Fabric for airbag, manufacturing method thereof and airbag

A technology for an airbag and a manufacturing method, which is applied to vehicle safety arrangements, fabrics, textiles, and papermaking, etc., can solve problems such as insufficient dynamic ventilation characteristics, and achieve the effects of excellent internal pressure retention characteristics and excellent dynamic low-ventilation characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

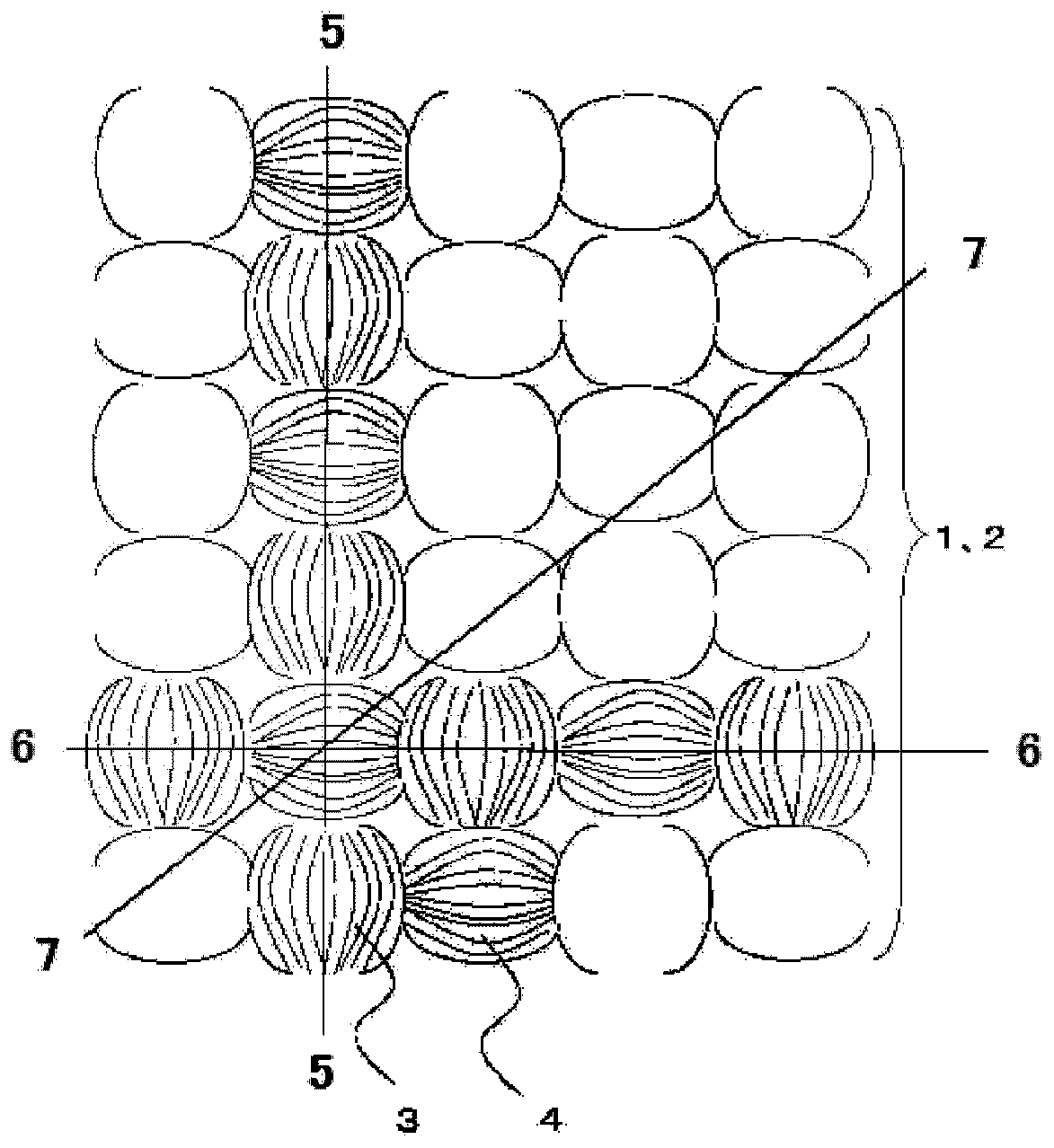

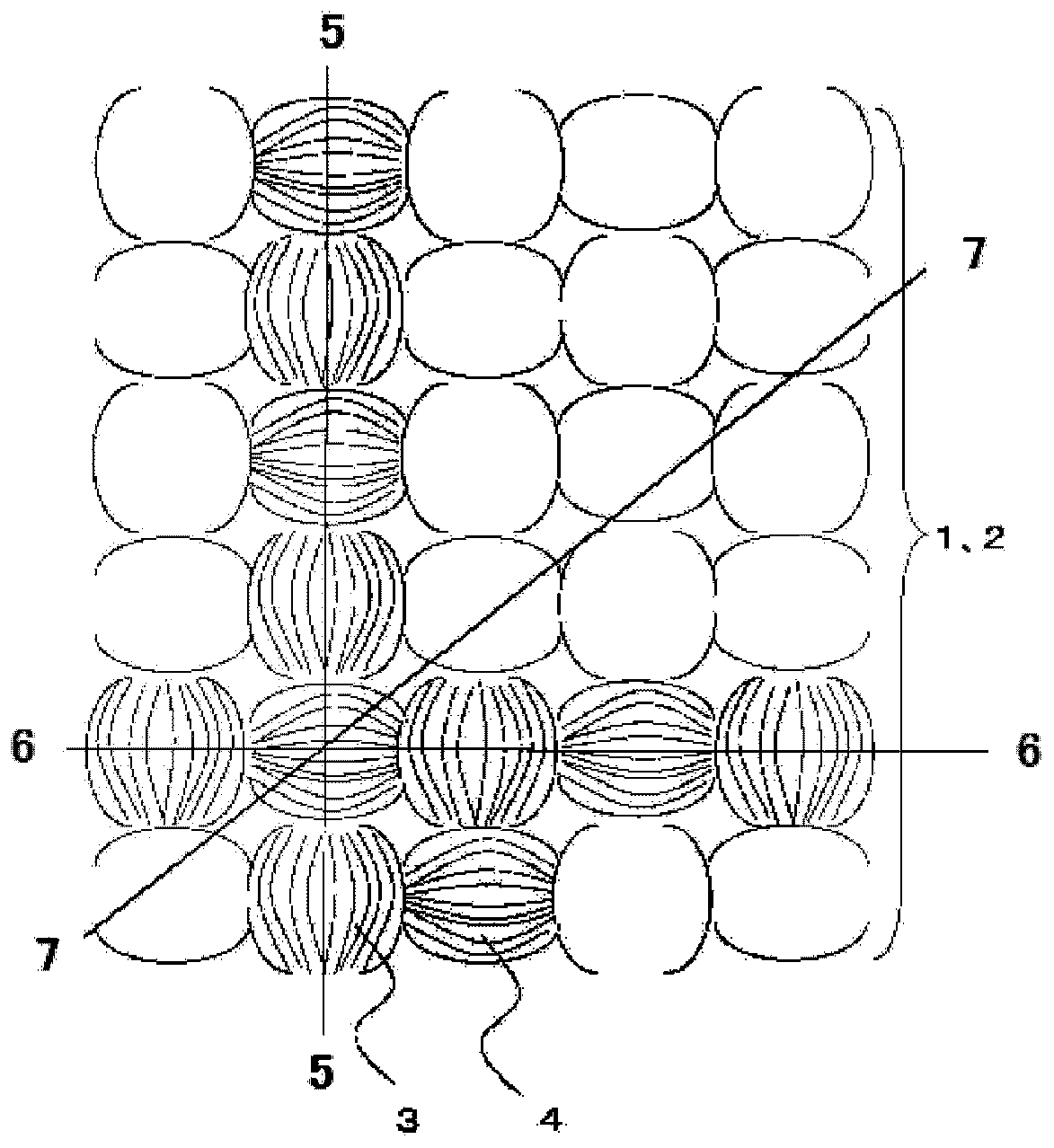

Image

Examples

Embodiment 1

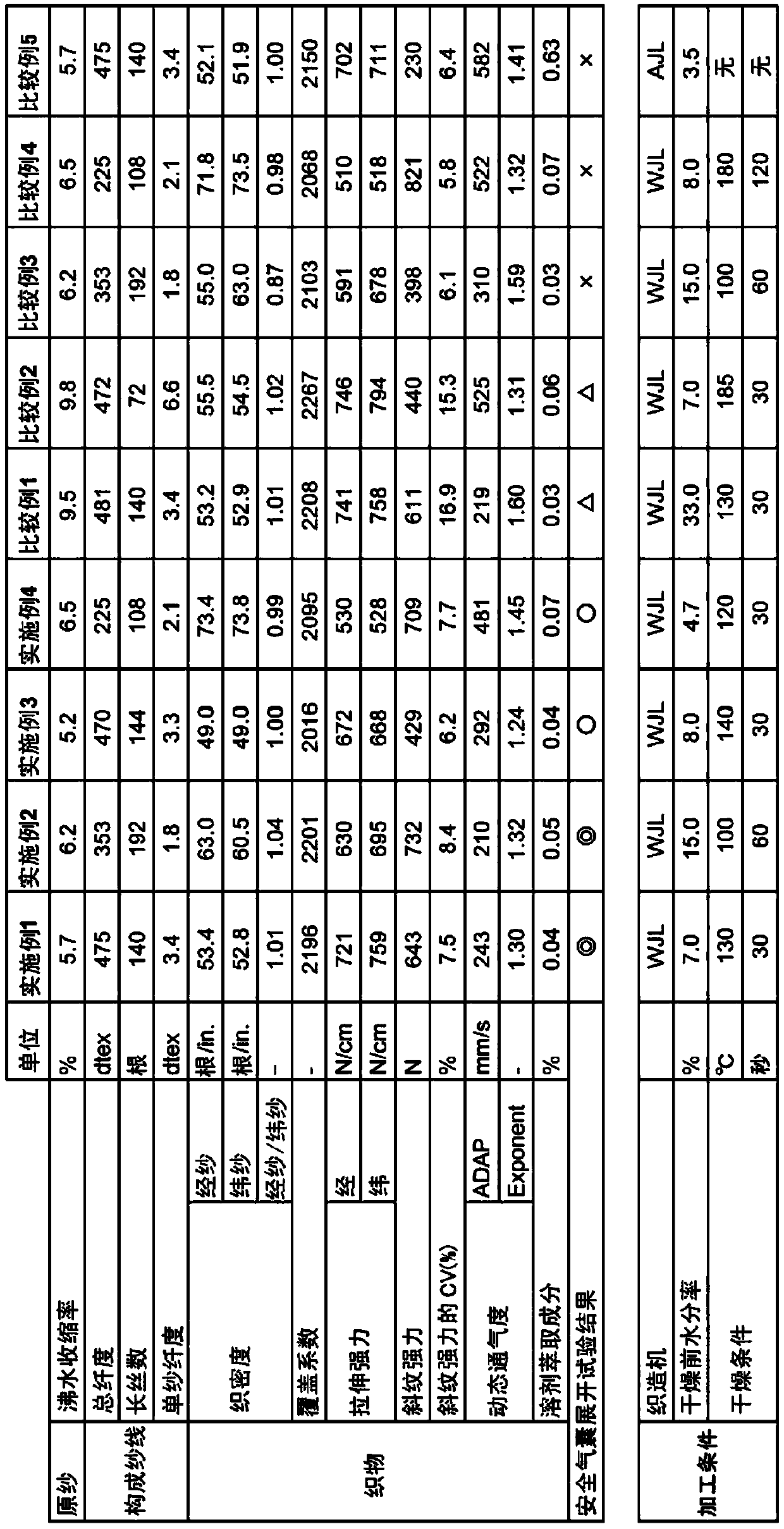

[0080] (Example 1): 475 dtex / 140 multifilament yarns (boiling water shrinkage rate 5.7%) formed by nylon 66 are used as warp and weft yarns in a non-twist state, and a flat fabric is woven by a water jet loom (WJL), Refining and drying were carried out to produce a fabric with warp yarns 53.4 yarns / inch, weft yarns 