Plate-exchanging device of printing units for printing presses

A technology for printing devices and printing machines, applied in printing machines, general parts of printing machinery, printing, etc., can solve problems such as printing surface protection that cannot be printed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

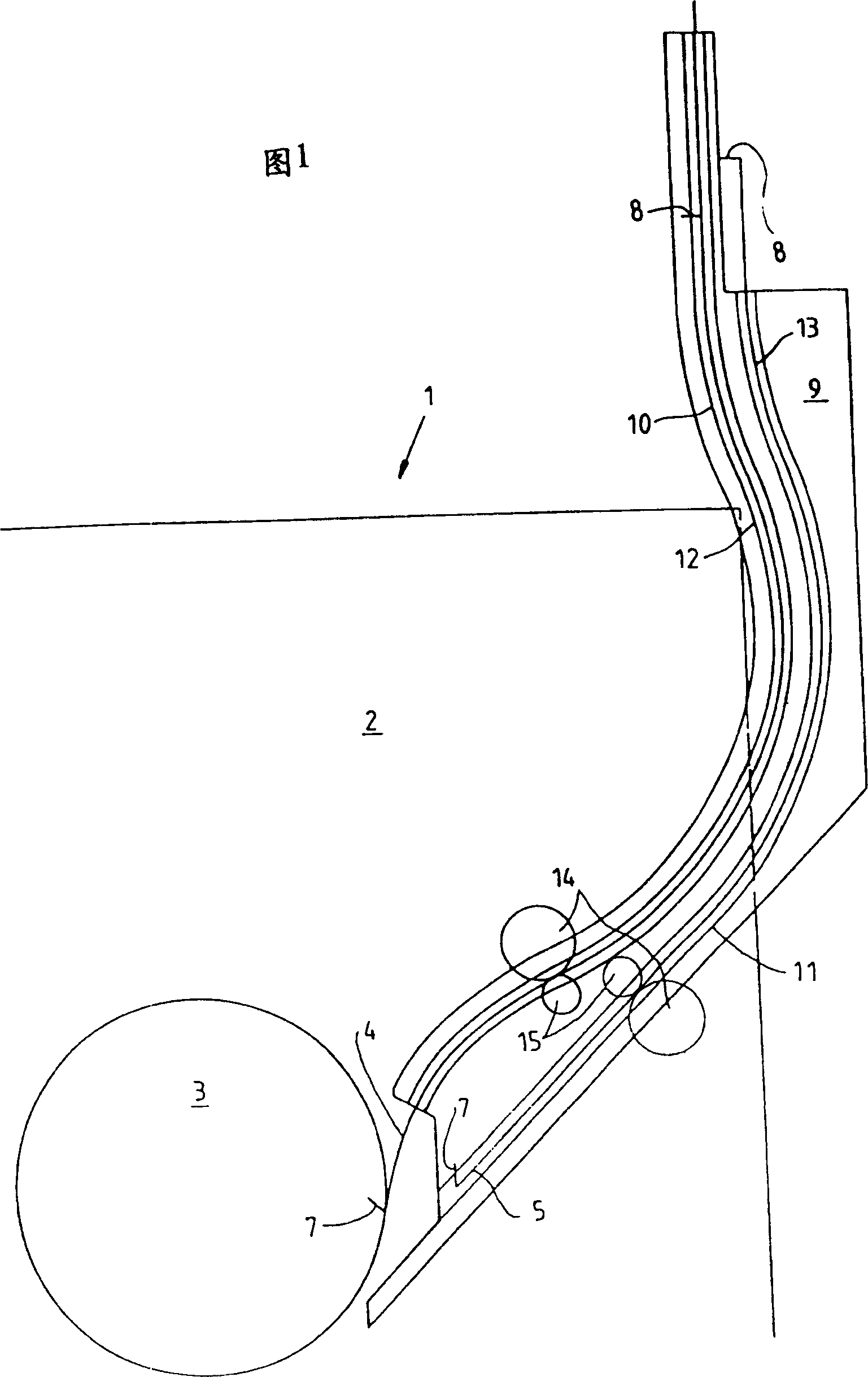

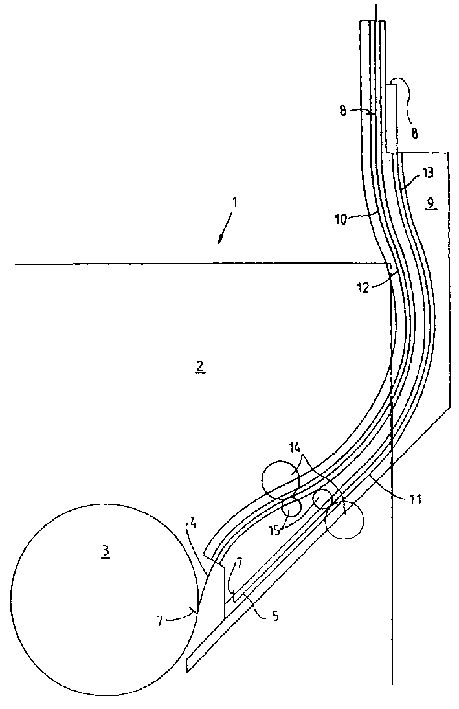

[0016] FIG. 1 shows the solution proposed by the present invention for the upper plate cylinder 3 of the printing device 1. For a device that performs printing on both sides of the connected web, the device of the present invention can also be installed for the lower plate cylinder without difficulty.

