Oral care cleaning system utilizing entrained fluid

An oral care system and fluid technology, which can be used in oral care, dental cavity cleaning devices, and cosmetic preparations, etc., which can solve the problems of time-consuming and inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

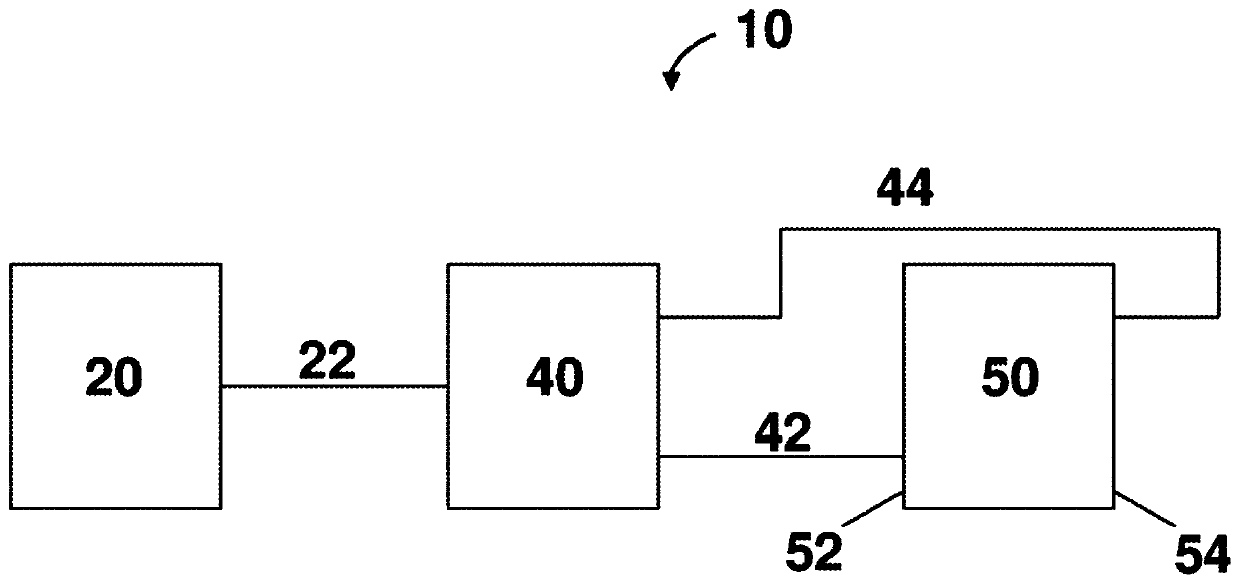

[0200] as a test and presented in figure 1 System 10 consists of a fluid supply reservoir 20 (Model B501, Alloy Products Corp., Waukesha, WI) connected by tubing 22 to a custom programmable reciprocating flow controller 40 capable of A programmable pulse duty cycle of 0-100% pulses and reciprocates a fluid, liquid or gas at a frequency of 0-25Hz. The controller also allows programming of total processing time, amount of time / pulses before reciprocation, and number of reciprocations. Flow controller 40 delivers fluid to appliance 50 through tubes 44 and / or 42 leading to appliance sides 54 and / or 52, respectively. The fixture 50 used for testing purposes was designed to provide a twenty nozzle array of 500 micron diameter nozzles on each side of the fixture. The nozzles were evenly spaced in a straight line pattern with a nozzle pitch equal to 1500 microns (center to center) in the vertical and horizontal directions. During testing, the nozzle outlet was positioned at a fixed...

