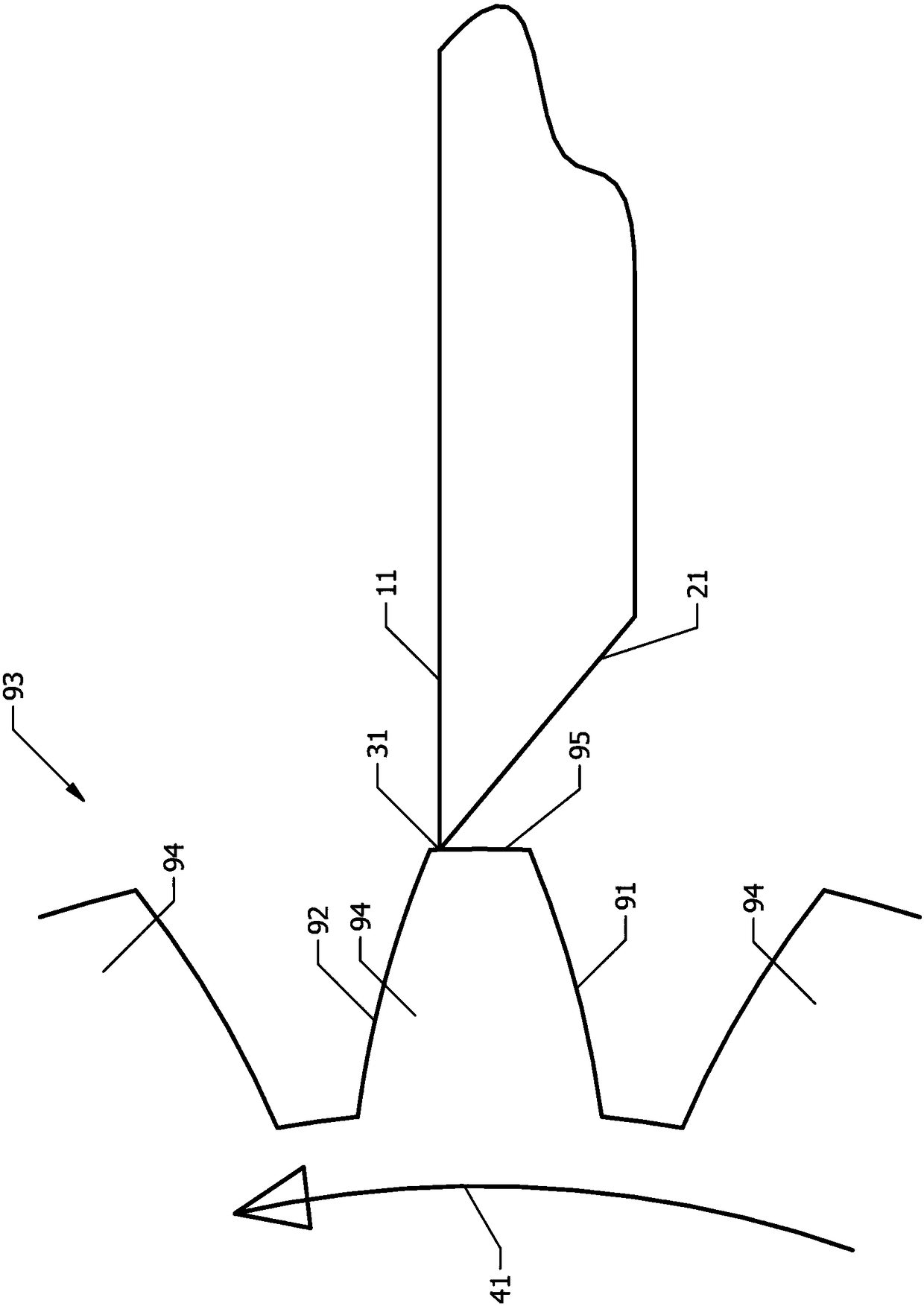

[0091] Such as figure 1 As shown, circumferential tooth profile 93 may be described by radius 98 as a function of angle 97 , where radius 98 and angle 97 are parameters of a polar coordinate system relative to central axis of rotation 99 . Such as figure 1 As shown, the top of a tooth 94 is indicated by reference numeral 95 , while the bottom of the groove between two adjacent teeth 94 is indicated by reference numeral 96 .

