Folding chair

A folding chair and hinged technology, which is applied to folded chairs, chairs, detachable chairs, etc., can solve the problems of poor hinge rigidity, great influence of height and high cost of composite cross-hinged structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

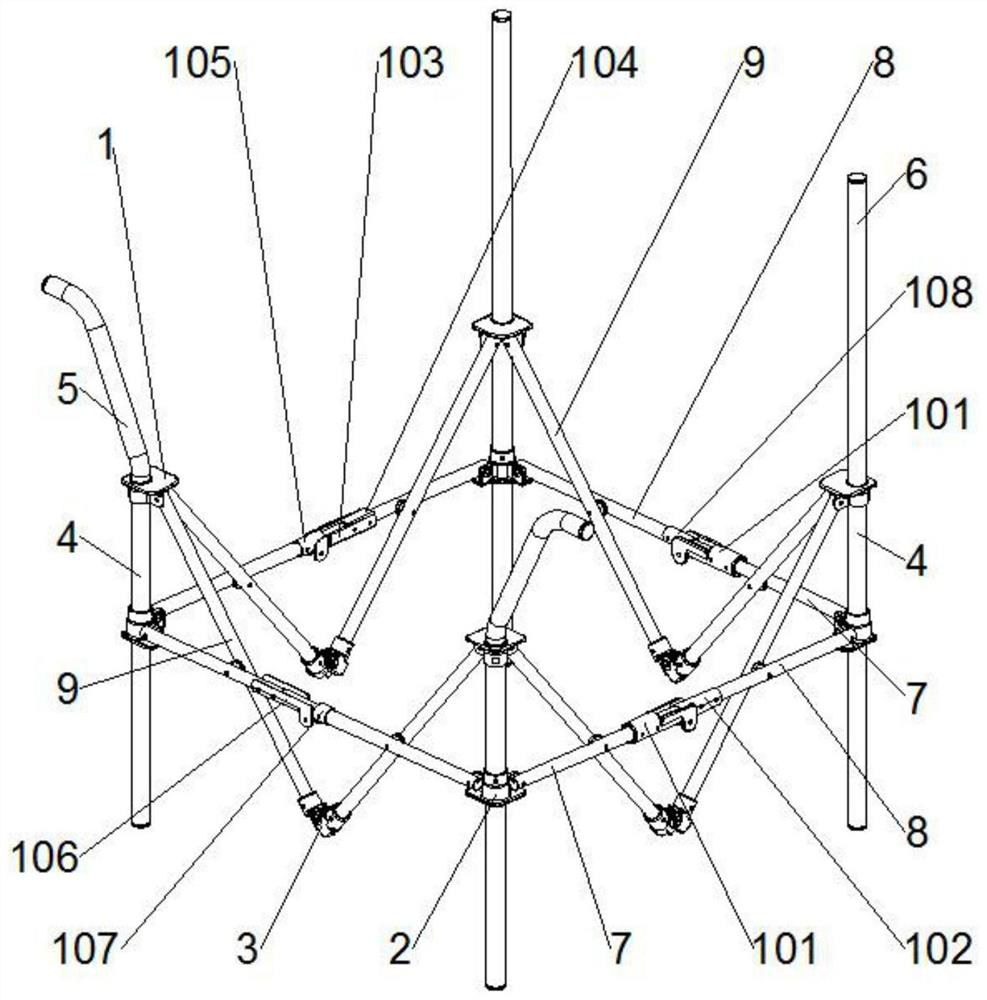

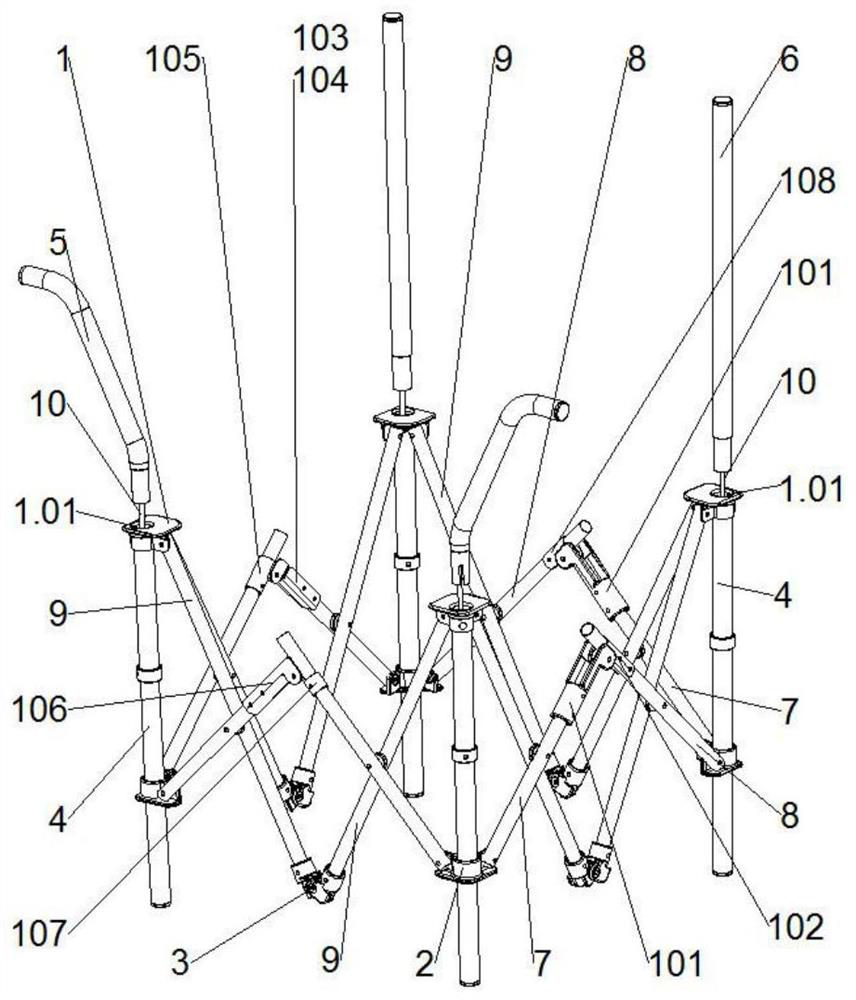

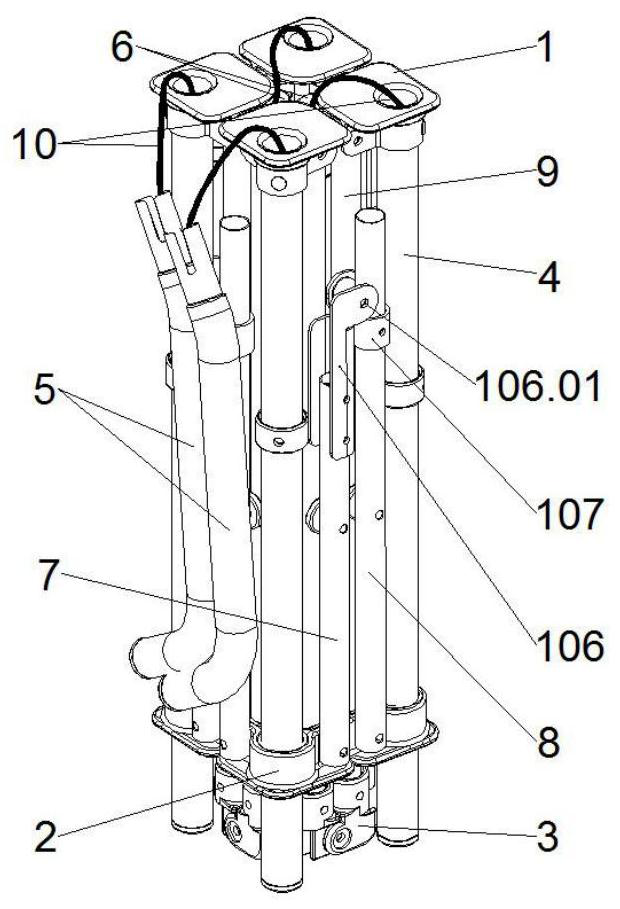

[0112] refer to Figure 1 to Figure 40 , the folding chair includes an upper hinged support (1, 23, 24, 29), a lower hinged support (2, 14, 30), a horizontal hinged tube (7, 8, 12, 13, 18, 19, 27, 28, 43, 44, 45, 46), diagonal cross tubes (9, 21), diagonal cross hinges (3), back tubes (6, 17, 25, 26, 42), armrest tubes (5, 22), rigid in the same plane Articulations (101, 102, 103, 104, 105, 106, 107, 108, 109, 110, 111, 112, 113, 114, 115, 116, 117), bungee cords (10), and leg tubes ( 4), foot plate (15), support (20), rear sliding pipe (16), rotating rod (31), two-dimensional rotating hinge (32), elastic positioning pin (24), horizontal hinged pipe and oblique intersection pipe After being hinged two by two, the horizontal cross pipes are hinged two by two through the same plane rigid hinge device, and the oblique cross pipes are also hinged two by two through the oblique cross hinges. Arrangement, the coaxial lines of the horizontal cross pipes hinged in two on the same pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com