Titanium material, separator, cell, and fuel cell

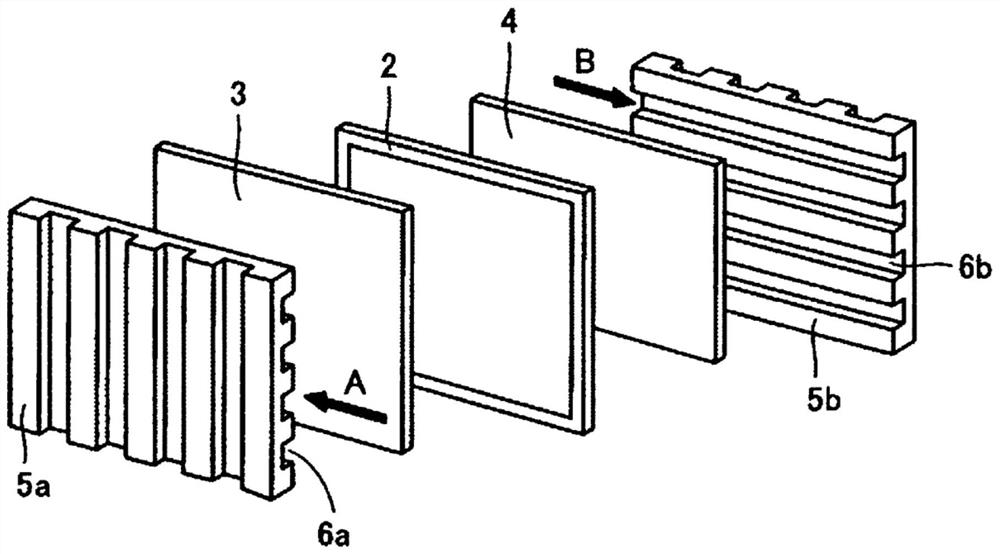

A fuel cell and separator technology, applied in fuel cells, fuel cell parts, metal material coating processes, etc., can solve problems such as rising costs and expensive precious metals, and achieve high power generation efficiency, not easy to surface oxidation, and low cost. The effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0124] In order to confirm the effects of the present invention, various titanium materials were fabricated and evaluated.

[0125] 1. Base material preparation and cold rolling process

[0126] As the base material, the base material A and the base material B described below were prepared. The base material A was formed by cold-rolling JIS Class 1 titanium into a plate shape with a thickness of 0.1 mm. A rolling lubricant containing amine is applied to the surface of titanium to perform cold rolling. The rolling lubricant was used by adding 1% of a lubricating additive for preventing oxidation manufactured by Kaneda Co., Ltd. The lubricant additive contains dialkyldiphenylamine.

[0127] For substrate A, no annealing was performed. Substrate B was obtained by degreasing substrate A with alkali, and then performing bright annealing (BA, Bright Annealing) in a continuous furnace at 720° C. for 30 seconds in an Ar atmosphere. The Ar atmosphere is obtained by flowing industr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com