A kind of artificial eye cleaning equipment

A technology for cleaning equipment and prosthetic eyes, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, eye implants, etc., and can solve problems such as insufficient cleaning of prosthetic eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

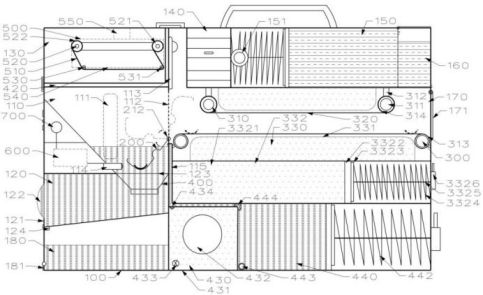

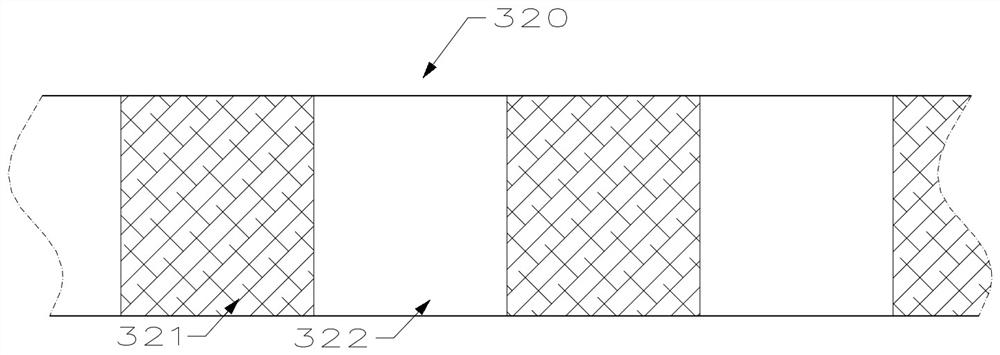

[0083] like figure 1 As shown, the cleaning device for the prosthetic eye of the present application includes a housing 100, a prosthetic eye salvaging assembly 200, a debris removal assembly 300, a power assembly and a control unit.

[0084] The housing 100 includes a prosthetic eye cleaning bin 110 and a sticking and removing component placement bin 170; the prosthetic eye cleaning bin 110 is a bin body structure for holding cleaning liquid, and an ultrasonic cleaner 114 is arranged therein; The said sticking and removing component placement bin 170 is located on one side of the prosthetic eye cleaning bin 110, and communicates with the prosthetic eye cleaning bin 110 through the prosthetic eye output port 112, for placing the said debris sticking and removing component 300; the said The height of the prosthetic eye output port 112 is higher than the liquid level of the cleaning liquid inside the prosthetic eye cleaning chamber 110; the side of the sticking and removing com...

Embodiment 2

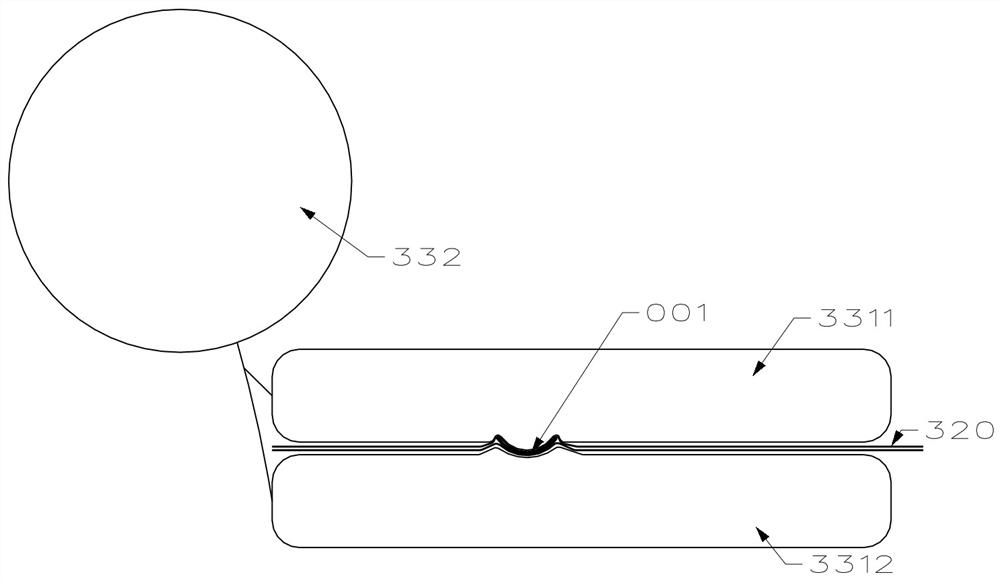

[0113] During the trial production of the cleaning device of the first embodiment of the present application, it was found that in the process of sticking and removing the debris on the artificial eye 001 in the solution of the above-mentioned embodiment, the spatial position of the artificial eye 001 is relatively random, and after many times of sticking and removing The control unit 700 controls the first arrangement assembly 313 and the second arrangement assembly 314 to run simultaneously, and the way of transporting the artificial eye 001 to a position close to the mouth of the placement chamber is likely to cause the artificial eye 001 to wear out (the artificial eye 001 is moved to close After placing the position of the silo body opening, it may rub against the silo body door 171, or fall off the tape 320 and contact the inner wall of the sticking assembly silo 170 to cause wear); in order to solve the above problems, reduce the artificial eye 001 caused by the cleaning ...

Embodiment 3

[0126] Considering that the cleaning agent in the solution in the above-mentioned embodiment will accumulate a lot of floats and sediments after being used for many times, it cannot be used continuously; the process of replacing the cleaning agent is cumbersome, and for the prosthetic eye wearer who often travels on business, it is necessary to carry it with them. A large amount of normal saline is unrealistic, and it will be subject to many restrictions (out of stock, long distance, etc.);

[0127] The embodiment of the present application has carried out certain improvements on the steps of the above-mentioned embodiment on the basis of the above-mentioned embodiment, thereby achieving the purpose of prolonging the use time of the cleaning agent and improving the practicability of the cleaning equipment of the present application; specifically:

[0128] The step 1 is: the user opens the door 171 of the placement chamber, and places the prosthetic eye 001 to be cleaned on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com