A method for selecting the length of the tail jet flow direction test section for infrared radiation testing

A technology of infrared radiation and tail jet, which is applied in the field of infrared spectrum radiation testing, can solve the problems of measurement result error, background radiation proportion increase, infrared radiation signal attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

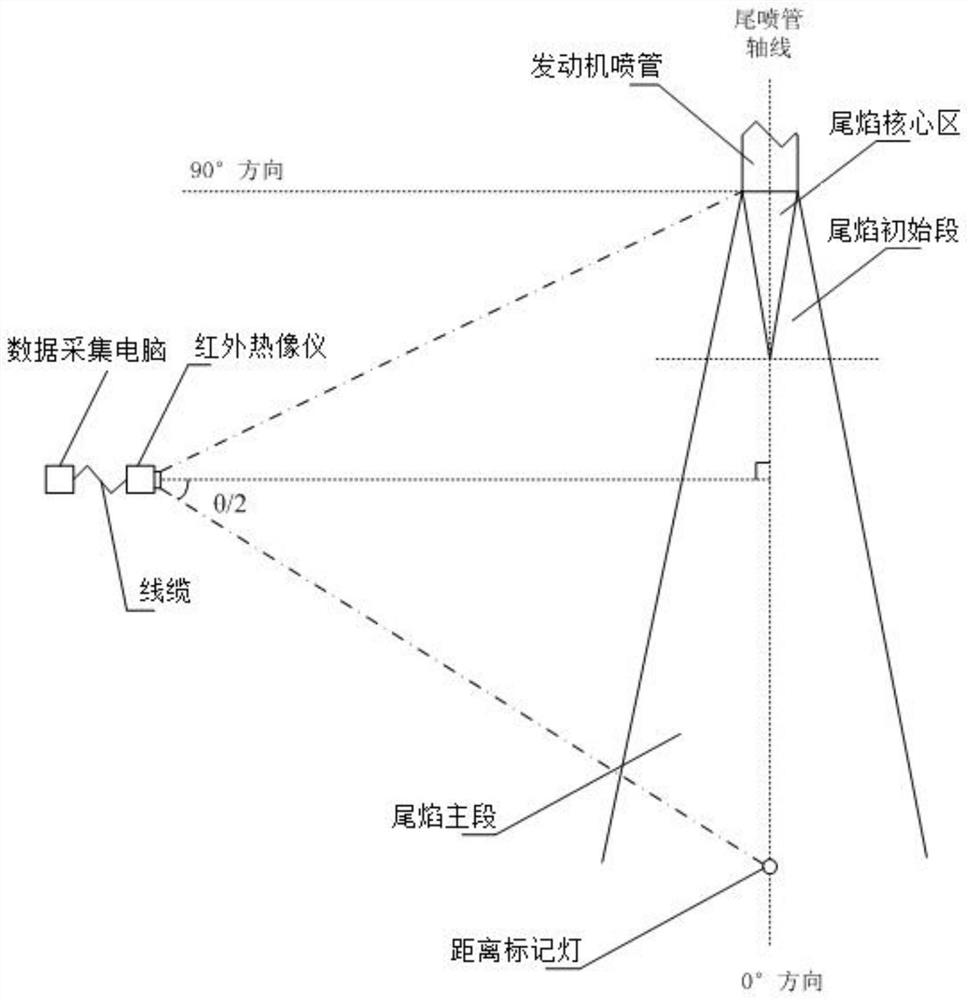

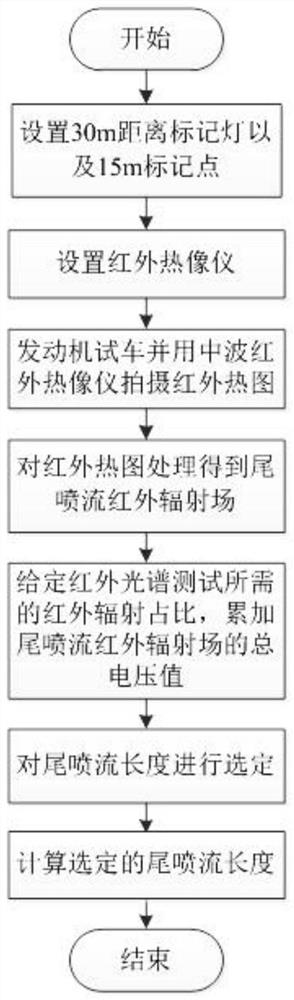

[0042] Such as Figure 1-3 As shown, this embodiment chooses to carry out at night when the wind force level is less than 1, and uses the SC7300M type mid-wave infrared thermal imager to test the engine tail jet flow. When equipped with a 12 mm lens, the field of view of this type of infrared thermal imager is 44°×36°, that is, the horizontal field of view is 44°, the vertical field of view is 36°, and the pixel size is 320×256; a method for selecting the length of the tail jet flow direction test section for infrared radiation testing, and the specific steps of the method as follows:

[0043]Step 1): Set the 30m distance marking light and the marking point at the preset distance. The preset distance of the marking point can be set and modified according to actual needs. Here, the marking point of 15m is used; the laser of the laser collimator is emitted Set the laser collimator at one end of the engine exhaust pipe, and make the emitted laser parallel to the axis of the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com