Method for monitoring temperature control performance of annealing equipment

An annealing equipment and annealing temperature technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of obtaining changes in working temperature, not being very effective and accurate, and poor uniformity, so as to achieve monitoring uniformity and improve The effect of validity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description.

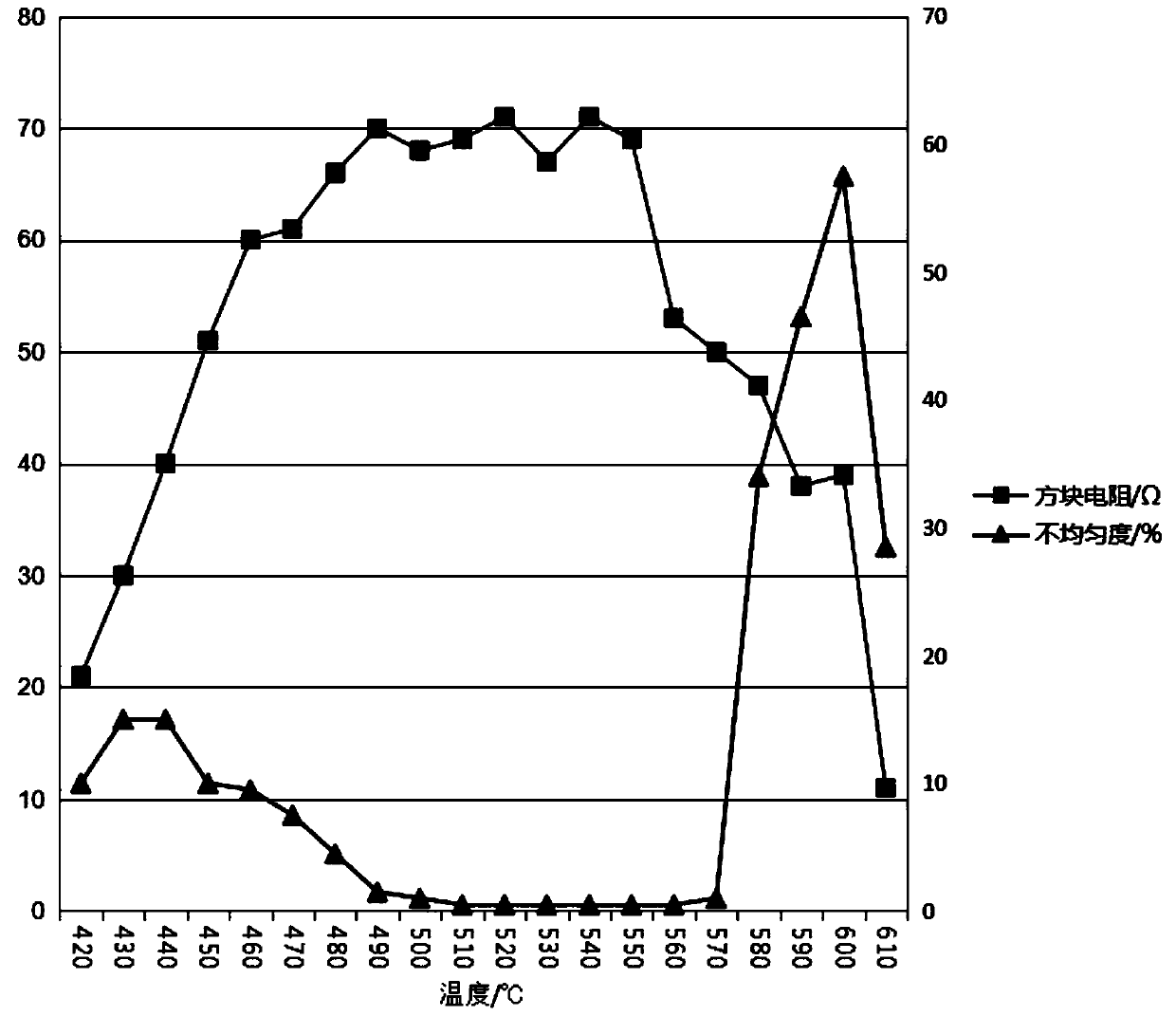

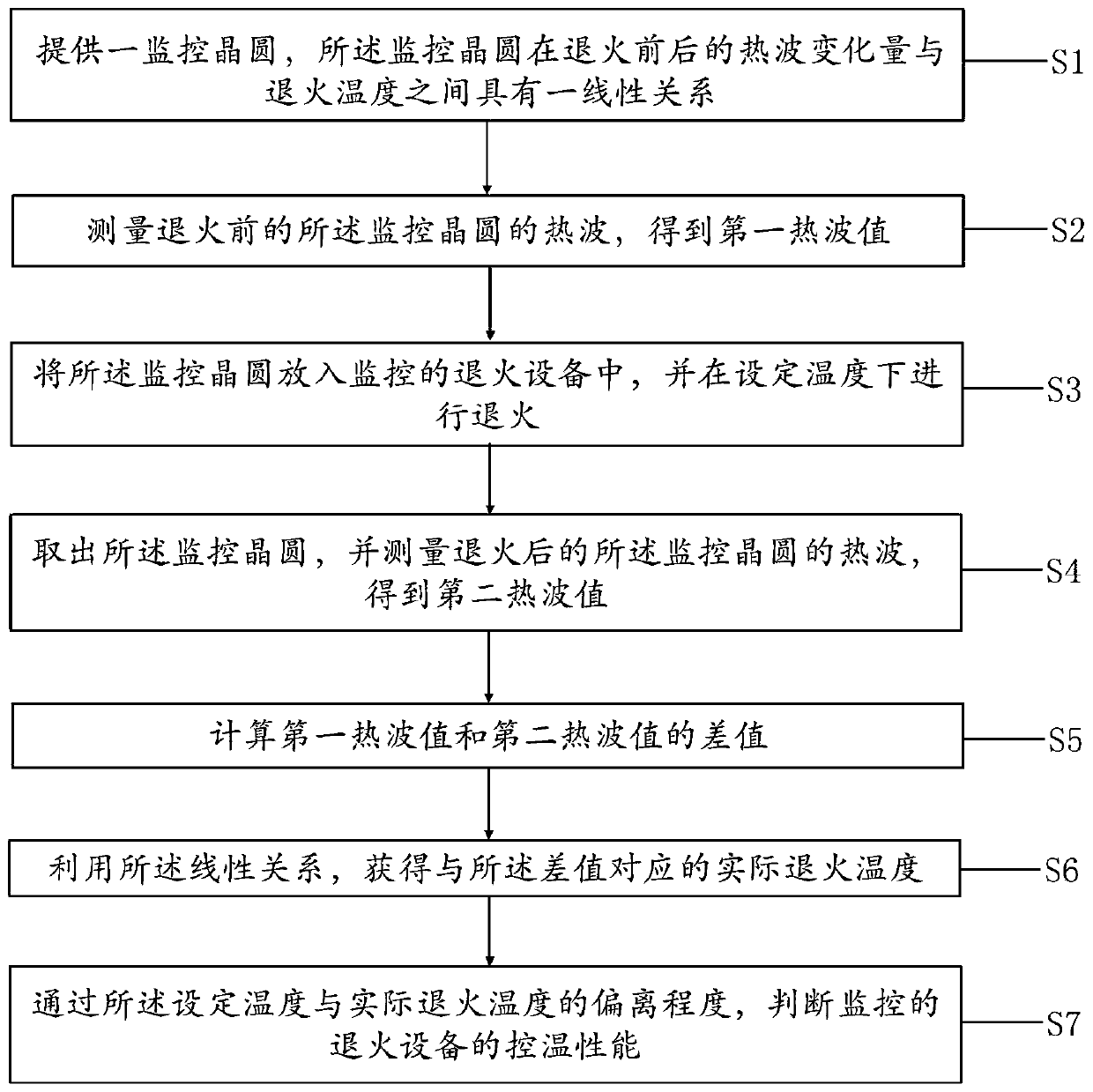

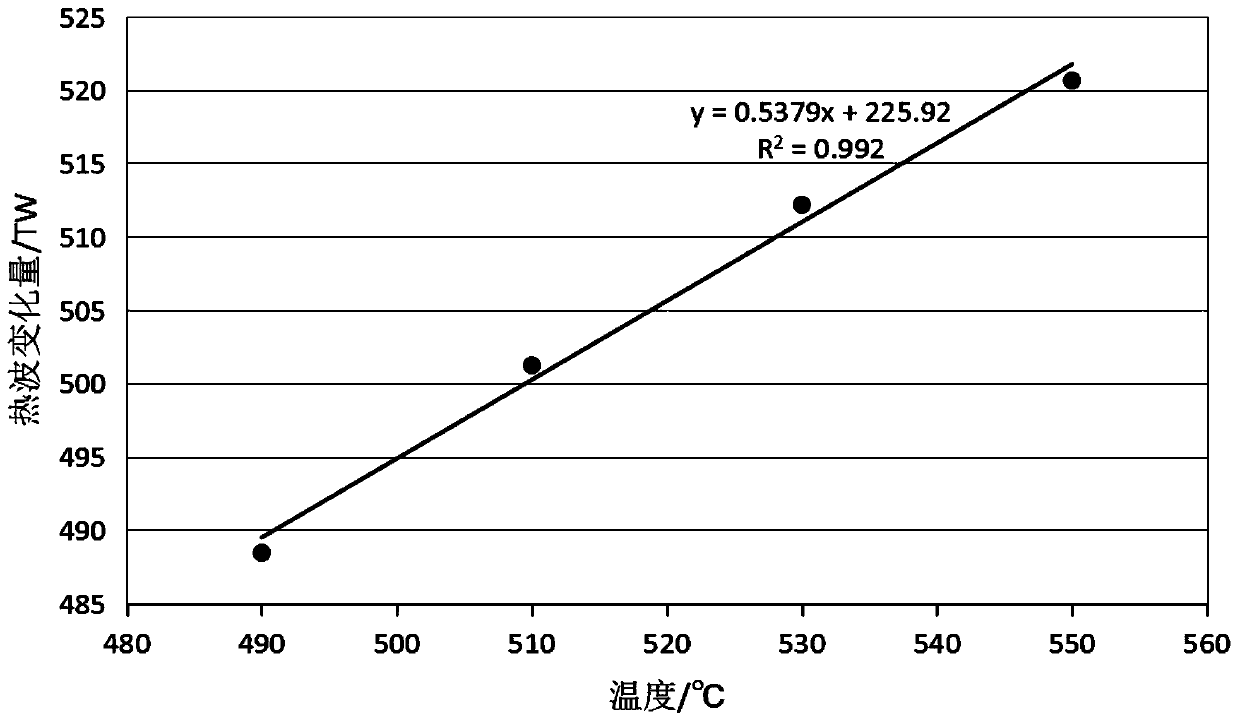

[0030] As mentioned in the background art, the existing monitoring methods cannot obtain effective and accurate results when monitoring the actual working temperature of the rapid annealing equipment. In order to improve the effectiveness and accuracy of monitoring the actual working temperature of the rapid annealing equipment, an embodiment of the present invention provides a method for monitoring the temperature control performance of the annealing equipment. figure 2 It is a schematic flowchart of a method for monitoring the temperature control performance of annealing equipment according to an embodiment of the present invention. like figure 2 As shown, the method for monitoring the temperature control performance of an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap