An adjustable raw material mill powder selection system

A raw mill and adjustable technology, applied in the field of grinding, can solve the problems of changing the particle size of the material, reducing the practicability of the raw mill, and lowering the production efficiency of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

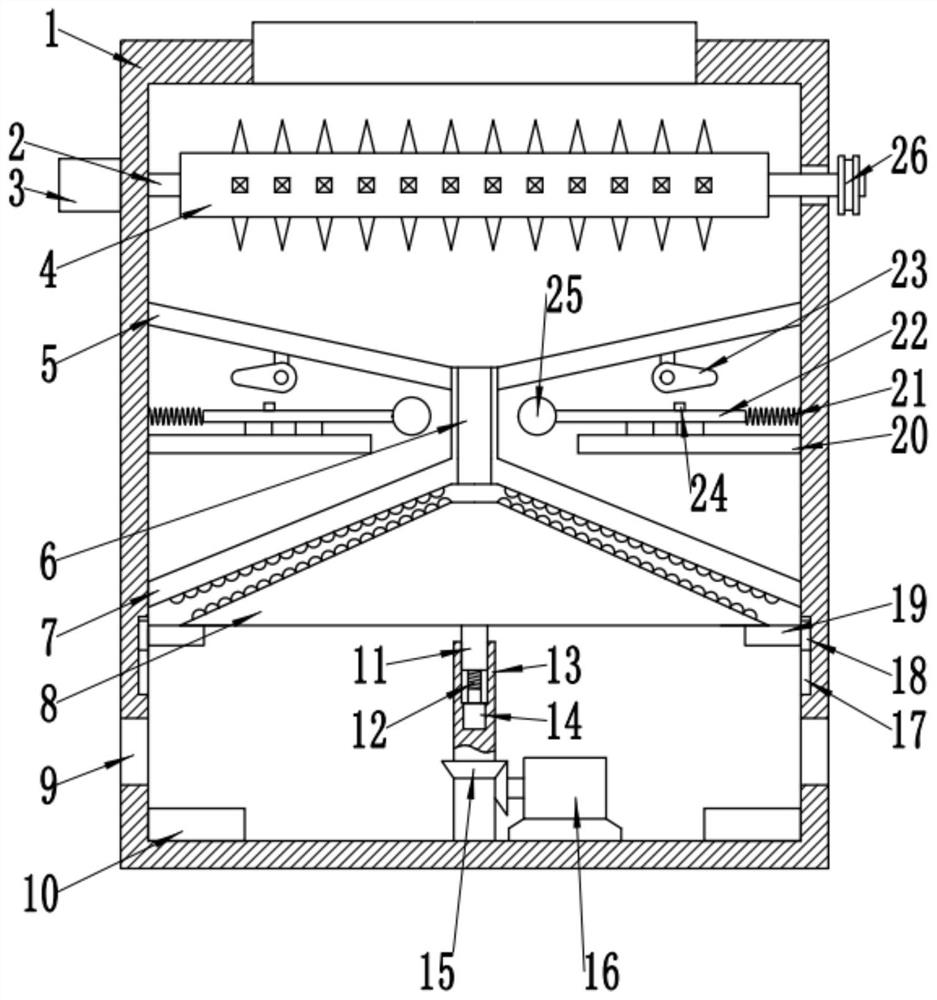

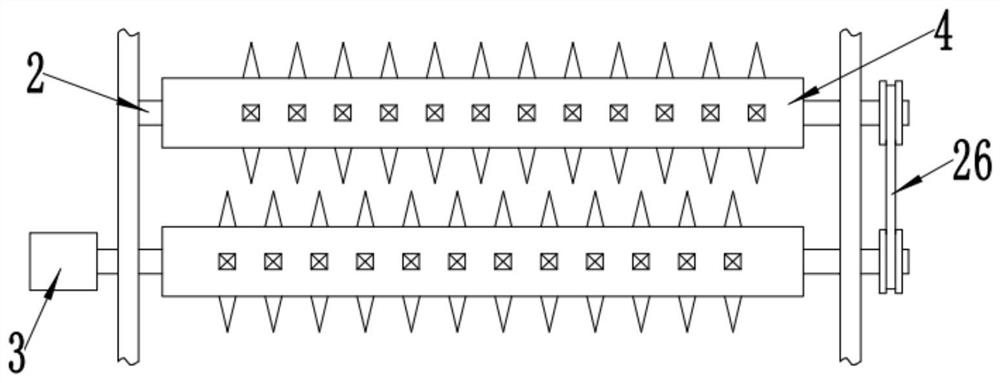

[0024] see Figure 1-2 , an adjustable raw material mill powder selection system, including a body 1, the body 1 is a hollow box structure, the top of the body 1 is provided with a feed port for the addition of materials; the upper part of the body 1 is set There are first rotating shafts 2, and there are two first rotating shafts 2, and they are installed on the front and rear sides of the body 1 for symmetrical rotation. to rotate; the first rotating shaft 2 is fixedly equipped with a crushing roller 4, and the outside of the body 1 is also fixedly installed with a first motor 3, and the output end of the first motor 3 is fixedly connected with one of the first rotating shafts 2, and the first The motor 3 drives one of the first rotating shafts 2 to rotate, and then drives the two first rotating shafts 2 to rotate in the same direction at the same time, so that the crushing roller 4 crushes the materials added to the body 1;

[0025] The inside of the body 1 is located on t...

Embodiment 2

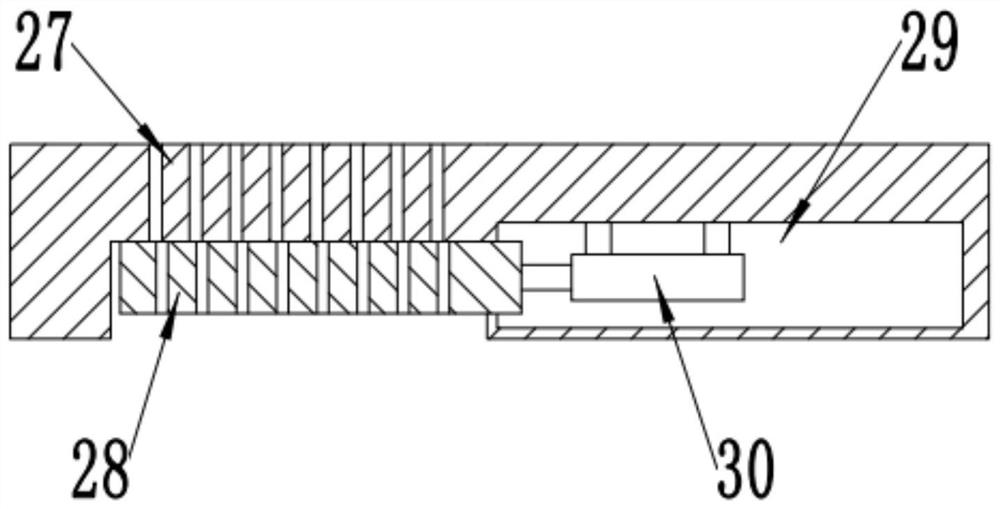

[0029] see Figure 1-3 , an adjustable raw material mill powder selection system, including a body 1, the body 1 is a hollow box structure, the top of the body 1 is provided with a feed port for the addition of materials; the upper part of the body 1 is set There are first rotating