Pig feed production device adopting small molecular group water for dispersing and stirring

A small molecular mass water, dispersing and stirring technology, applied in feed, mixer accessories, applications, etc., can solve the problems of reduced metabolism, difficult absorption and utilization of cells in the body, and inability to discharge metabolic wastes and toxins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

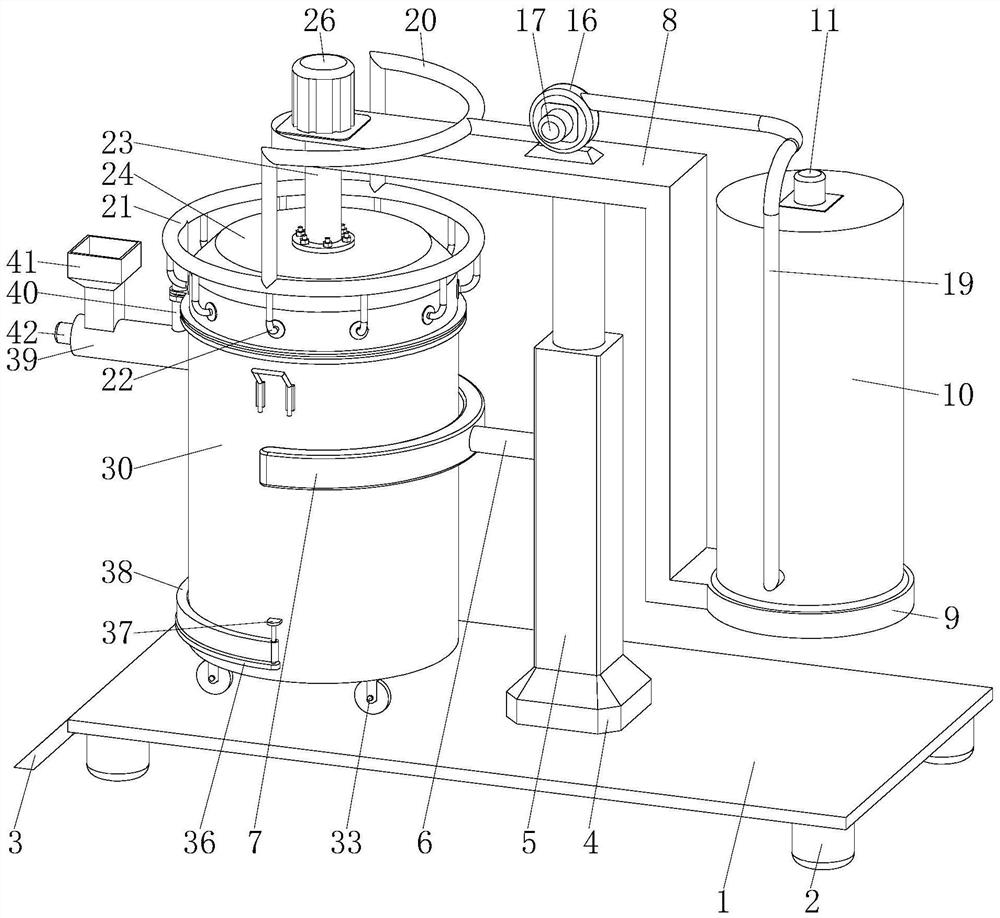

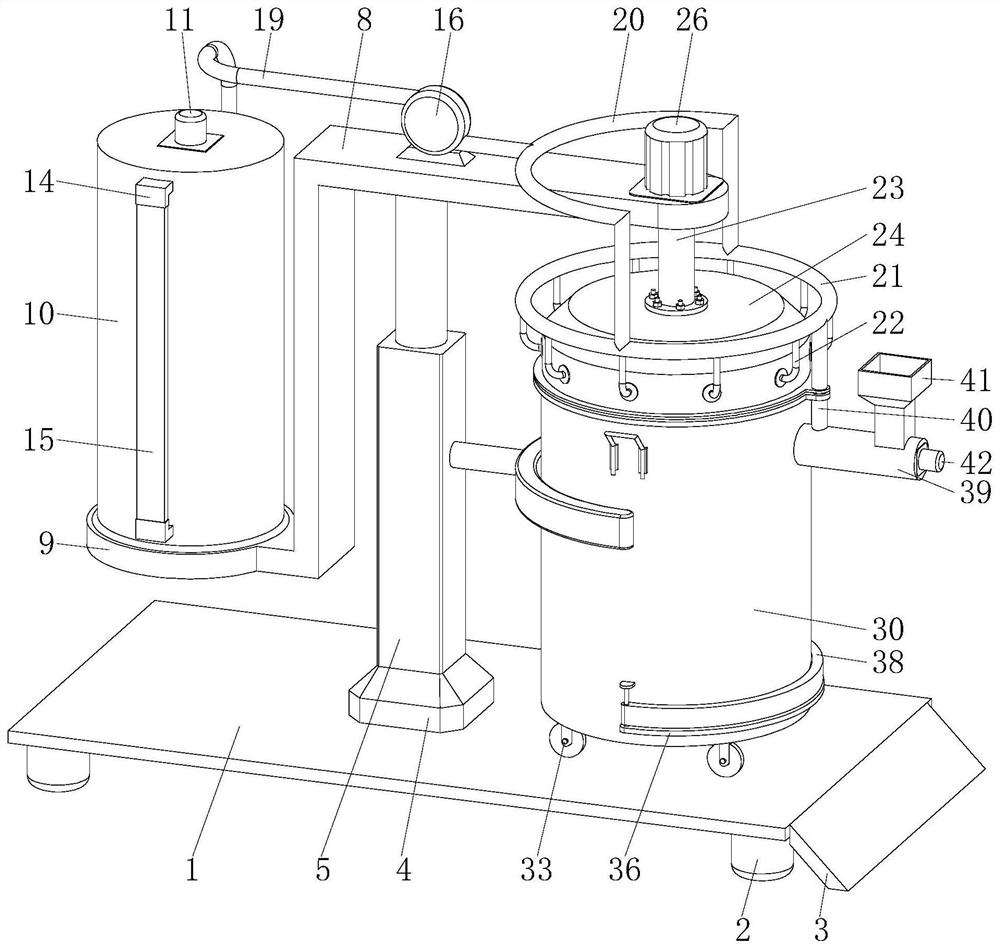

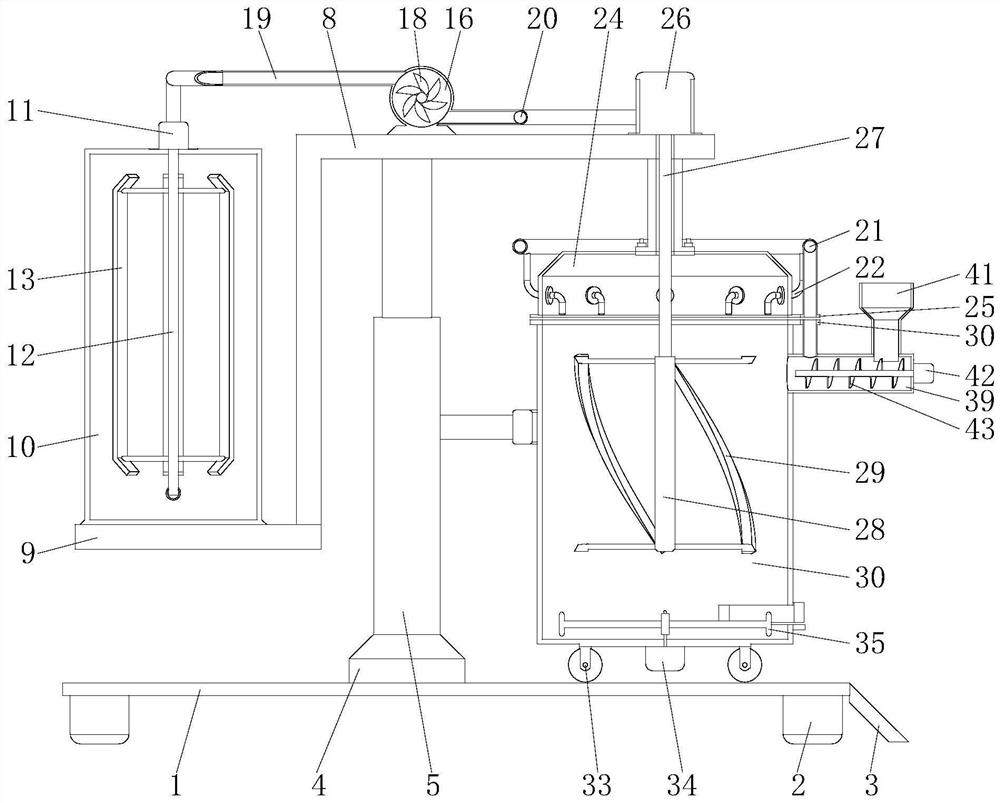

[0033] see Figure 1-7, the present invention provides a technical solution: a pig feed production device adopting small molecular mass water for dispersing and stirring, comprising a bottom plate 1 and a mixing bucket 30, the top of the bottom plate 1 is fixedly installed with a fixed base 4, and the top of the fixed base 4 is fixed A hydraulic lifting column 5 is installed, and the bottom of the L-shaped fixed frame 8 is fixedly equipped with an installation base 9, and the top of the installation base 9 is fixedly installed with a rotating motor 11, and the output end of the rotating motor 11 is fixedly installed with