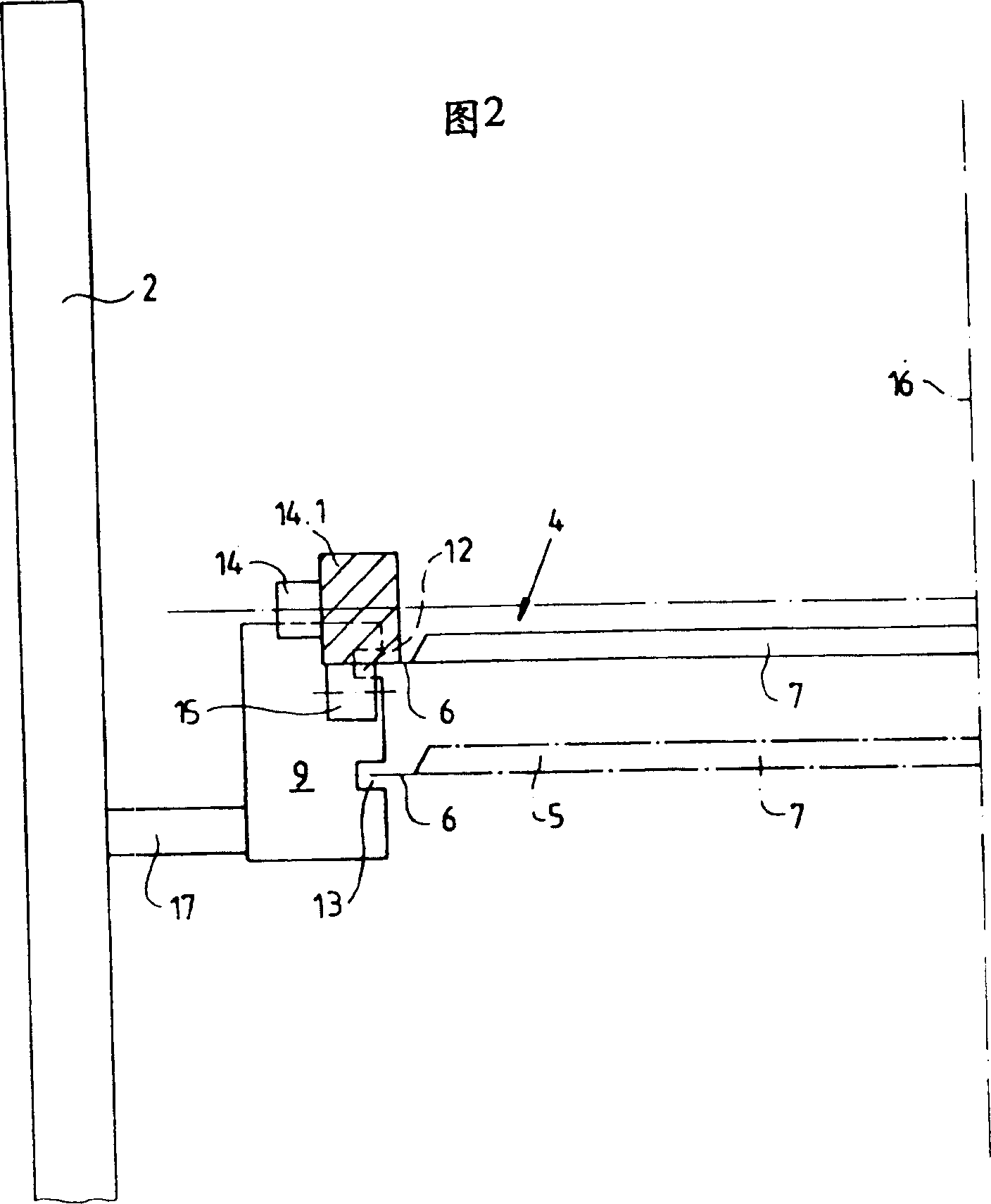

[0017] The master body 9 is fixed to each of the two supporting frames 2 of the printing device 1. At least one first printing plate 4 is placed on each of these profiling bodies 9, which is a new printing plate, which will be installed on the corresponding printing plate cylinder 3 of the printing device 1, and at least one second printing plate 5 is also placed. It was unloaded from the plate cylinder 3 in advance. Each printing plate 4 and 5 has a front edge 7 and a rear edge 8, which are introduced on the periphery of the printing plate cylinder 3 and fix them to a gripping device on the periphery. The lateral edges 6 of the printing plate (see Fig. 2) are guided in the masters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com