shafts 2, and there are two first rotating shafts 2, and they are installed on the front and rear sides of the body 1 for symmetrical rotation. to rotate; the first rotating shaft 2 is fixedly equipped with a crushing roller 4, and the outside of the body 1 is also fixedly installed with a first motor 3, and the output end of the first motor 3 is fixedly connected with one of the first rotating shafts 2, and the first The motor 3 drives one of the first rotating shafts 2 to rotate, and then drives the two first rotating shafts 2 to rotate in the same direction at the same time, so that the crushing roller 4 crushes the materials added to the body 1;

[0030] The inside of the body 1 is located on t...

Embodiment 3

[0036] see Figure 1-3 , an adjustable raw material mill powder selection system, including a body 1, the body 1 is a hollow box structure, the top of the body 1 is provided with a feed port for the addition of materials; the upper part of the body 1 is set There are first rotating shafts 2, and there are two first rotating shafts 2, and they are installed on the front and rear sides of the body 1 for symmetrical rotation. to rotate; the first rotating shaft 2 is fixedly equipped with a crushing roller 4, and the outside of the body 1 is also fixedly installed with a first motor 3, and the output end of the first motor 3 is fixedly connected with one of the first rotating shafts 2, and the first The motor 3 drives one of the first rotating shafts 2 to rotate, and then drives the two first rotating shafts 2 to rotate in the same direction at the same time, so that the crushing roller 4 crushes the materials added to the body 1;

[0037] The inside of the body 1 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com