An experimental device and experimental method for crack plugging simulation

The technology of an experimental method and experimental device, which is applied in the field of oil drilling testing, can solve the problems of comprehensively evaluating the plugging effect of the plugging material and the pressure bearing capacity of the plugging layer, and achieve the effect of improving the effectiveness of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 provides an experimental device for crack plugging simulation, and the structure will be described in detail below.

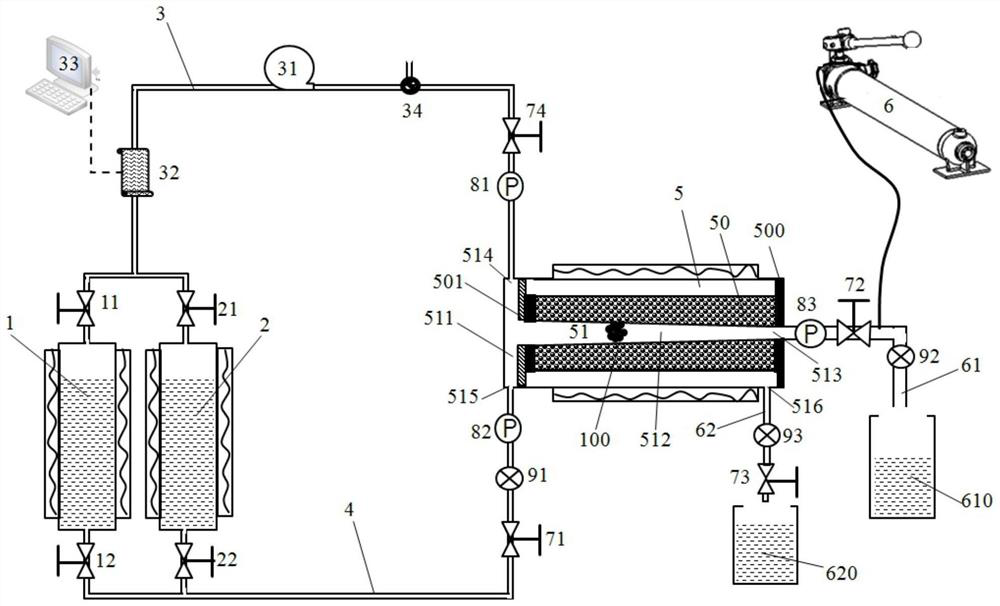

[0049] refer to figure 1 , the experimental device for simulation evaluation of fracture plugging includes a main circulation loop, a first branch 61 and a second branch 62 .

[0050] The main circulation circuit includes a plugging mud tank 1, a formation water tank 2, an upper circulation pipeline 3, a lower circulation pipeline 4, a crack plugging simulator 5, a mud pump 31, a pulse solenoid valve 32 and a computer 33.

[0051] The crack plugging simulator 5 is provided with a long and narrow penetrating crack 51, the penetrating crack 51 includes a penetrating crack liquid inlet 511, a penetrating crack liquid outlet 513 and a crack channel 512, the penetrating crack liquid inlet 511 is thick, and the penetrating crack liquid outlet 513 is small, and the liquid inlet port 511 and the liquid outlet port 513 through the crack are respecti...

Embodiment 2

[0067] Embodiment 2 provides an experimental method for simulating formation water erosion of fractures and fracture surfaces until saturated. The experimental device for simulated evaluation of crack plugging in Embodiment 1 is used. The liquid return control valve 12 of the slurry tank, the liquid discharge control valve 21 of the formation water tank, the liquid return control valve 22 of the formation water tank, the first valve 71, the second valve 72, the third valve 73 and the fourth valve 74 are all in the closed state, Through this experimental method, formation water can be injected into the fracture plugging simulator 5 until the fracture plate 50 is saturated, which is used to simulate the process of formation water injected into the pores of the fracture plate 50 until saturation under the action of a constant pressure difference, specifically including the following steps:

[0068]Step A1: Open the liquid outlet control valve 21 of the formation water tank, the fo...

Embodiment 3

[0074] Embodiment 3 provides an experimental method for simulating dynamic leakage plugging slurry to seal cracks while maintaining a constant pressure difference on both sides of the leakage plugging layer 100. The experimental device for simulation evaluation of crack plugging in Embodiment 1 is used, and the simulation method provided in Embodiment 2 After the experimental method of formation water eroding fractures and fracture surfaces until saturated, the following steps are specifically included:

[0075] Step B1: sequentially open the plugging slurry tank liquid outlet control valve 11, the first valve 71, the plugging slurry tank liquid return control valve 12 and the second valve 72;

[0076] Step B2: set the pressure values of the second back pressure valve 92 and the third back pressure valve 93 to 0.5P, ie 1.5MPa, and set the pressure value of the first back pressure valve 91 to 1.5P, ie 4.5MPa;

[0077] Step B3: Turn on the mud pump 31, and the plugging slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com