a rotating rod 12, and the rotating rod 12 The outside is fixedly sleeved with a stirring rod 13, the top of the L-shaped fixed frame 8 is fixedly installed with a water pump 16, one side of the water pump 16 is fixedly installed with a water pump motor 17, and the output end of the water pump motor 17 is fixedly installed with a water suction fan blade 18, On...

Embodiment 2

[0036] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the bottom of the bottom plate 1 is fixedly installed with support feet 2, there are four slope plates 3, and the four support feet 2 are rectangular and fixedly installed on the bottom plate 1, one end of the bottom plate 1 is fixedly installed with a slope plate 3, one side of the hydraulic lifting column 5 is fixedly installed with a connecting rod 6, and the end of the connecting rod 6 away from the hydraulic lifting column 5 is fixedly installed with an arc-shaped limit frame 7, the arc The shape limiter 7 is suitable for the specifications and sizes of the mixing barrel 30 and the positions are corresponding.

[0037] In this embodiment, the four supporting feet 2 are rectangular and fixedly installed on the bottom of the bottom plate 1, so that the entire equipment can be supported stably, and a slope plate 3 is fixedly installed on one end of the bott...

Embodiment 3

[0039] Such as Figure 1-7 As shown, the present invention provides a technical solution on the basis of Embodiment 1 and Embodiment 2: one side of the water tank 10 is fixedly installed with a connecting pipe 14, and there are two connecting pipes 14, and the two connecting pipes 14 are symmetrical Installed on one side of the water tank 10, a transparent water level pipe 15 is fixedly installed between the two connecting pipes 14, the end of the rotating rod 12 away from the rotating motor 11 runs through the water tank 10 and extends to the inside of the water tank 10, and the stirring rod 13 has six, six A stirring rod 13 is circumferentially fixedly installed on the outside of the rotating rod 12, and one end of the suction pipe 19 away from the water pump 16 runs through the side of the water tank 10 away from the connecting pipe 14, and the two ends of the branch outlet pipe 20 away from the water pump 16 are symmetrically fixed and installed on the The top of the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com