Cargo separation method, device and computer readable storage medium

A separation method and separation equipment technology, applied in the direction of sorting, transportation and packaging, conveyor objects, etc., can solve the problems of unfavorable space saving, large space occupied by the assembly line, etc., to avoid stacking and passing of goods, occupy less space, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for separating goods, which is used for logistics sorting.

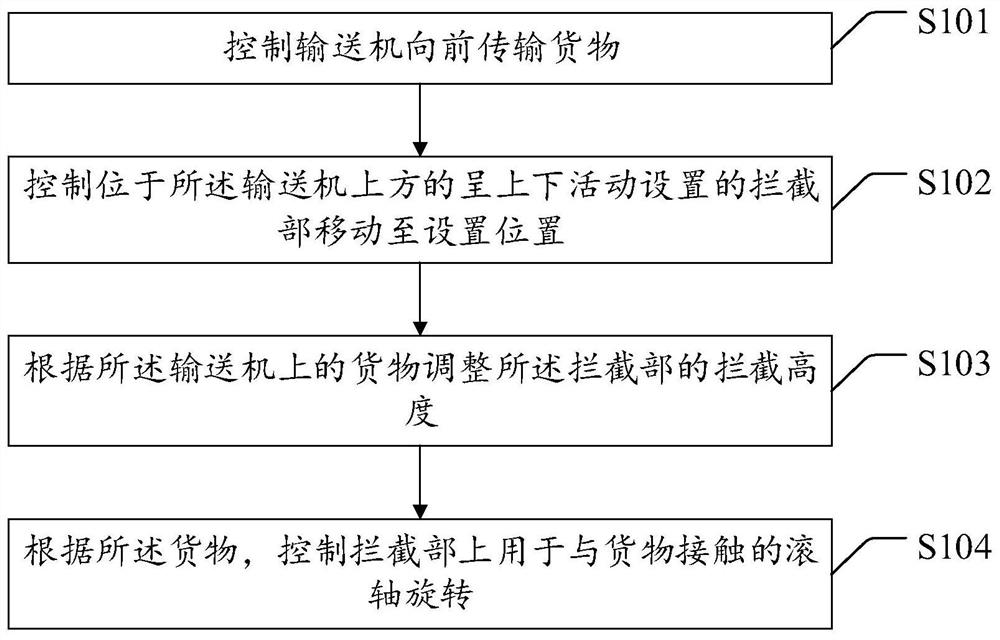

[0044] Please see figure 1 , the cargo separation method includes:

[0045] Step S101, controlling the conveyor to transport the goods forward;

[0046] Step S102, controlling the intercepting part positioned above the conveyor to move up and down to the setting position;

[0047] Step S103, adjusting the intercepting height of the intercepting part according to the goods on the conveyor.

[0048] In this embodiment, the conveyor is firstly controlled to transport the goods forward. Wherein, the conveyor can be in various forms, such as conveyor belt type, roller type, or roller type and the like. When the conveyor is working, it usually conveys the goods continuously at the preset transmission speed, or pauses and conveys the goods intermittently as needed. The goods are usually packed in cartons, plastic bags, or envelopes, etc.

[0049] In this embodiment, after the c...

Embodiment 2

[0063] This embodiment provides a method for separating goods. Based on the above embodiments, the steps are described in more detail, as follows:

