A kind of multifunctional rubber composite material containing bacterial cellulose and preparation method thereof

A technology of bacterial cellulose and composite materials, which is applied in the field of preparation of functional rubber, can solve the problems of difficulty in realizing industrialization and high cost, and achieve the effect of realizing water-responsive functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

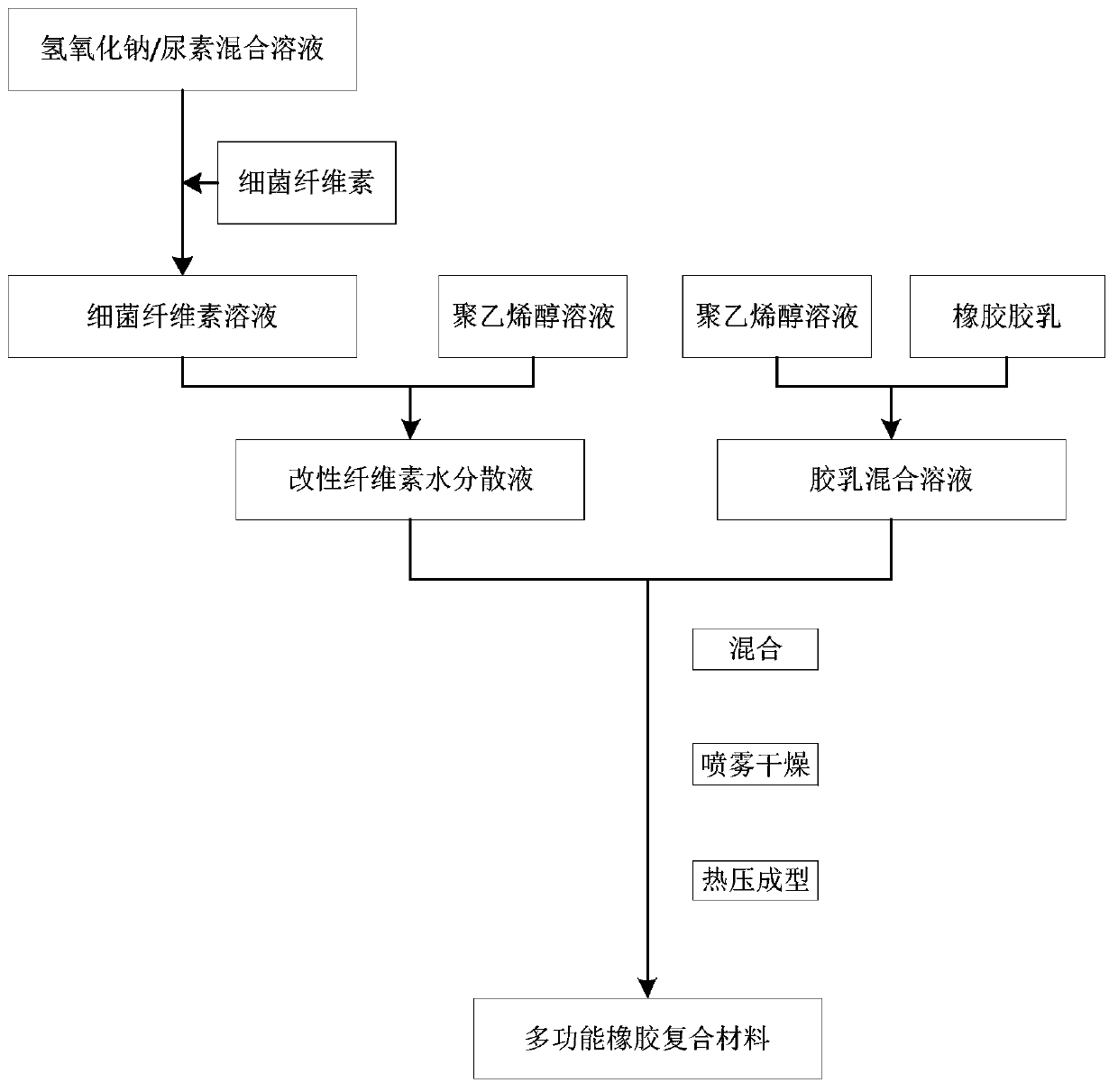

[0026] Such as figure 1 , the preparation method of the multifunctional rubber composite material containing bacterial cellulose of the present invention, comprises the following steps:

[0027] Step 1: Prepare 300mL of 5-10wt% sodium hydroxide / 7-15wt% urea mixed solution, add 30-70 parts of bacterial cellulose with a size of 1000-2000 mesh, and 500-1000W ultrasonic for 0.5-1h to obtain bacterial cellulose solution;

[0028] Step 2: Add 5-20 parts by mass of polyvinyl alcohol with a molecular weight of 5000-10000 and an alcoholysis degree of 90-98% into 500 mL of deionized water, heat to 95° C., and stir for 1-3 hours to obtain a polyvinyl alcohol solution. Adding the bacterial cellulose solution obtained in step 1 dropwise into the polyvinyl alcohol solution, and ultrasonicating at 500-1000W for 0.5-1h to obtain a polyvinyl alcohol-modified bacterial cellulose aqueous dispersion;

[0029] Step 3: Add 25-45 parts by mass of polyvinyl alcohol into 500 mL of deionized water, he...

Embodiment 1

[0042] Step 1: Prepare 300 mL of 5wt% sodium hydroxide / 15wt% urea mixed solution, add 30 parts by mass of bacterial cellulose with a size of 2000 mesh, and 500W ultrasonic for 1 hour to obtain bacterial cellulose solution;

[0043] Step 2: Add 5 parts by mass of polyvinyl alcohol with a molecular weight of 10,000 and a degree of alcoholysis of 90% to 500 mL of deionized water, heat to 95° C., and stir for 1 hour to obtain a polyvinyl alcohol solution. The bacterial cellulose obtained in step 1 The solution is added dropwise into the polyvinyl alcohol solution, and 500W ultrasonic is used for 1 hour to obtain the polyvinyl alcohol modified bacterial cellulose aqueous dispersion;

[0044] Step 3: Add 25 parts by mass of polyvinyl alcohol into 500 mL of deionized water, heat to 95°C, and stir for 1 hour to obtain a polyvinyl alcohol solution, which is mixed with rubber latex. The rubber latex is styrene-butadiene rubber, and the corresponding amount of dry glue is 100 parts by ma...

Embodiment 2

[0047] Step 1: Prepare 300 mL of 5wt% sodium hydroxide / 15wt% urea mixed solution, add 30 parts by mass of bacterial cellulose with a size of 2000 mesh, and 500W ultrasonic for 1 hour to obtain bacterial cellulose solution;

[0048]Step 2: Add 5 parts by mass of polyvinyl alcohol with a molecular weight of 10,000 and a degree of alcoholysis of 90% to 500 mL of deionized water, heat to 95° C., and stir for 2 hours to obtain a polyvinyl alcohol solution. The bacterial cellulose obtained in step 1 The solution is added dropwise into the polyvinyl alcohol solution, and 500W ultrasonic is used for 1 hour to obtain the polyvinyl alcohol modified bacterial cellulose aqueous dispersion;

[0049] Step 3: Add 45 parts by mass of polyvinyl alcohol to 500 mL of deionized water, heat to 95°C, and stir for 1 hour to obtain a polyvinyl alcohol solution, which is mixed with rubber latex. The rubber latex is natural rubber, and the corresponding amount of dry glue is 100 Parts by mass, ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com