Method for determining lubricating grease content of motor bearing by using BP neural network

A BP neural network, motor bearing technology, applied in the direction of neural learning method, biological neural network model, neural architecture, etc., to achieve the convenient effect of the method of grease content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments. The present embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

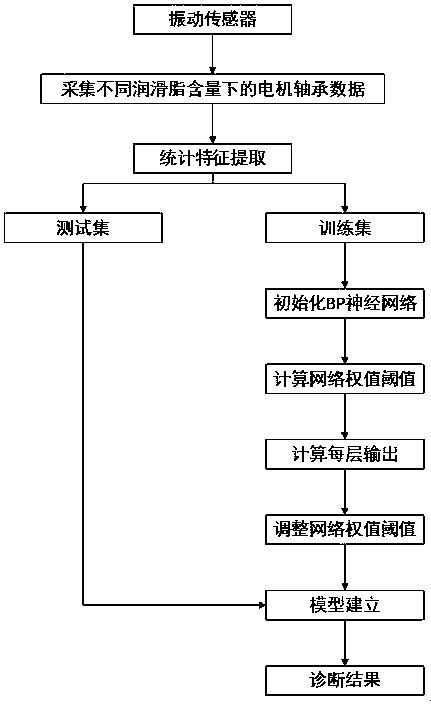

[0034] according to figure 1 , 2 As shown, this embodiment provides a method for determining the grease content of a motor bearing using a BP neural network, which is characterized in that it includes the following steps:

[0035] Step 1: Measurement of hollow volume of motor bearing and selection of grease content

[0036] First, use the water injection method to measure the hollow volume between the motor bearing rollers to be 7ml, and inject 6 different contents of grease into the motor bearing, respectively 0ml, 0.7ml, 1.4ml, 2.1ml, 2.8ml, 3.5ml;

[0037] Step 2: Data collection

[0038] Use the acceleration sensor to collect the vibration data of the motor bearin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap