Steel bar sleeve joint and construction method thereof

A technology of steel sleeves and steel bars, which is applied in the directions of structural elements, building components, building reinforcements, etc., can solve the problems of hidden dangers in the connection quality of steel bars, and difficulty in controlling the width and depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

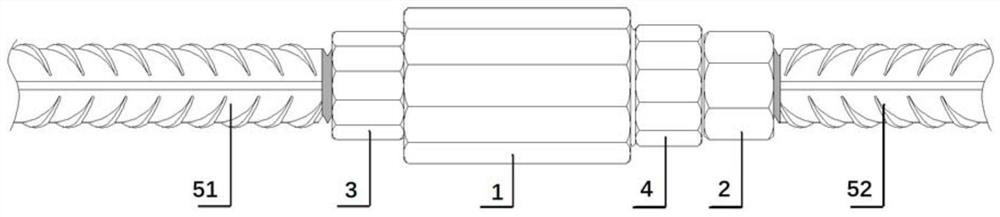

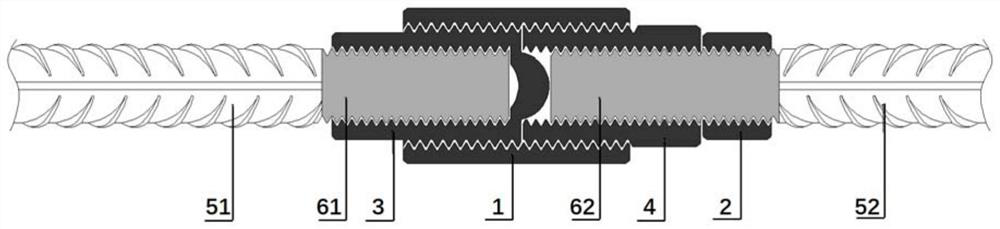

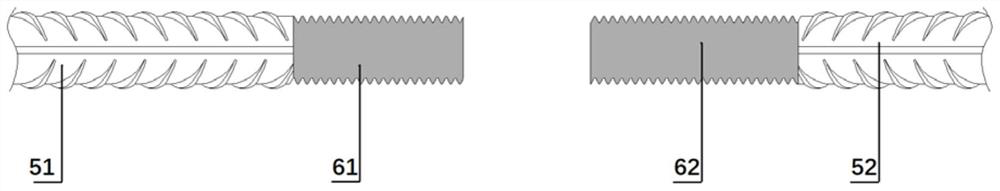

[0033] The present disclosure will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific implementations described here are only used to explain related content, but not to limit the present disclosure. In addition, it should be noted that, for ease of description, only parts related to the present disclosure are shown in the drawings.

[0034] It should be noted that the embodiments in the present disclosure and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present disclosure will be described in detail with reference to the drawings and in conjunction with the embodiments.

[0035] The present invention addresses the shortcomings of the steel bar connection technology in the existing prefabricated buildings. The steel bar sleeve joint of the present disclosure is safe and reliable, efficient connection, strong fault tolerance, and there is no gap afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com