A Productivity Prediction Method for Electric Heating In-situ Mining Thin Oil Shale

A technology for in-situ mining and production capacity prediction, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of different production capacity of oil shale and unmeasured oil output of oil shale, so as to reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

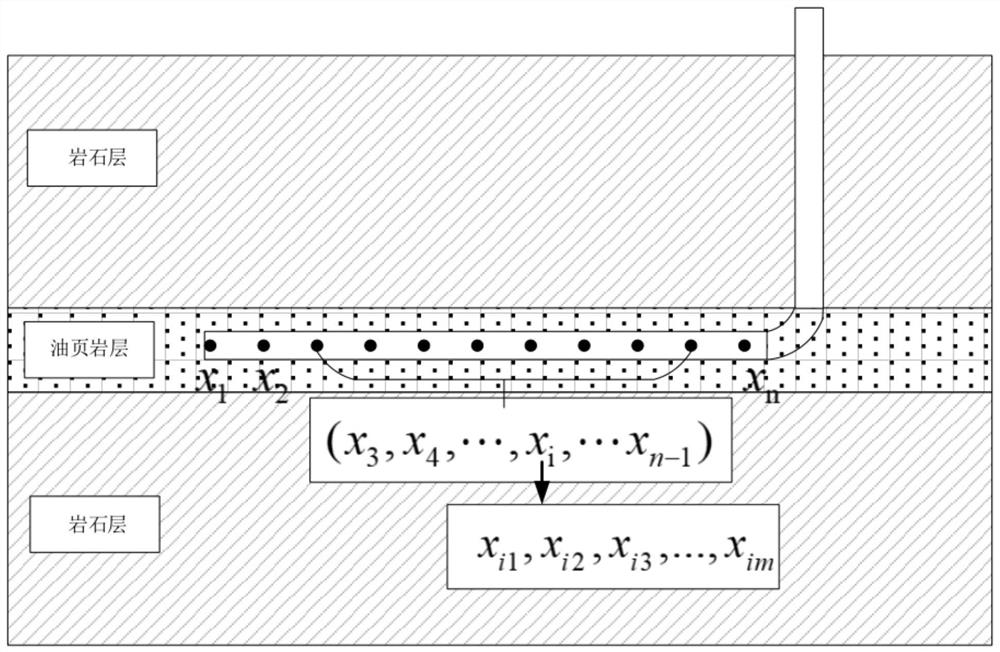

[0105] Referring to each figure, a method for predicting the production capacity of thin-bed oil shale in situ by electric heating, the prediction method includes the following steps:

[0106] Step 1: In a horizontal well for in-situ mining of thin-bed oil shale, select n measurement points equidistant along the well direction, and then take m pieces of oil shale at each measurement point, measure its density, and obtain the effective bulk density ;

[0107] The selected n oil shale measurement points are represented by set B as:

[0108] B={b 1 , b 2 , b 3 ,...,b i ,... b n}

[0109] In the formula, b i is the i-th oil shale measurement point, i is the serial number of the oil shale sample, i=1,2,3,...,n;

[0110] the b i m pieces of oil shale rock set selected by measuring points, use p i Expressed as:

[0111] p i ={b i1 , b i2 , b i3 ,...,b iz ,...,b im}

[0112] In the formula, b iz for b i The zth piece of oil shale rock at the measurement point, z=1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com