An expansion valve performance test system and a refrigeration valve performance test system

A testing system and expansion valve technology, applied in mechanical valve testing, fluid tightness testing, machine/structural component testing, etc., can solve unfavorable energy saving and environmental protection, slow working condition stability, difficulty in measuring and controlling the temperature in front of the valve, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

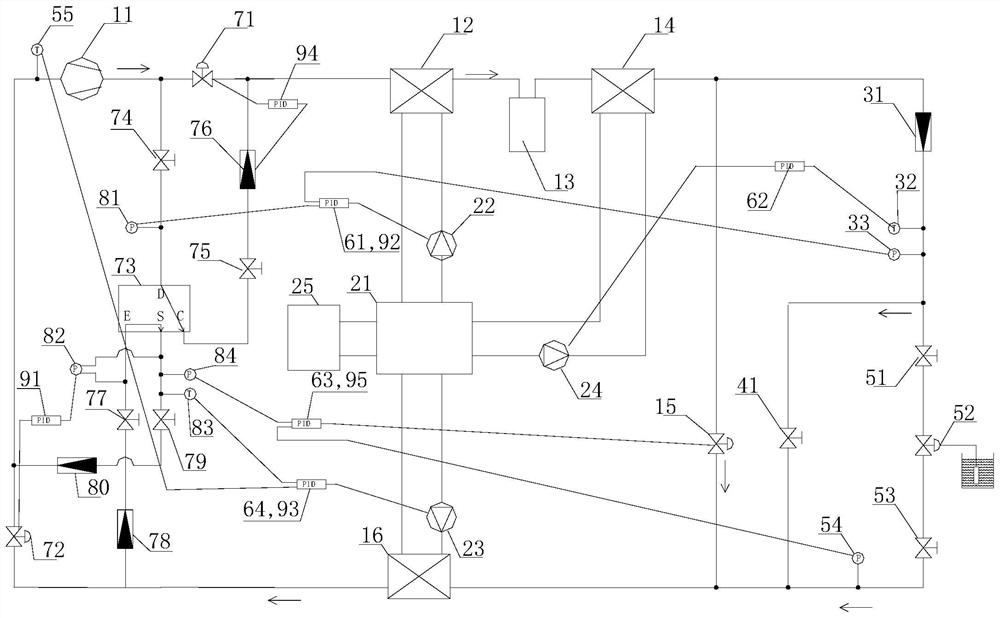

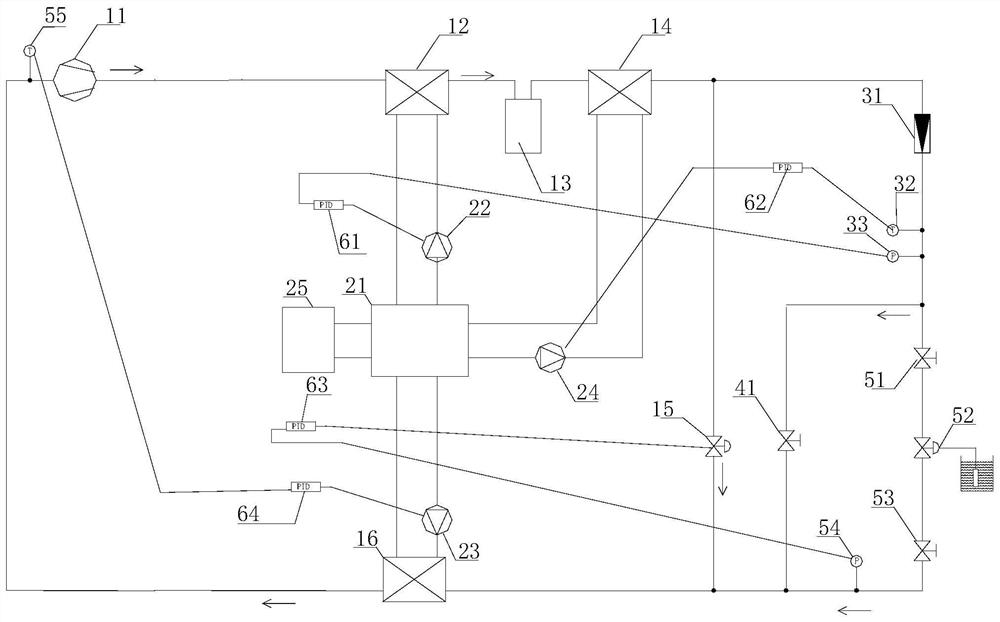

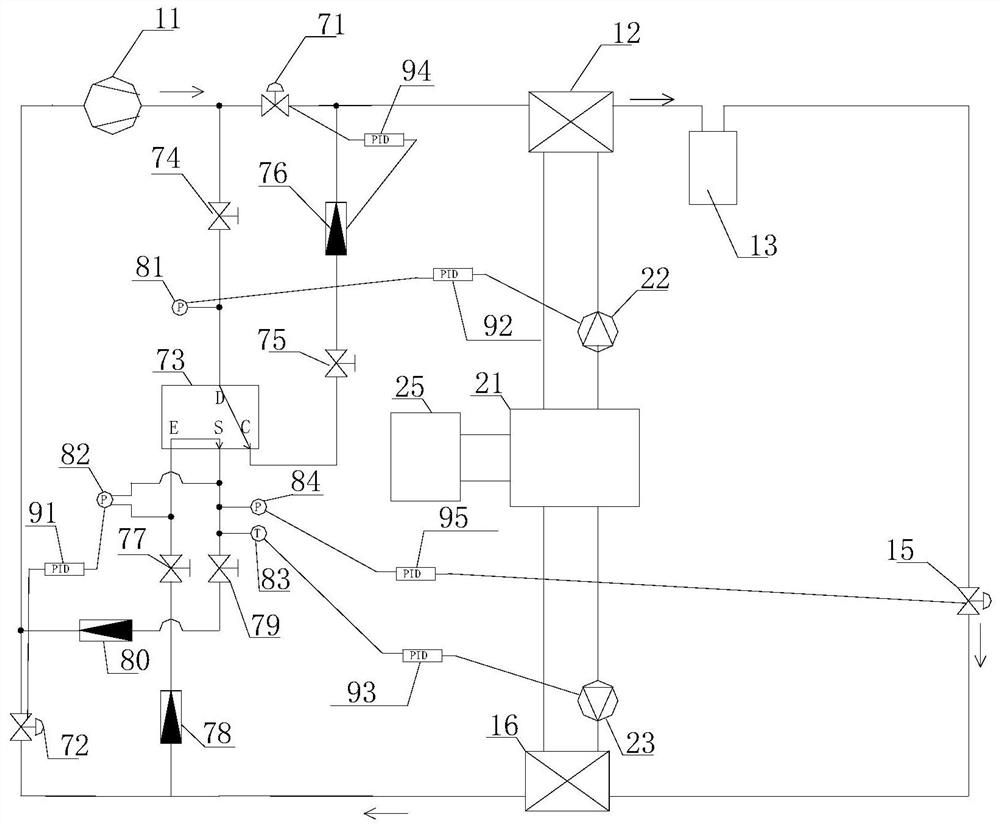

[0056] figure 1 Schematically shows a refrigeration valve performance testing system (hereinafter referred to as the system) according to an embodiment of the present invention, the system can be used for both expansion valve testing and four-way reversing valve testing, the system includes common parts , the special part for expansion valve and the special part for four-way reversing valve. A common part and a dedicated part corresponding to the valve are provided. For example, expansion valve performance testing system such as figure 2 As shown, it includes the common part and the special part of the expansion valve. The performance test system of the four-way reversing valve is as follows: image 3 As shown, it includes the common part and the special part of the four-way reversing valve.

[0057] like Figure 1-3 As shown, the common parts of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com