Embodiment 2

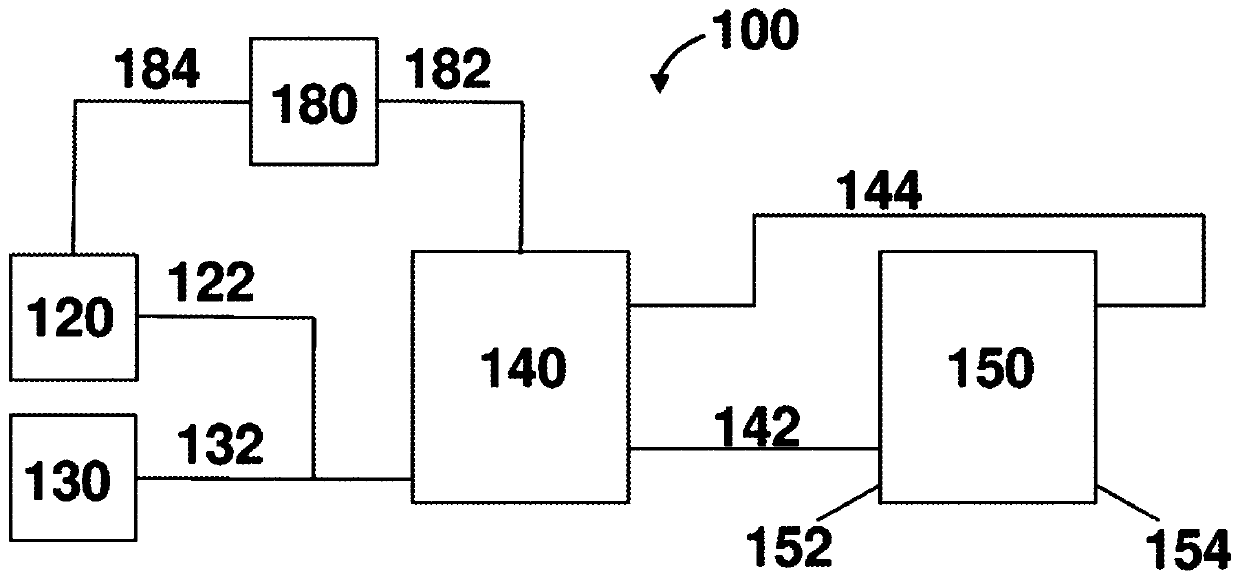

[0223] as a test and presented in figure 2The system 100 consists of a liquid supply reservoir 120 (Model B501, Alloy Products Corp., Waukesha, Wis.) and a gas supply reservoir 130. Liquid reservoir 120 supplies liquid to tube 122 and gas reservoir 130 supplies gas to tube 132, which combine at the junction of tubes 122 and 132 to produce an air-entrained fluid. The fluid (combined liquid and gas) is then conducted through tubing 132 to the first input of a custom programmable reciprocating flow controller 140 capable of a programmable pulse duty cycle of 0-100% The fluid is pulsed and reciprocated at a frequency of 0-25Hz. The controller also allows programming of total processing time, amount of time / pulses before reciprocation, and number of reciprocations. The flow controller also allows a second optional input / output through line 146, which for these experiments used a negative differential pressure (relative to the positive pressure provided through input line 122 via...

Embodiment 3

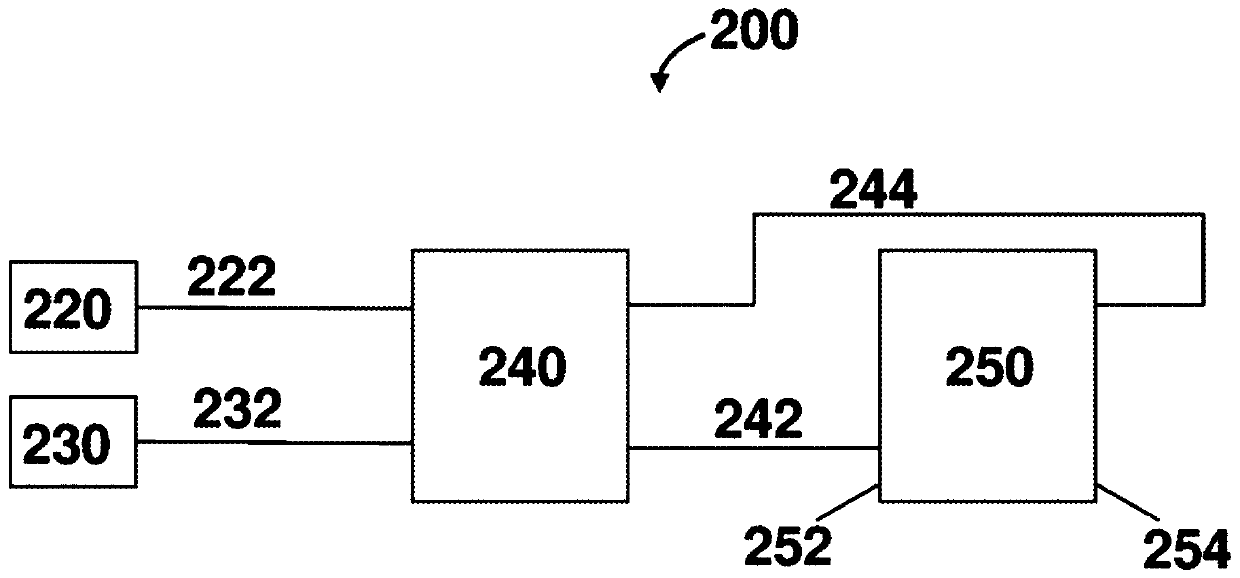

[0228] as a test and presented in image 3 The system 200 consists of a liquid supply reservoir 220 (Model B501, Alloy Products Corp., Waukesha, Wis.), a gas supply reservoir 230 (compressed air tank), a custom reciprocating flow controller 240 and a custom appliance 250. Reciprocating fluid controllers consist of custom built and commercially available components that allow programming of the pulse and direction (reciprocation) of gas pulse and liquid pulse flow (reciprocating motion), as well as synchronization between gas pulses and fluid pulses or asynchronously. This was achieved by triggering a liquid pulse to occur at the start of a gas pulse (NI DAQ model USB-6363, National Instruments, Austin, TX) connected to a pressure sensor (model MLH050PGB06A, Honeywell, Morristown, NJ). Liquid pulse width, frequency, and direction were controlled by a Labview custom program that actuated appropriate solenoid valves (model 71215SN2MN00N0C111P3, Honeywell, Morristown, NJ) to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com