Dual droplet size print head

A print head, inkjet print head technology, applied in printing and other directions, can solve problems such as ink energy fluctuation and reducing the overall quality of printed images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

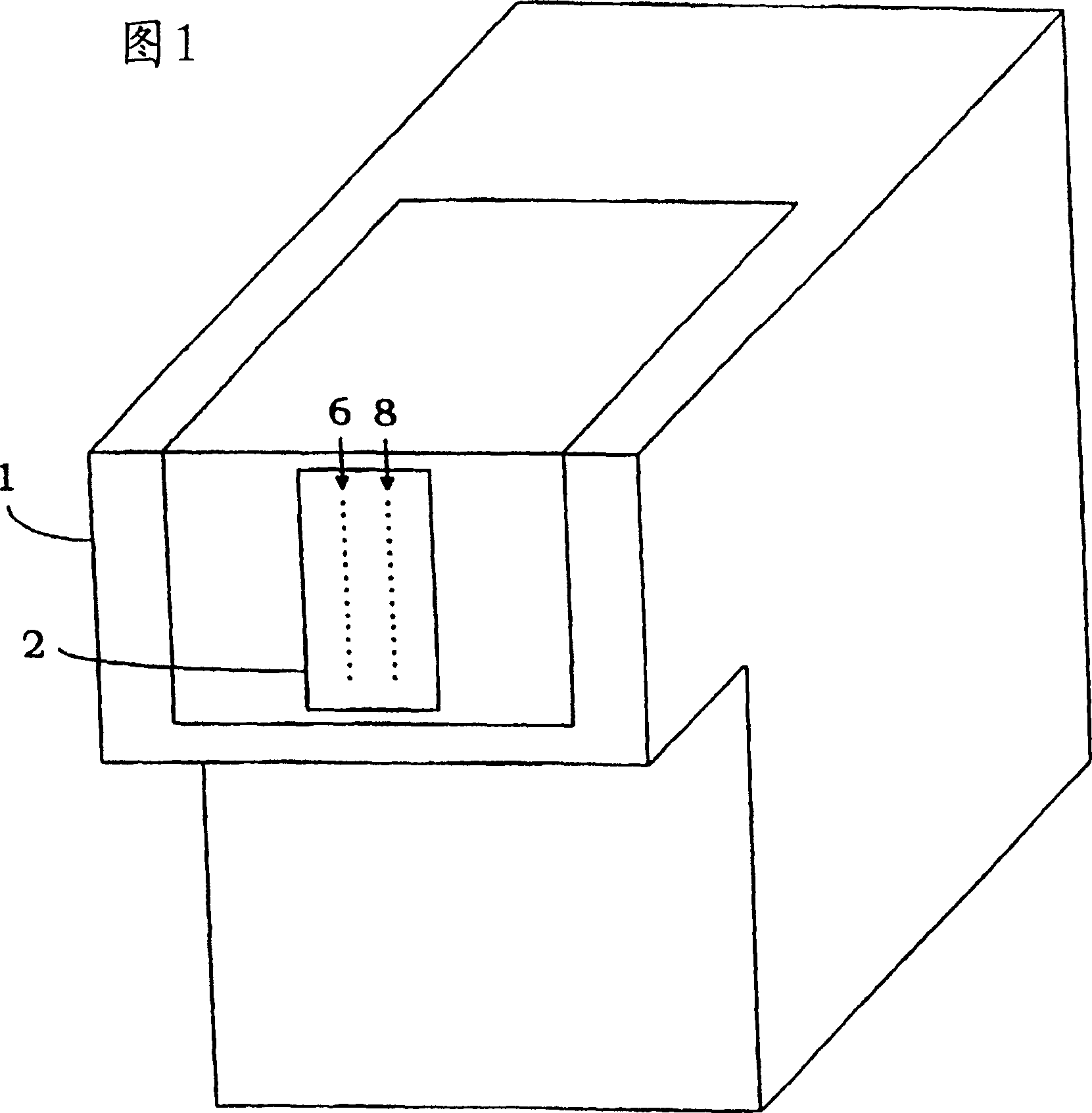

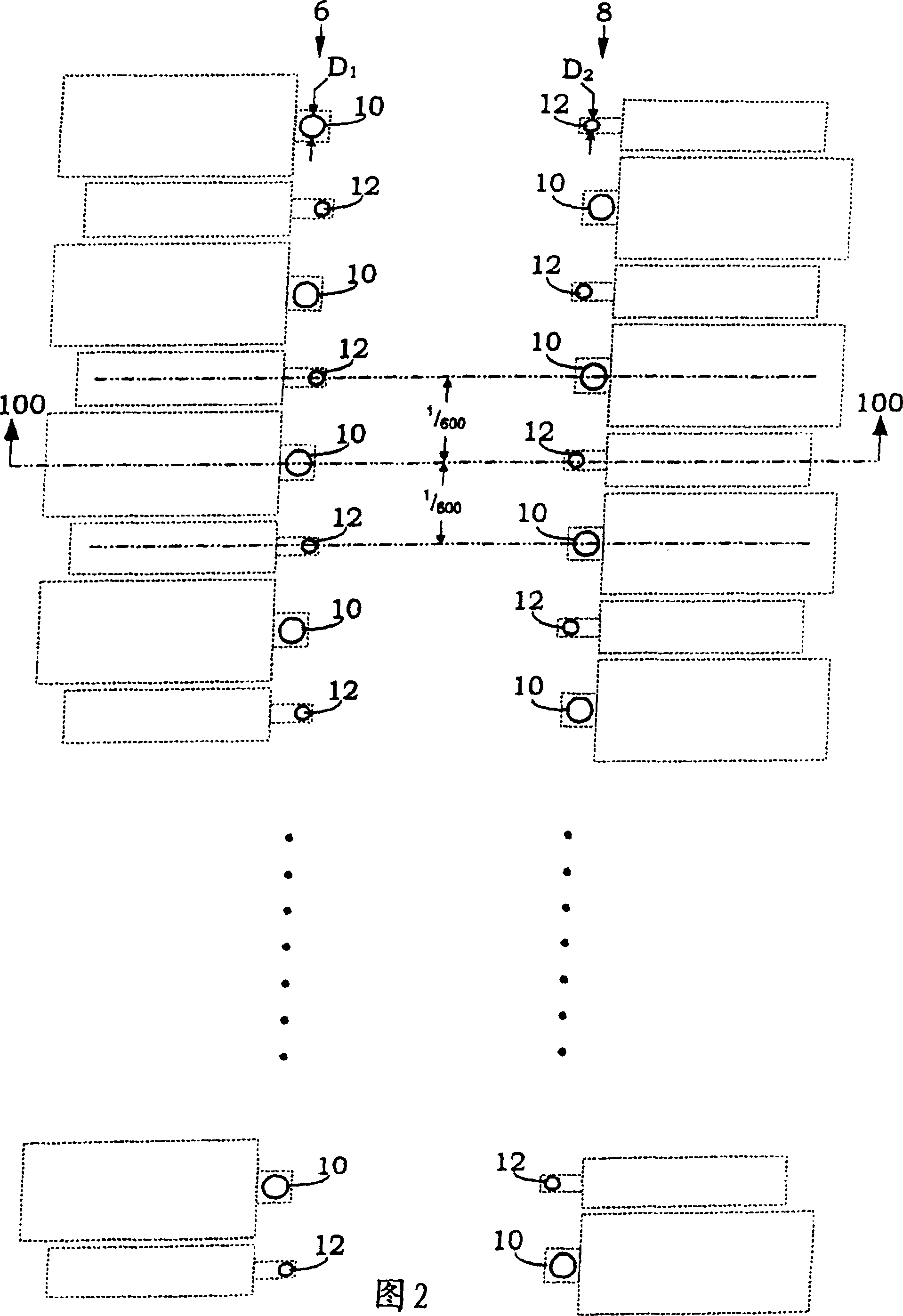

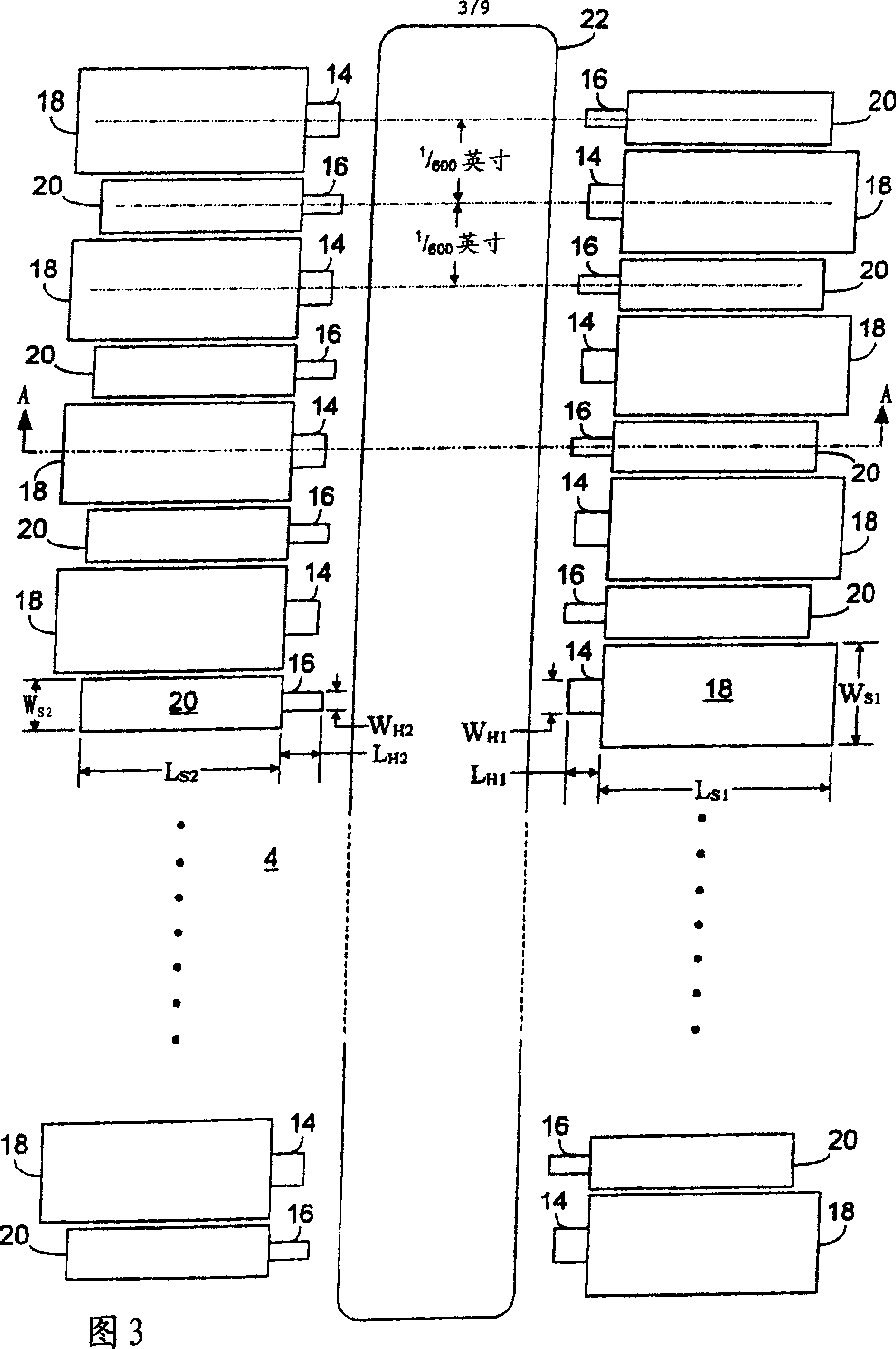

[0024] Shown in FIG. 1 is an inkjet printhead 1 having a nozzle plate 2 on which arrays of nozzles are arranged in a left column 6 and in a right column 8 . FIG. 2 shows an enlarged view of an array of nozzles in a nozzle plate 2 . The nozzle array includes first nozzles 10 and second nozzles 12 , wherein the positions of the first nozzles 10 and the second nozzles are arranged alternately in each of columns 6 and 8 . Each first nozzle 10 in the left column 6 is horizontally aligned with a second nozzle 12 in the right column 8, and each first nozzle 10 in the right column 8 is horizontally aligned with a second nozzle 12 in the left column 6 . In the preferred embodiment of the invention, the vertical spacing between adjacent nozzles in each column is 1 / 600 of an inch.

[0025] As shown in Figure 2, the first nozzle 10 has a diameter D 1 , which is larger than the diameter D of the second nozzle 12 2 . Hereinafter, the first nozzle 10 and the second nozzle 12 are also re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com