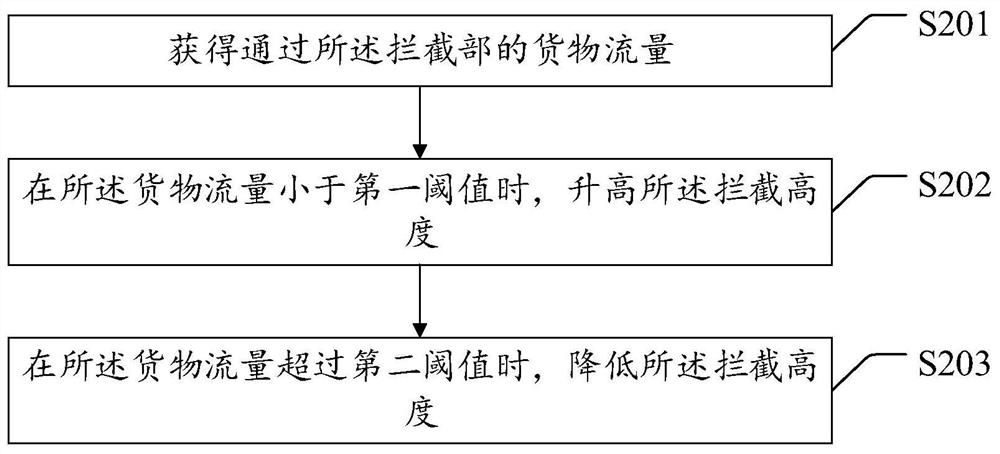

[0064] Please see figure 2 , the adjusting the interception height of the interception part according to the goods on the conveyor includes:

[0065] Step S201, obtaining the flow of goods passing through the interception unit;

[0066] Step S202, when the cargo flow rate is less than a first threshold, raising the interception height;

[0067] Step S203, when the cargo flow exceeds a second threshold, lower the interception height.

[0068] Other steps in this embodiment are the same as those in the foregoing embodiments, and reference may be made to the foregoing embodiments for details, and details are not repeated here.

[0069] In this embodiment, after the rotation of the intercepting portion is controlled, the flow of goods passing through the intercepting portion is obtained. Wherein, the flow of goods may be the flow...

Embodiment 3

[0074] This embodiment provides a method for cargo separation. Based on the above embodiment, the steps are replaced, as follows:

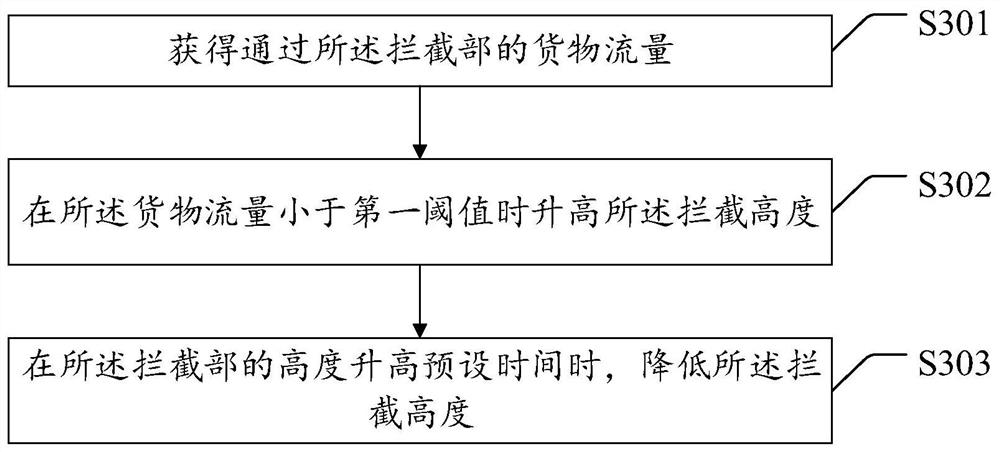

[0075] Please see image 3 , the adjusting the interception height of the interception part according to the goods on the conveyor includes:

[0076] Step S303, lowering the intercepting height when the height of the intercepting part rises for a preset time.

[0077] Other steps in this embodiment are the same as those in the foregoing embodiments, and reference may be made to the foregoing embodiments for details, and details are not repeated here.

[0078] In this embodiment, after the height of the intercepting portion is controlled to rise, the intercepting height is lowered when the height of the intercepting portion rises for a preset time. Wherein, the preset time may be 5 seconds, 10 seconds or more and so on. For example, if the rising speed is 1cm / 5 seconds, the intercepting part will rise by 1cm after the action of raising the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com