A slag fine grinding system

A fine powder and slag technology, applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of restricting the increase of slag content, large average particle size of slag, and low fine powder content, etc. A number of performance improvements and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

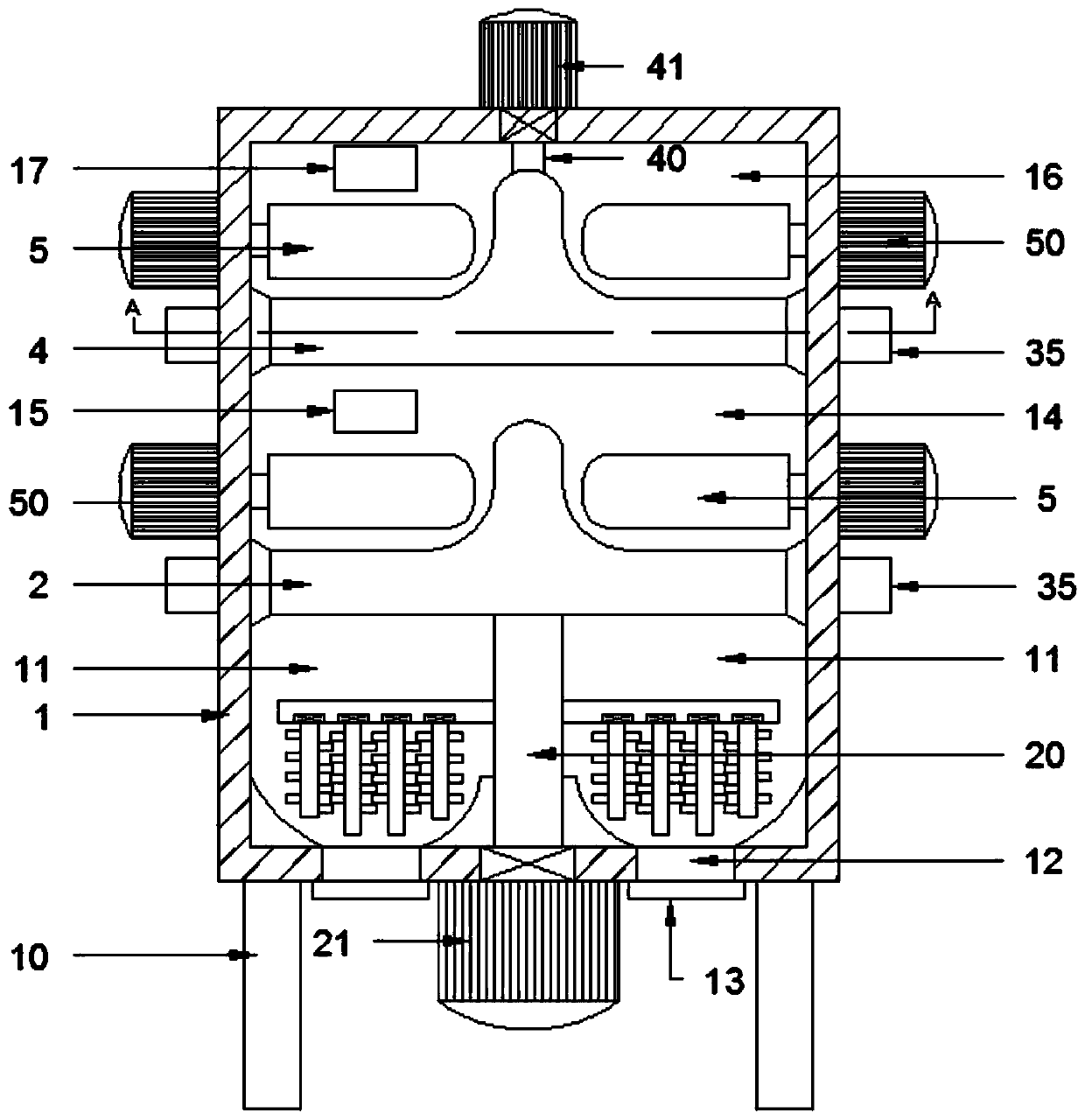

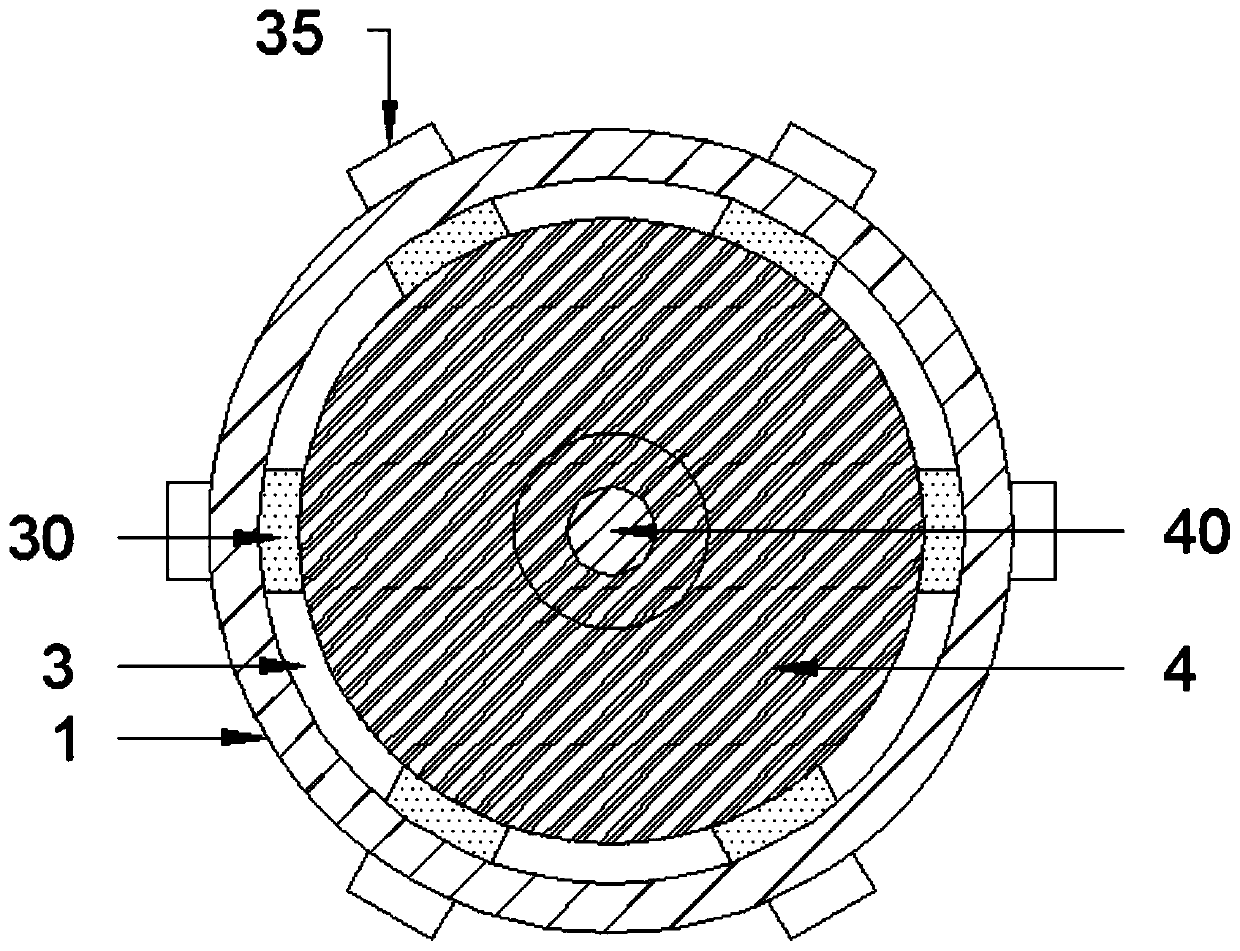

[0023] see Figure 1~5 , in an embodiment of the present invention, a slag fine grinding system includes a grinding box 1, the bottom of the grinding box 1 is supported on the ground by a plurality of support columns 10, and the inside of the grinding box 1 is from top to The clinker grinding table 4 and the slag grinding table 2 are provided in sequence at the bottom, and the clinker grinding table 4 and the slag grinding table 2 divide the inside of the grinding box 1 from top to bottom into a cement clinker rolling chamber 16, a slag rolling chamber 14 and a stirring chamber. chamber 11, the rear panels of the slag rolling chamber 14 and the cement clinker rolling chamber 16 are respectively provided with a slag feed port 15 and a clinker feed port 17, and the inner bottom of the mixing chamber 11 is provided with a plurality of A stirring discharge port 12 for discharging, a material valve cover 13 is installed on the outer opening of the stirring discharge port 12, the cl...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] A frustum-shaped coupling rotating base 22 is fixed around the bottom rod wall of the interlocking rotating shaft 20 , and a downwardly inclined material guide slope 26 is fixed around the bottom surface of the mixing chamber 11 .

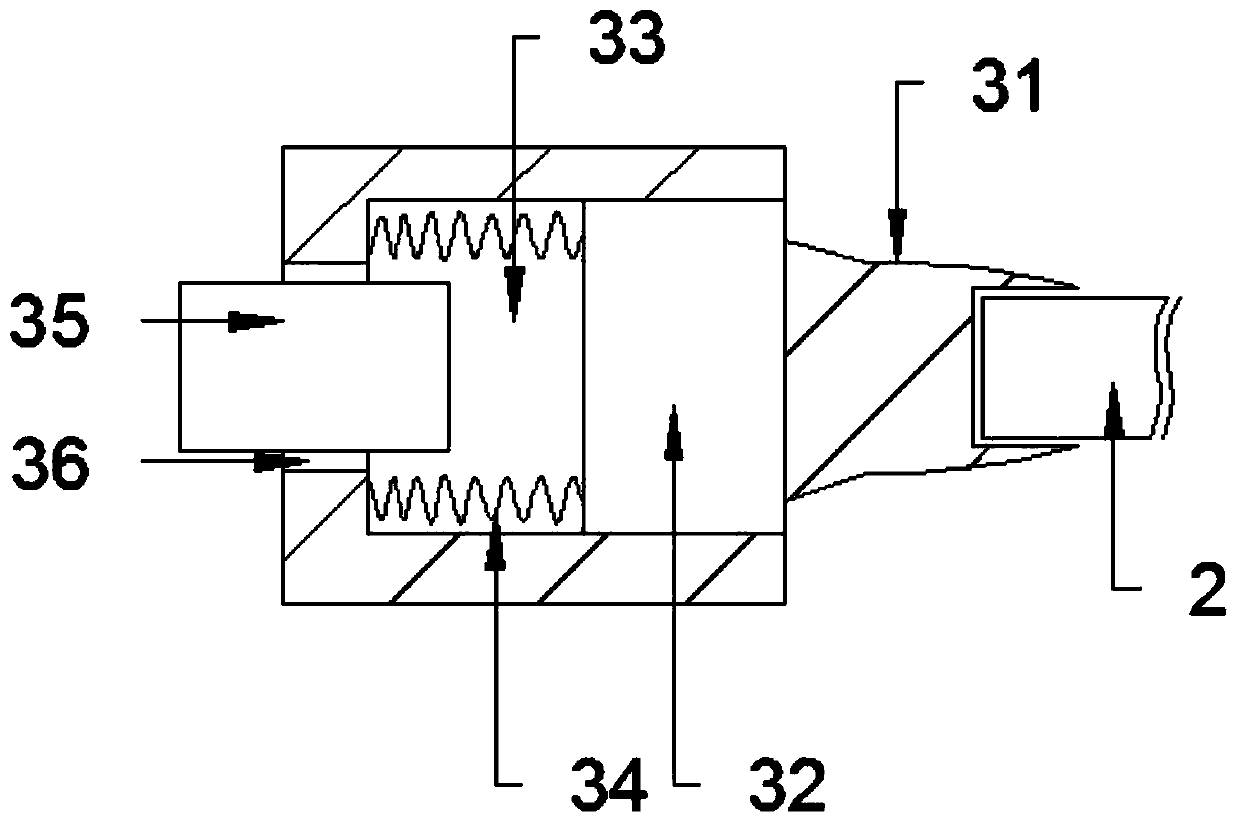

[0031] The electromagnetic opening and closing mechanism includes a plugging plate 31, a telescopic block 32, a telescopic groove 33, a telescopic spring 34 and an electromagnet (35). The side wall of the clinker grinding plate 4 is clamped and sealed with each other. The outer end of the blocking insert 31 is fixed on the telescopic block 32, and the telescopic block 32 slides and is stuck in the telescopic groove 33. In the inside of the left and right side walls of the grinding box 1, the telescopic block 32 and the inner wall of the telescopic groove 33 are laterally fixed with a plurality of telescopic springs 34 with elastic force toward the inside of the mixing chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com