52.8 yarns / inch, and cover factor (CF) 2196. In addition, high-pressure air was sprayed on the fabric before drying to remove water, and the moisture content was adjusted to 7%. Table 1 shows the physical properties of the obtained fabric. As is clear from Table 1, this fabric is excellent in dynamic low air permeability and internal pressure retention, and is a very excellent airbag fabric.

Embodiment 2

[0081] (Example 2): 353 dtex / 192 multifilament yarns (boiling water shrinkage rate: 6.2%) formed of nylon 66 are used as warp and weft yarns in a non-twisted state, and plain fabrics are woven by WJL, refined and dried, and manufactured A fabric with 63.0 warp yarns / inch, 60.5 weft yarns / inch, and a cover factor (CF) of 2201 is produced. In addition, moisture was sucked and removed from the fabric before drying using a vacuum device, and the moisture content was adjusted to 15%. Table 1 shows the physical properties of the obtained fabric. As is clear from Table 1, this fabric is excellent in dynamic low air permeability and internal pressure retention, and is a very excellent airbag fabric.

Embodiment 3

[0082] (Example 3): 470dtex / 144 multifilament yarns (boiling water shrinkage rate: 5.2%) formed of nylon 66 are used as warp and weft yarns in a non-twisted state, and plain fabrics are woven by WJL, refined and dried, and manufactured A fabric with 49.0 warp yarns / inch, 49.0 weft yarns / inch, and a cover factor (CF) of 2016 is produced. In addition, moisture was sucked and removed from the fabric before drying using a vacuum device, and the moisture content was adjusted to 8%. Table 1 shows the physical properties of the obtained fabric. As is clear from Table 1, this fabric is excellent in dynamic low air permeability and internal pressure retention, and is a very excellent airbag fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com