Device for testing oil gathering capacity of oil inlet of connecting rod

A technology of capacity testing and oil inlet, which is applied in the direction of measuring devices, engine testing, mechanical parts testing, etc., can solve the problem of no accurate measurement of lubricating oil quantity, and achieve the effect of accurate calculation and input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

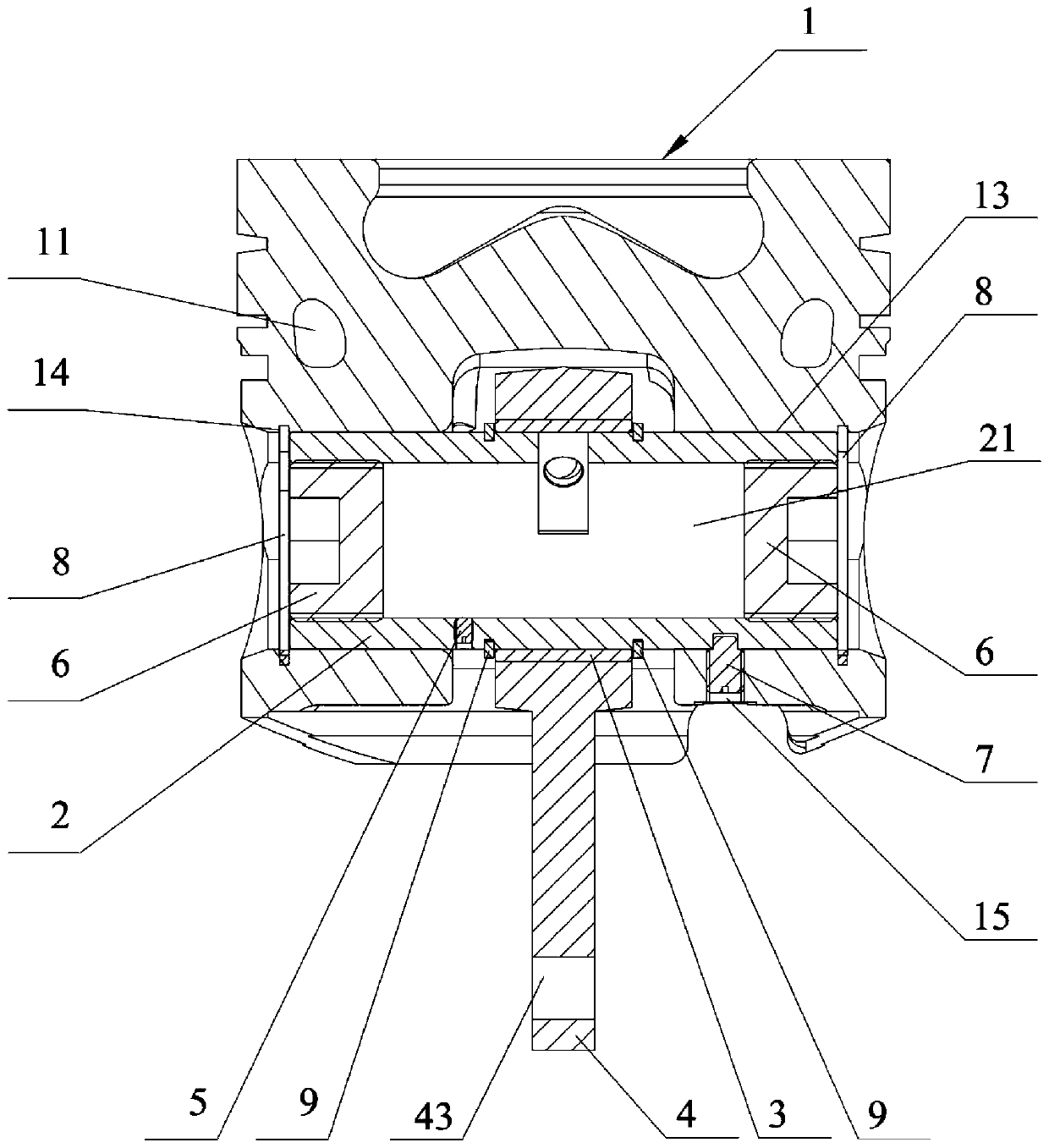

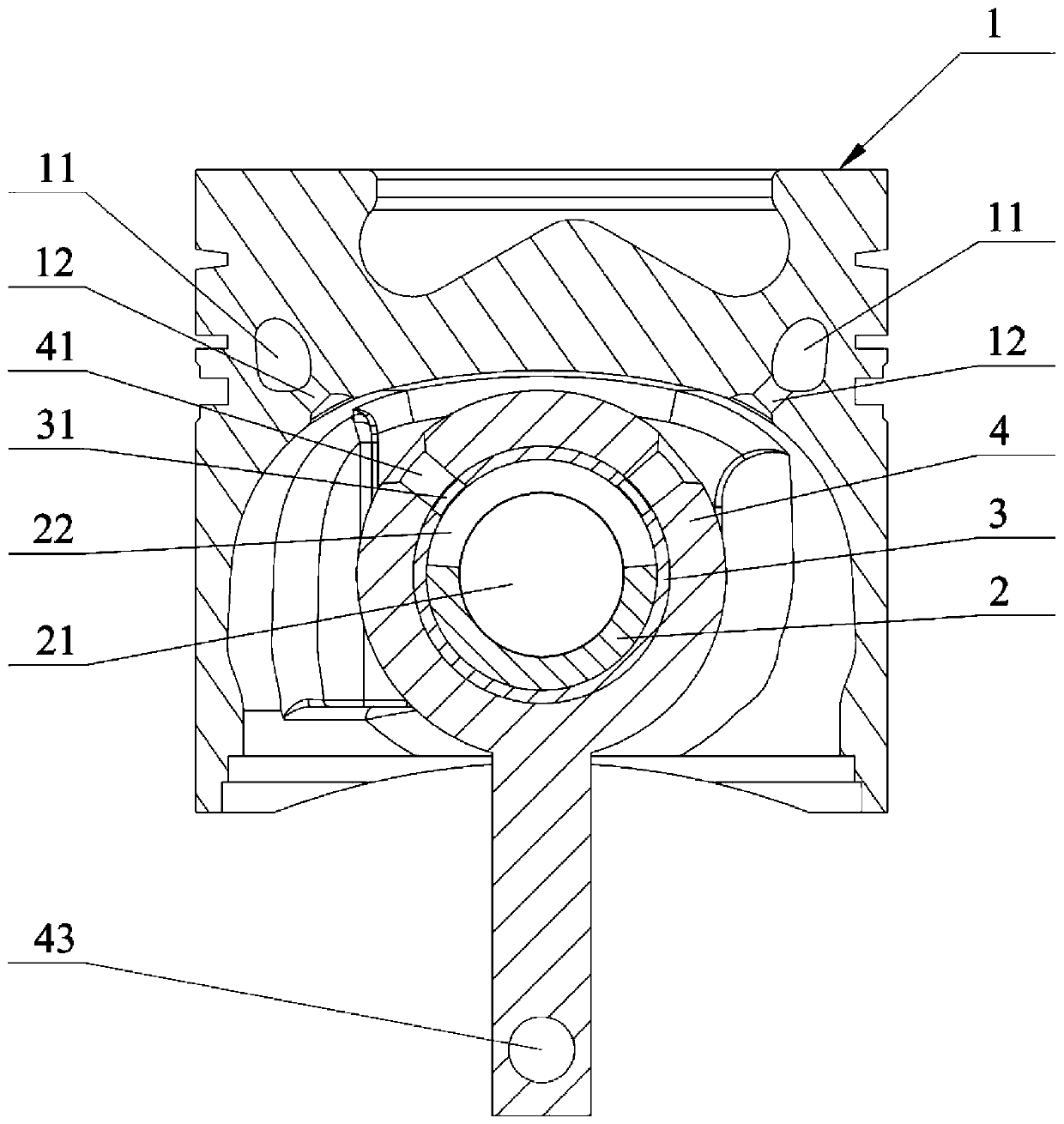

