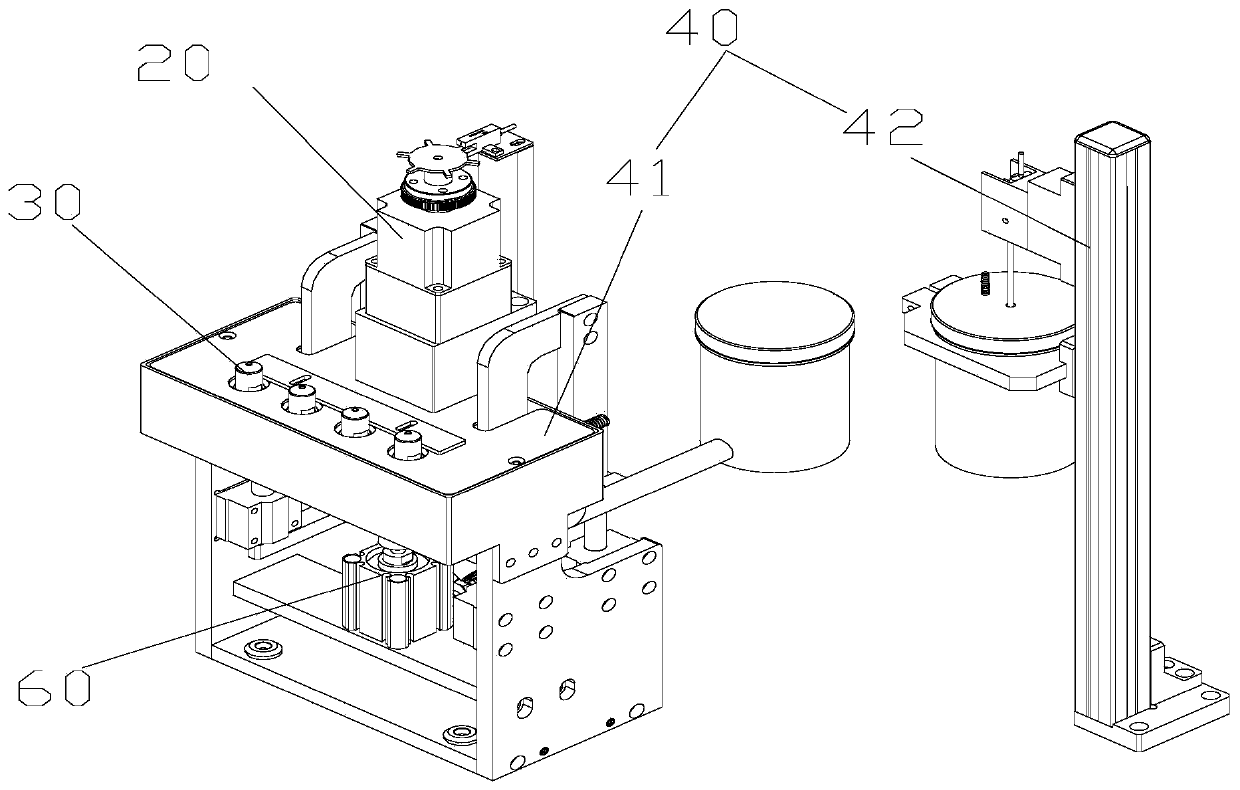

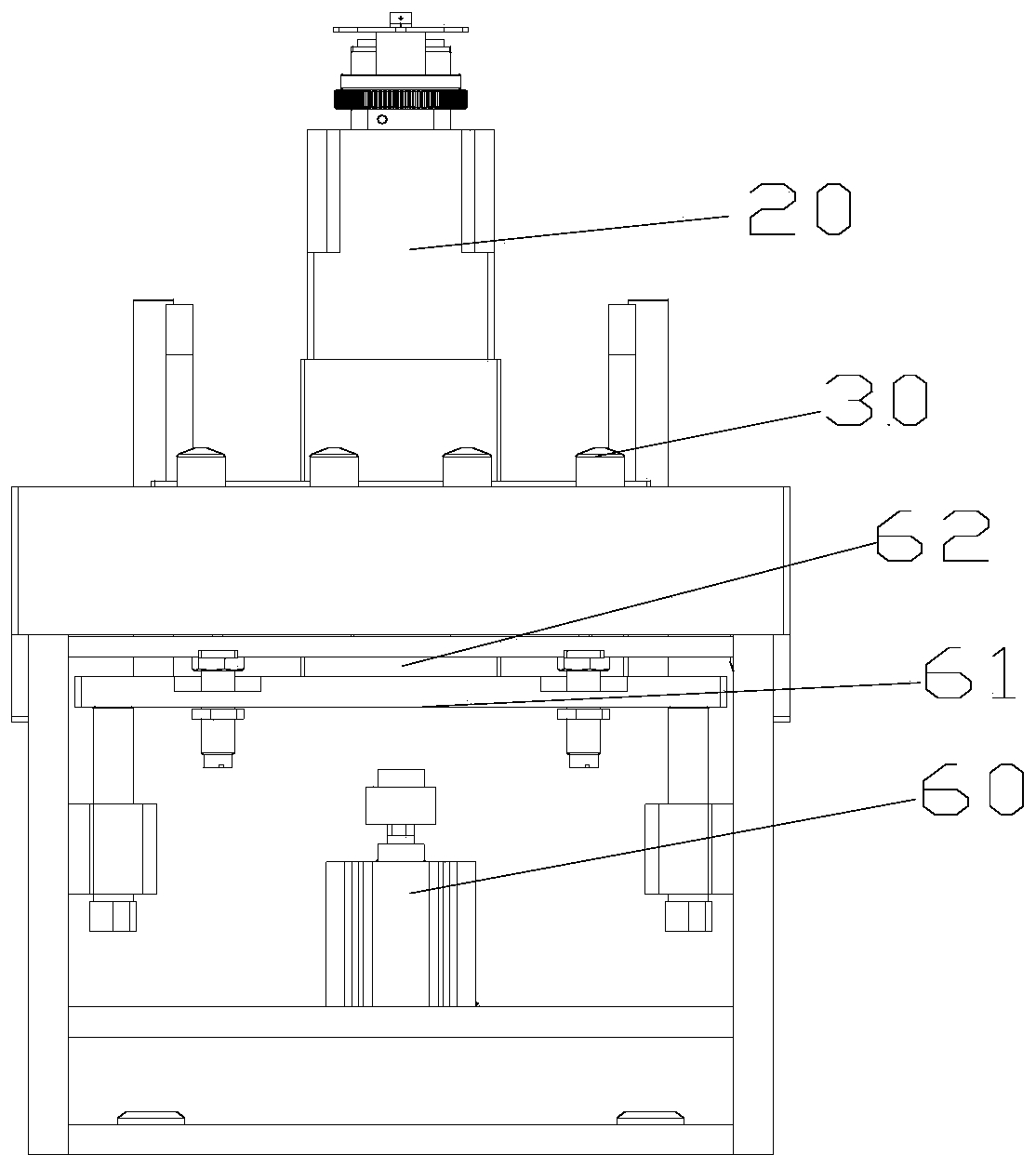

Gluing head, gluing device and gluing process

A technology of gluing device and gluing head, applied in the field of gluing, can solve problems such as uneven gluing of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

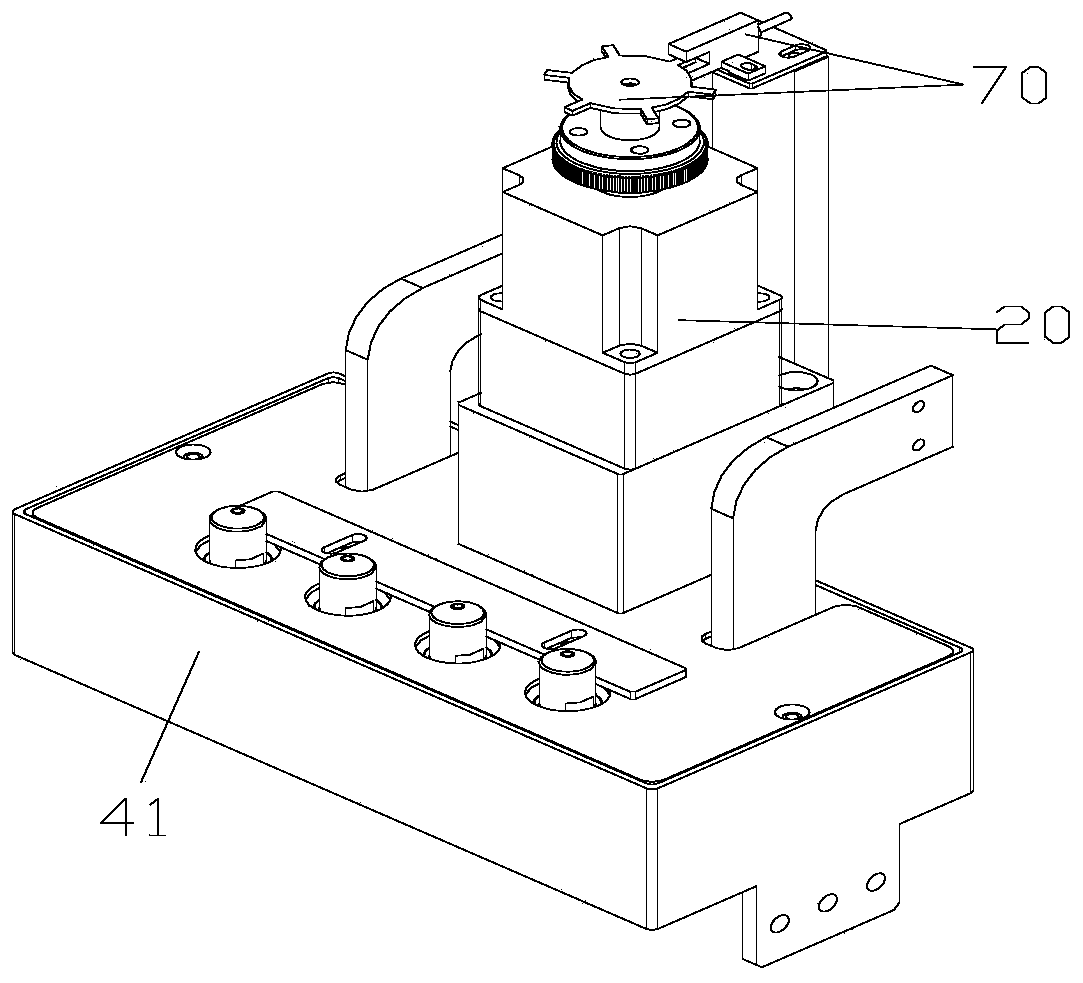

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0029] The present invention provides a gluing head for gluing the workpiece 10, please refer to Figure 5 , the gluing head includes: a gluing part 31, the gluing part 31 is a rotating body with a predetermined axis of rotation, the gluing part 31 is used to contact the surface of the workpiece 10 to apply glue to the surface of the workpiece 10; the drive shaft 32, Drive shaft 32 is connected with gluing part 31, and the axis of driving shaft 32 is arranged in parallel with the predetermined axis of rotation of gluing part 31; The glue applicator is brought into contact with the surface of the workpiece 10 .

[0030] The gluing head in the present invention is mainly used to smear the hole ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap