Compressor for process during punching and/or riveting

A pressing cylinder, pressing force technology, applied in the field of presses used in processes during stamping and/or riveting, to reduce pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

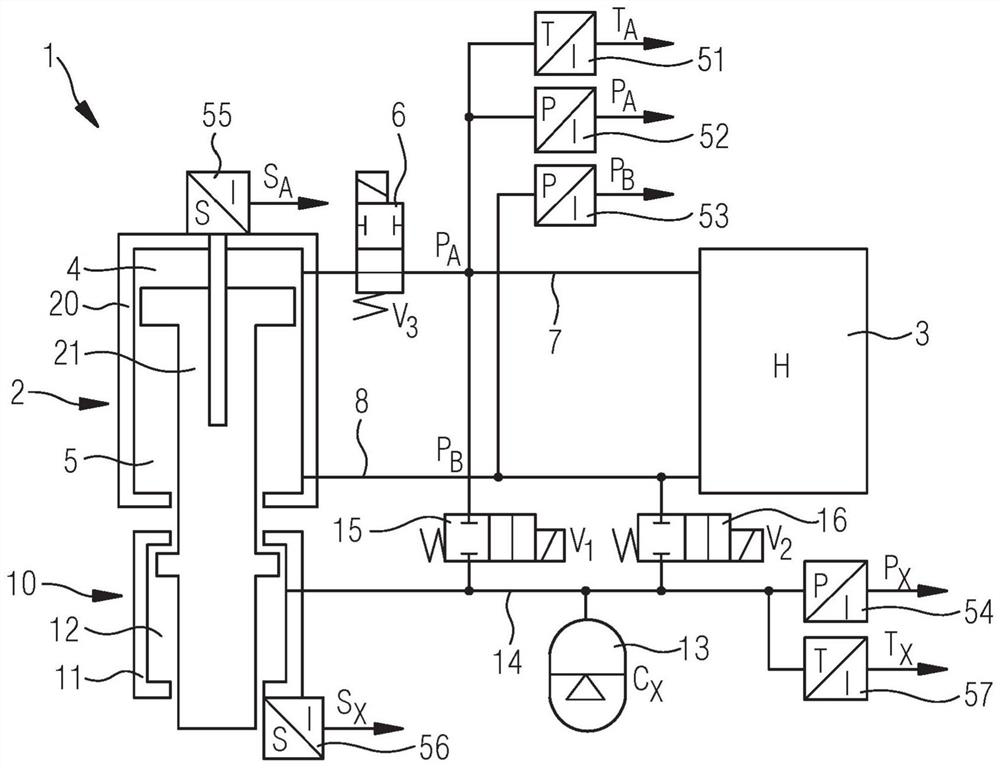

[0037] figure 1 A joining device 1 with a joining drive 2 having a pressing device 10 is shown in FIG. The coupling drive 2 has a differential piston with a piston chamber 4 and an annular chamber 5 . The piston chamber 4 is connected to the hydraulic unit 3 via a supply line 7 . A valve 6 is arranged in the supply line 7 . In the embodiment shown, the reversing valve V is set 3 As valve 6 , the switchover valve can be used to establish and disconnect the connection between hydraulic unit 3 and piston chamber 4 .

[0038] The annular chamber 5 is connected to the hydraulic unit via a supply line 8 . No valve is provided in this supply line 8 . To detect the position of the piston, a position sensor 55 is provided. The pressure P provided by the hydraulic circuit is detected via the pressure sensor 52 A . The temperature of the hydraulic medium T A Received by temperature sensor 51. To detect the pressure P in the supply line 8 to the annular chamber 5 B , a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com