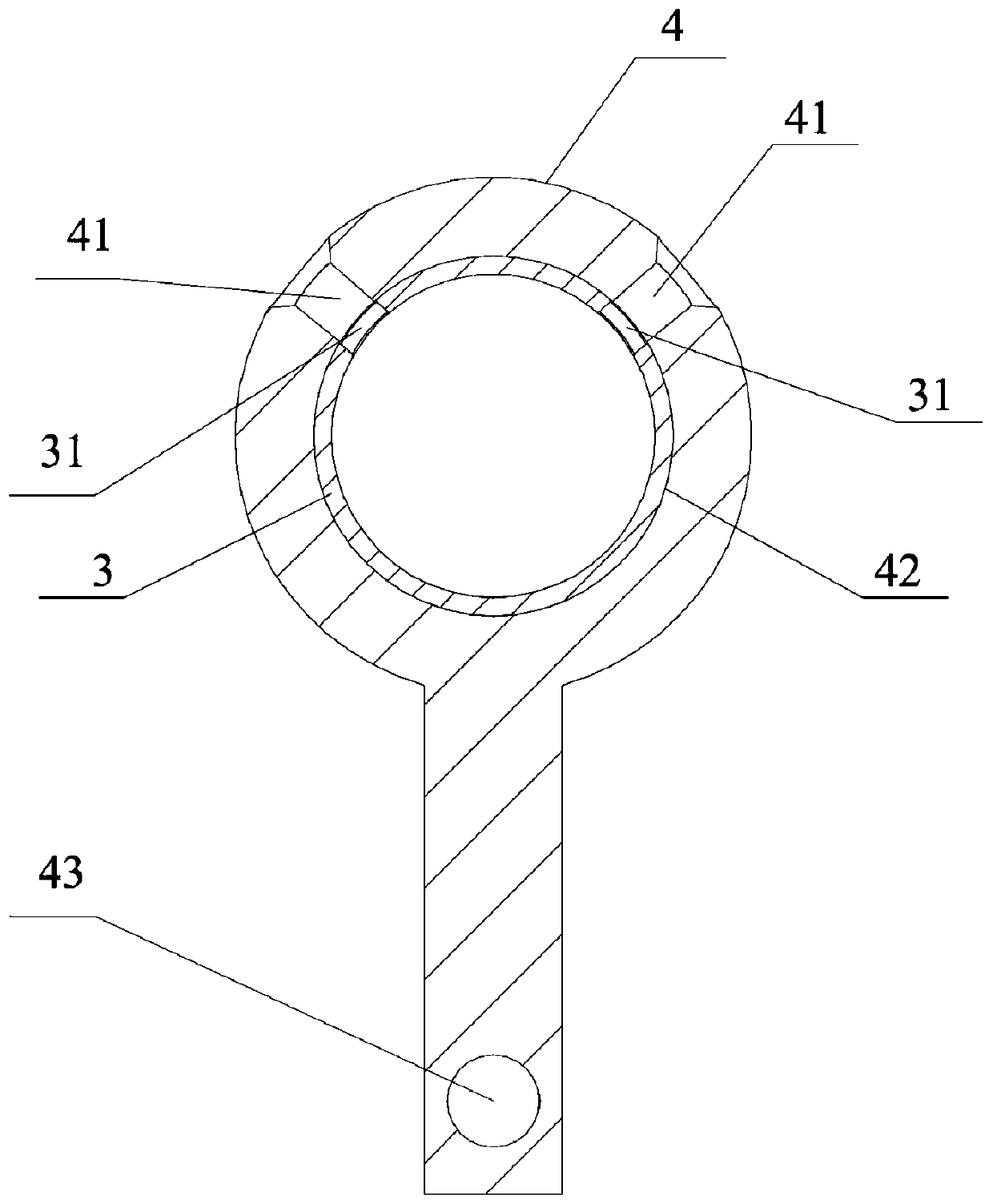

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0039] like Figure 1-6 As shown, this embodiment provides a test device for the oil collection capacity of the connecting rod oil inlet, including a piston 1, a piston pin 2, a connecting rod bushing 3, a simulated connecting rod 4 and a driving device. The piston 1 is provided with internal cooling oil Cavity 11. The piston pin 2 is fixed on the piston 1, and the simulated connecting rod 4 is sleeved on the piston pin 2 through the connecting rod bushing 3. Specifically, the piston pin 2 is provided with an oil storage chamber 21, and is also provided with an oil collection hole 22 and an oil discharge hole 23 communicating with the oil storage chamber 21. The oil discharge hole 23 is provided with a detachable and washable plugging member 5. The rod bushing 3 is rotatably sleeved on the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com