Connecting structure for metal profile floor

A technology of metal profiles and connection structures, applied in building structures, floors, buildings, etc., can solve problems such as lack of longitudinal connection structures, and achieve the effect of improving floor installation efficiency, improving flexibility, and reducing relative movement margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

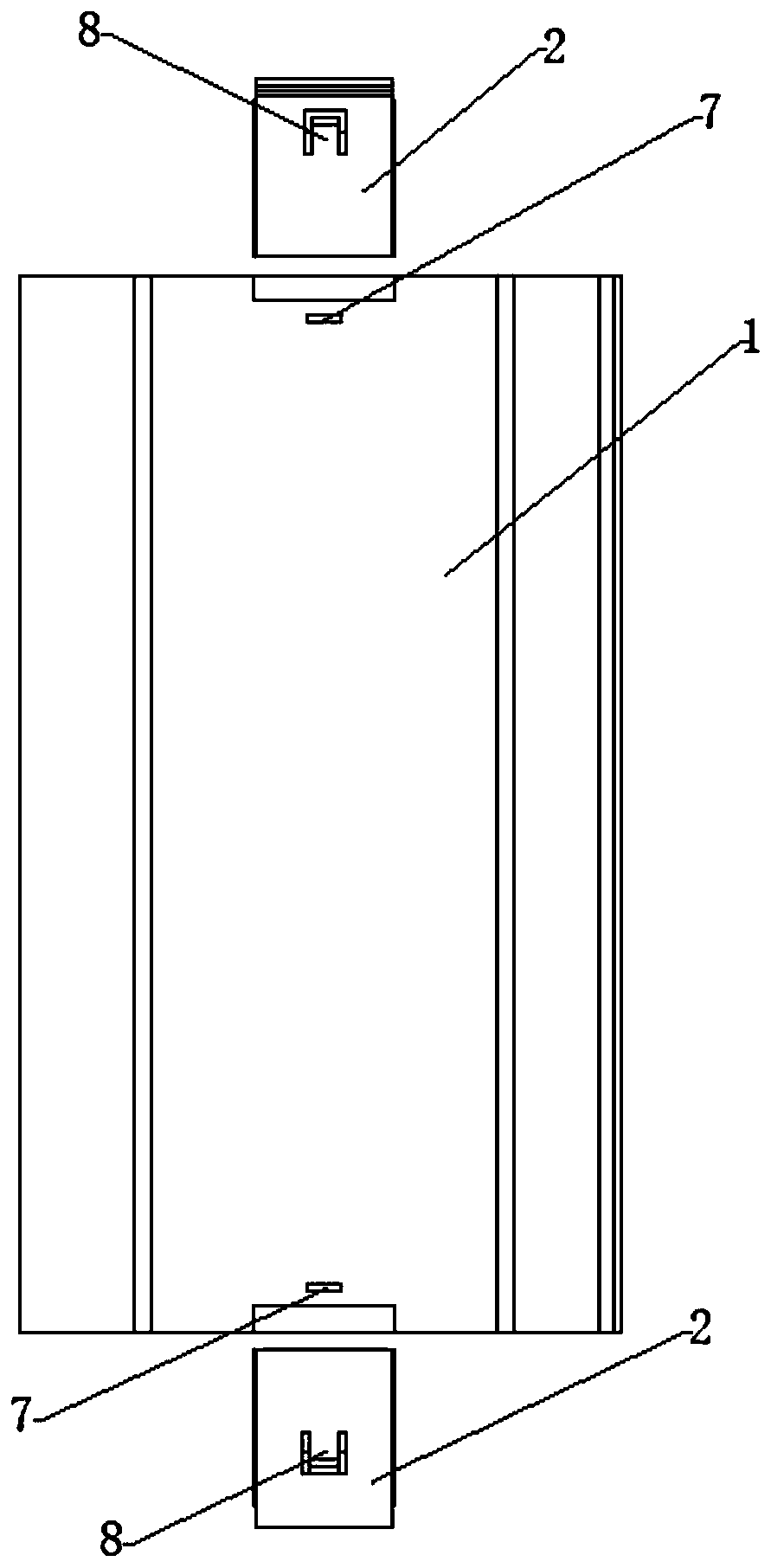

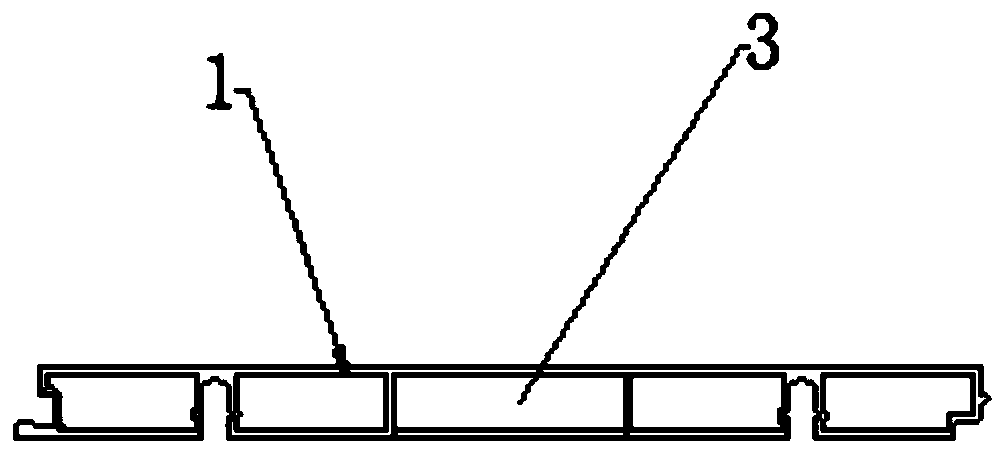

[0039] see figure 1 and figure 2 , The connection structure of the metal profile floor in the present invention includes a floor body 1 and a joint part 2 connected to the bottom body 1 . Wherein the floor body 1 is composed of a metal wire block with an inner cavity, and the short side end portions extending from the cavity to both ends of the floor body 1 constitute the installation cavity 3 .

