A kind of method for promoting cationic organic molecule intercalation kaolinite

An organic molecule, cationic technology, applied in the field of preparation of kaolinite intercalation complexes, can solve problems such as inability to intercalate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

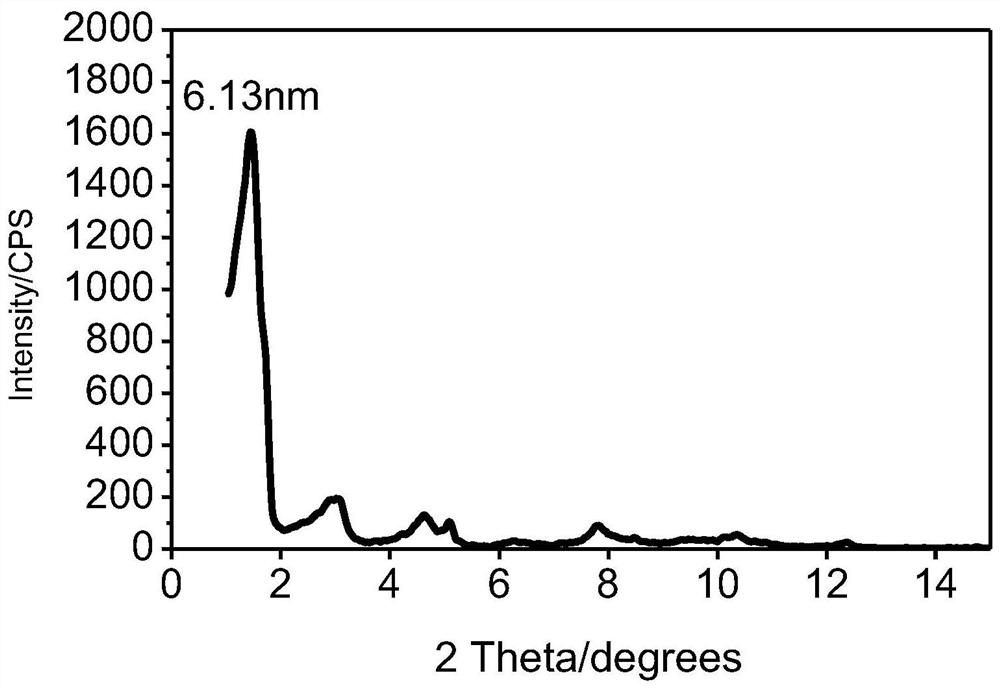

[0045] The methanol / kaolinite interlayer graft compound prepared rapidly by acid catalysis was mixed with 5% dilute hydrochloric acid according to the mass ratio of 1:1, the heating temperature was 70°C and placed in a single-necked flask for heating, and a condensing refluxer was added to the flask mouth, Heating for 60min. The suspension was then centrifuged and washed three times with methanol. During each washing, the mass ratio of the graft complex between the methanol / kaolinite layers to methanol was 2:1, and then centrifuged to obtain the pre-pickled methanol. The XRD measurements of the grafted composites between the kaolinite / kaolinite layers are shown in Table 1. where Fe 2 O 3 , MgO, CaO, Na 2 O, K 2 O, TiO 2 , P 2 O 5 , MnO, ZrO 2 That is, the metal cation impurities adsorbed on the surface of kaolinite. Dissolve cetyltrimethylammonium bromide in methanol at a concentration of 1 mol / L. The pre-pickled methanol / kaolinite interlayer graft complex was mixed ...

Embodiment 2

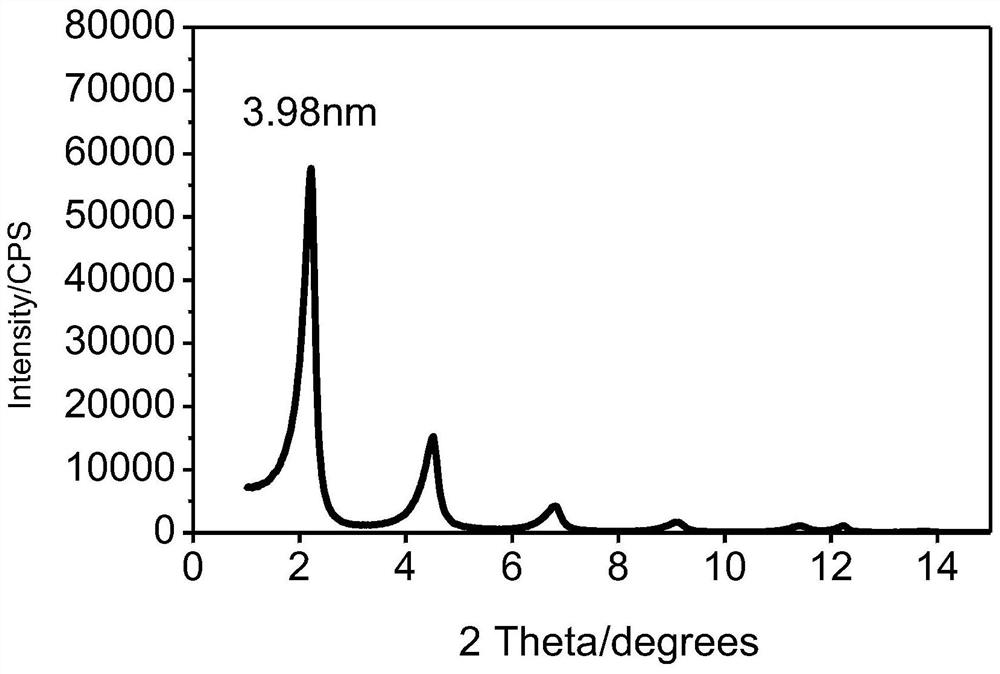

[0047] The methanol / kaolinite interlayer graft compound prepared rapidly by acid catalysis is mixed with 25% dilute sulfuric acid in a mass ratio of 1:3, and the heating temperature is 90 ° C and placed in a single-neck flask for heating, and a condenser reflux device is added to the flask mouth, Heating for 30min. The suspension was then centrifuged and washed three times with methanol. During each washing, the mass ratio of the graft complex between the methanol / kaolinite layers to methanol was 10:1, and then centrifuged to obtain the pre-pickled methanol. The XRD measurements of the grafted composites between the kaolinite / kaolinite layers are shown in Table 1. where Fe 2 O 3 , MgO, CaO, Na 2 O, K 2 O, TiO 2 , P 2 O 5 , MnO, ZrO 2 That is, the metal cation impurities adsorbed on the surface of kaolinite. The octadecylamine was dissolved in methanol at a concentration of 1 mol / L. The pre-pickled methanol / kaolinite interlayer graft complex was mixed with a methanol ...

Embodiment 3

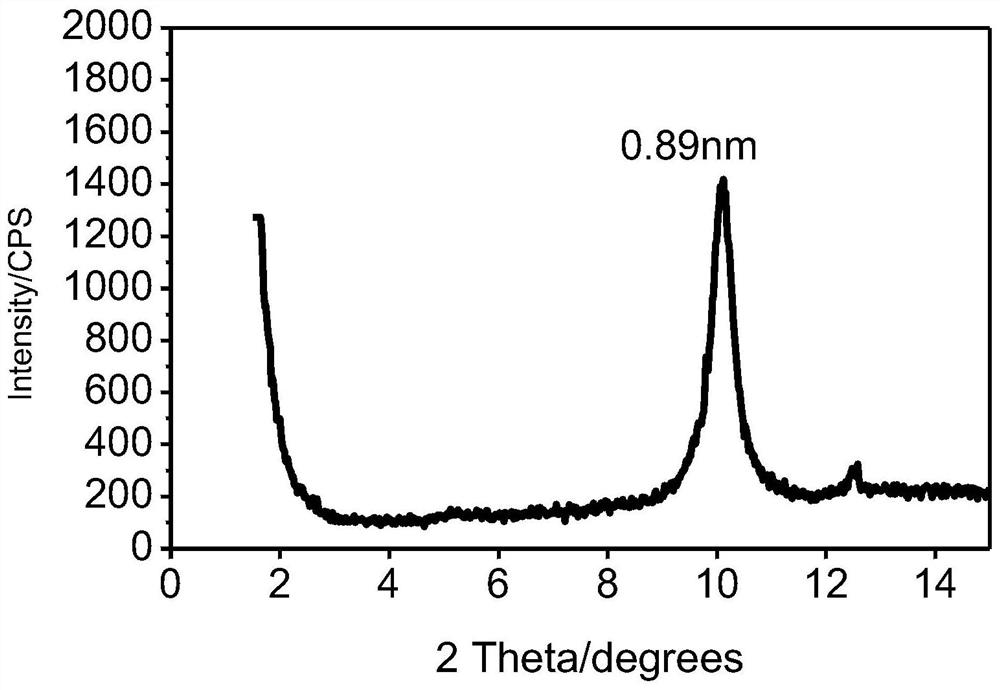

[0049] The methanol / kaolinite interlayer graft compound prepared rapidly by acid catalysis was mixed with 10% dilute hydrochloric acid according to a mass ratio of 1:2, and the heating temperature was 80 °C and placed in a single-necked flask for heating, and a condenser reflux was added to the flask. Heating for 40min. The suspension was then centrifuged and washed three times with methanol. During each washing, the mass ratio of the graft complex between the methanol / kaolinite layers to methanol was 8:1, and then centrifuged to obtain the pre-pickled methanol. / Kaolinite interlayer graft complex. Dissolve cetyltrimethylammonium bromide in methanol at a concentration of 1 mol / L. The pre-pickled methanol / kaolinite interlayer graft complex was mixed with a methanol solution of cetyltrimethylammonium chloride according to a mass ratio of 1:20, and the reaction was carried out for 24 hours. The precipitate was collected by centrifugation, and washed with methanol to remove exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com