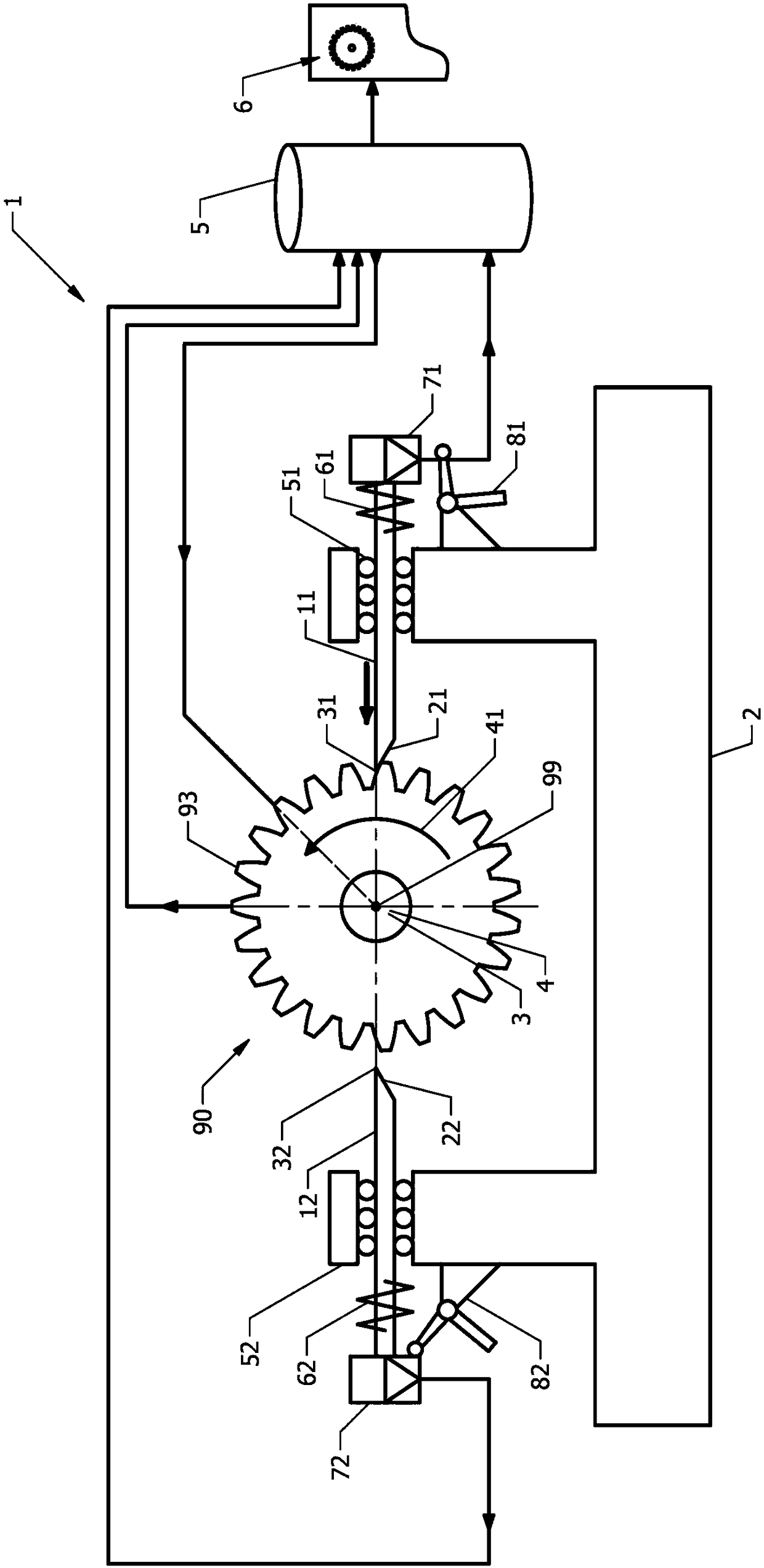

[0092] figure 2 A device 1 is shown in which the holding structure 3 holds a toothed rotating body 90 and in which the drive structure 4 is able to rotate the toothed rotating body 90 about a central axis of rotation 99 . Such as figure 2 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com