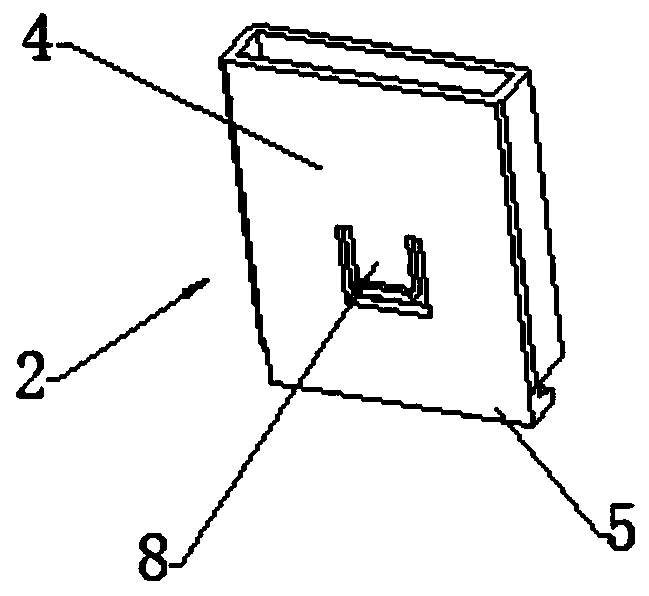

[0040] see Figure 3 to Figure 5, the joint component 2 has a fixing portion 4 and an abutting portion 5 . The abutment portion 5 is adapted to be connected with the abutment portion of the joint part on the floor adjacent to the end of the short side. The abutting portion 5 is a hook-shaped hooking structure 9, and the hook-shaped hooking surface 6 is arranged obliquely to the floor surface of the floor body 1, and the inclined angle has a shape under the pressure on the floor surface. Bring adjacent floorboards closer together. The fixing portion 4 is disposed at an end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com