Sealing strips and methods of use

A sealing strip, flat technology, applied in packaging and other directions, to achieve the effect of less failure, high efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0210] 1. Sealing strip

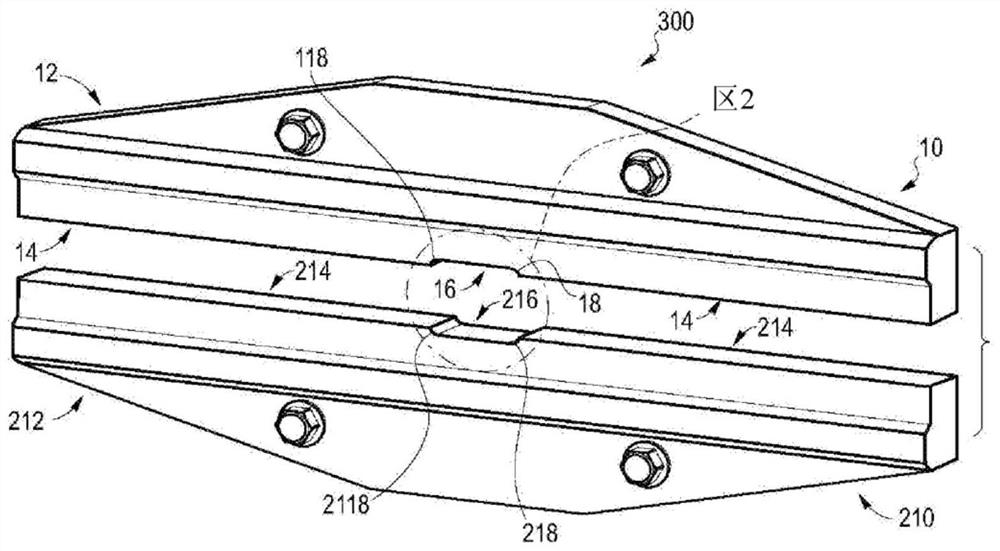

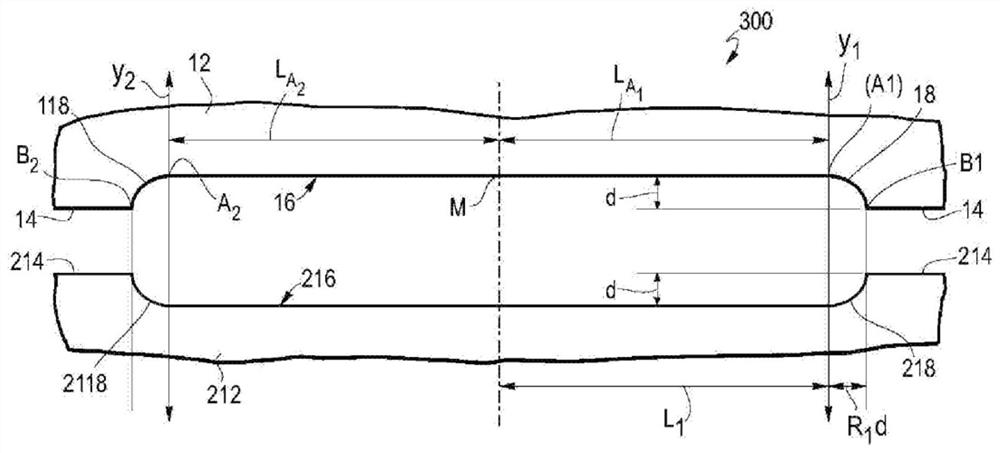

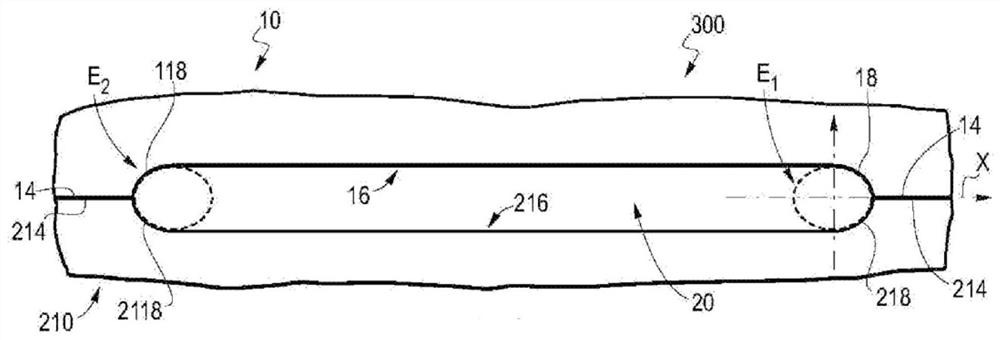

[0211] Flexible pouches are manufactured by heat sealing the fitment to a multilayer film using a seal strip device. The weatherstrip device has an opposed weatherstrip having such Figure 1 to Figure 4 The structure of the sealing strip 10, 210 shown in . Each weather strip satisfies Equation (1) and Equation (2), in which the following values are shown in Table 2 below.

[0212] Table 2

[0213]

[0214] Flexible multilayer films having the structures shown in Table 3 below were used in the inventive examples.

[0215] 2. Multilayer film

[0216] Table 3. Composition of flexible multilayer film (Film 1) laminated multilayer film

[0217]

[0218] 3. Accessories

[0219] Nine comparative samples (CS) and four inventive examples (IE) of fittings were prepared. The dimensions of each fitting are the same, and the only difference between the fittings is the material. CS fittings consist of 100wt% INFUSE 9817. The accessory of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com