Multi-evaporator loop heat pipe

A loop heat pipe and evaporator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems affecting the integrated layout of the load system, not satisfying the coupling of complex heat sources, and the single shape of the evaporator, so as to improve the symmetrical design , Improve integration and expand application flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the accompanying drawings, the specific implementation manners of the present invention will be described in detail below.

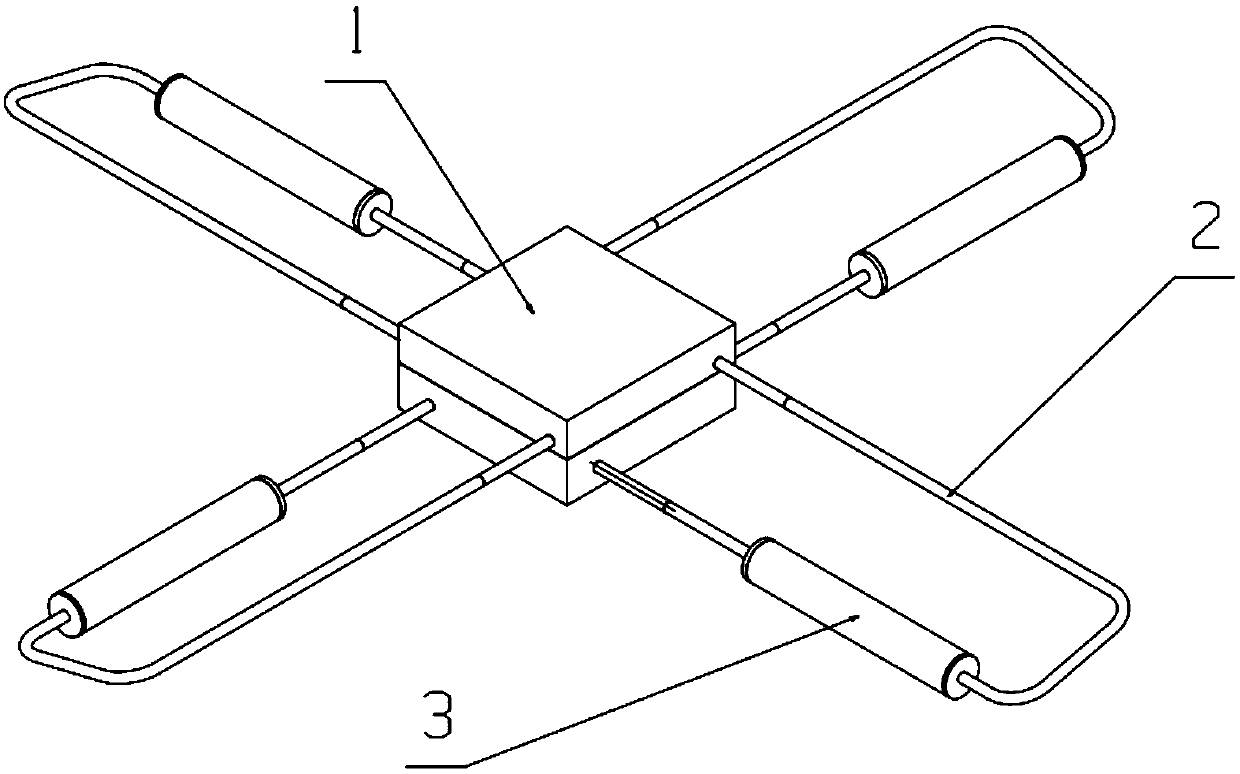

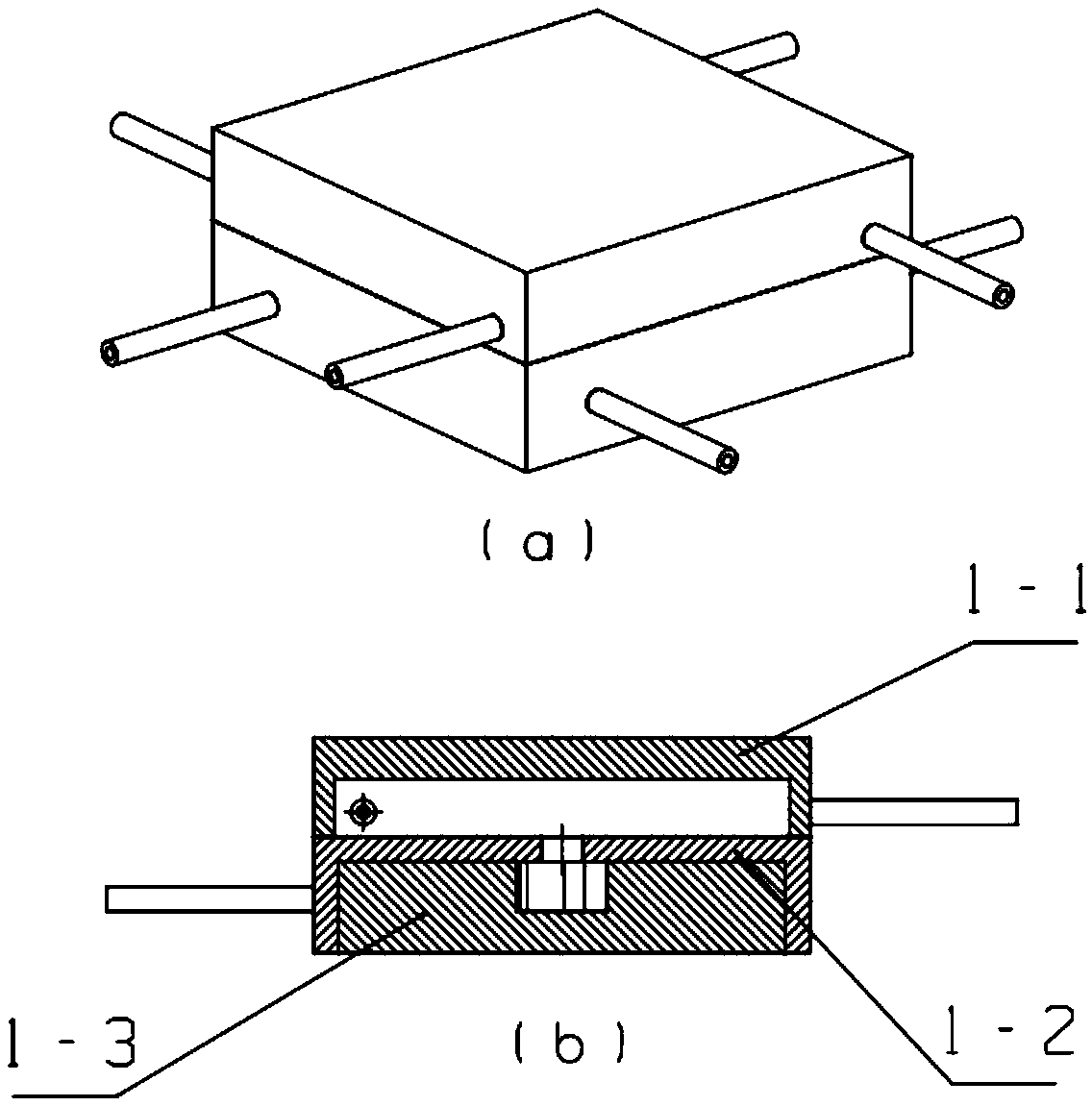

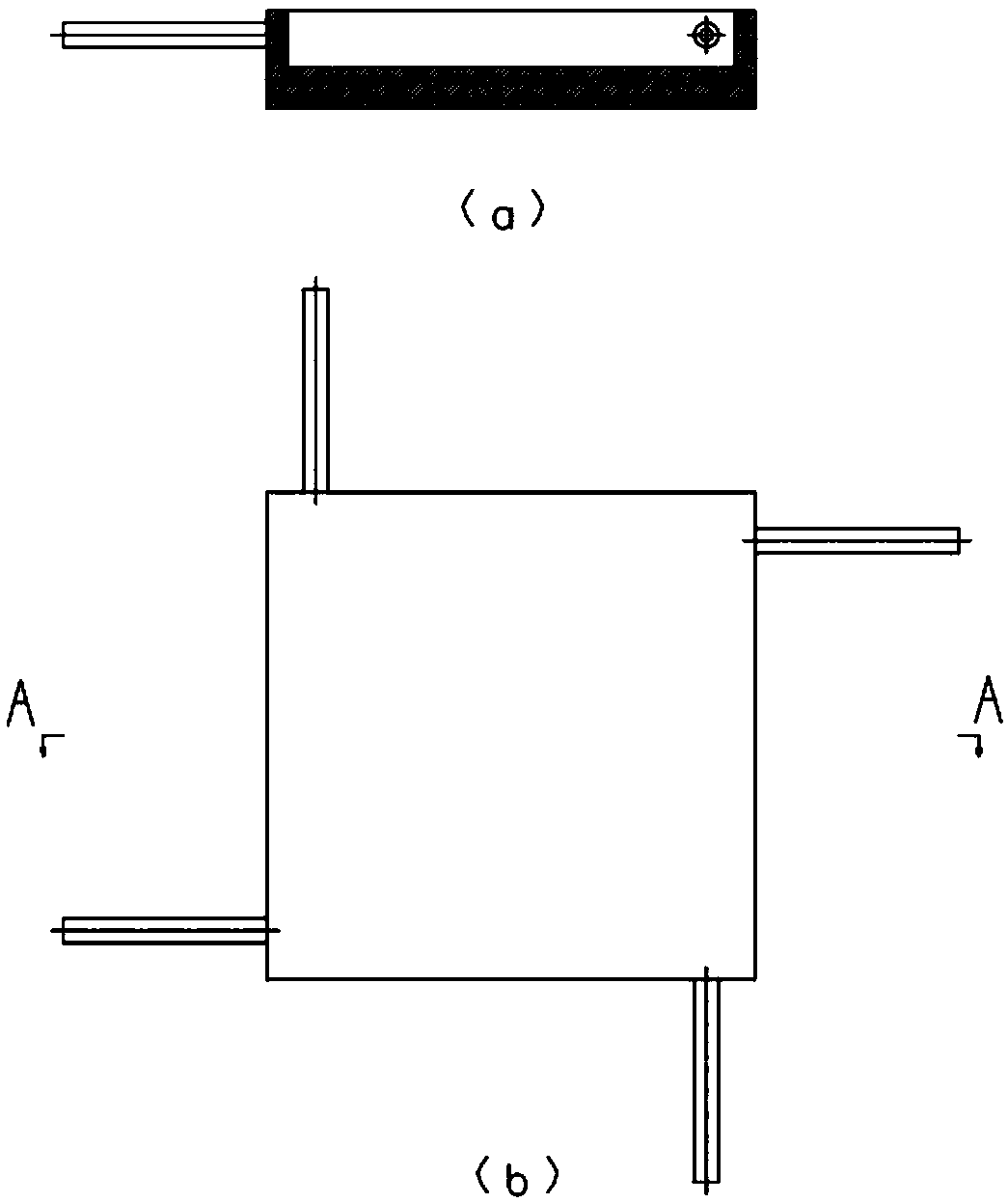

[0023] The structure of the novel multi-evaporator circuit heat pipe machine described in the present invention is as attached figure 1 As shown, it consists of three parts: a condenser (including a steam chamber 1-1, a confluence hole cover plate 1-2, and a condensation distribution plate 1-3), a gas-liquid pipeline 2, and an evaporator compensator unit 3. Among them, the condenser has a special layered design, which is composed of three components: the steam chamber 1-1, the confluence hole cover plate 1-2, and the condensation distribution plate 1-3. The evaporators 3 are located in four different directions of the condenser, and are distributed in a rotationally symmetrical manner around the periphery. The pipeline distribution method and working medium coupling method of the invention can be applied to multi-evaporator cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com