Vehicle body structure

A body and vehicle technology, applied in the direction of superstructure, substructure, vehicle parts, etc., can solve the problems such as difficult to fasten the buffer beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

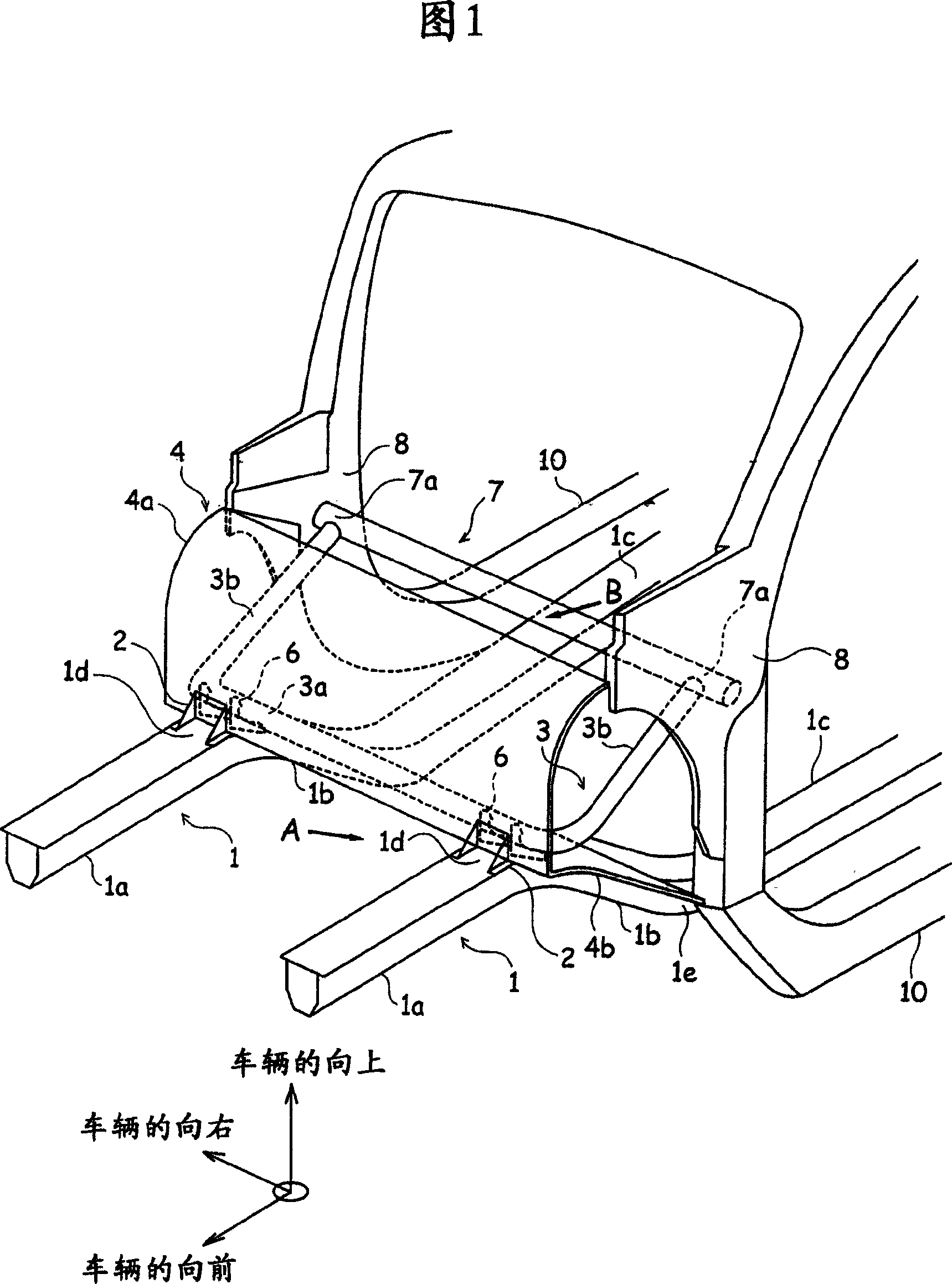

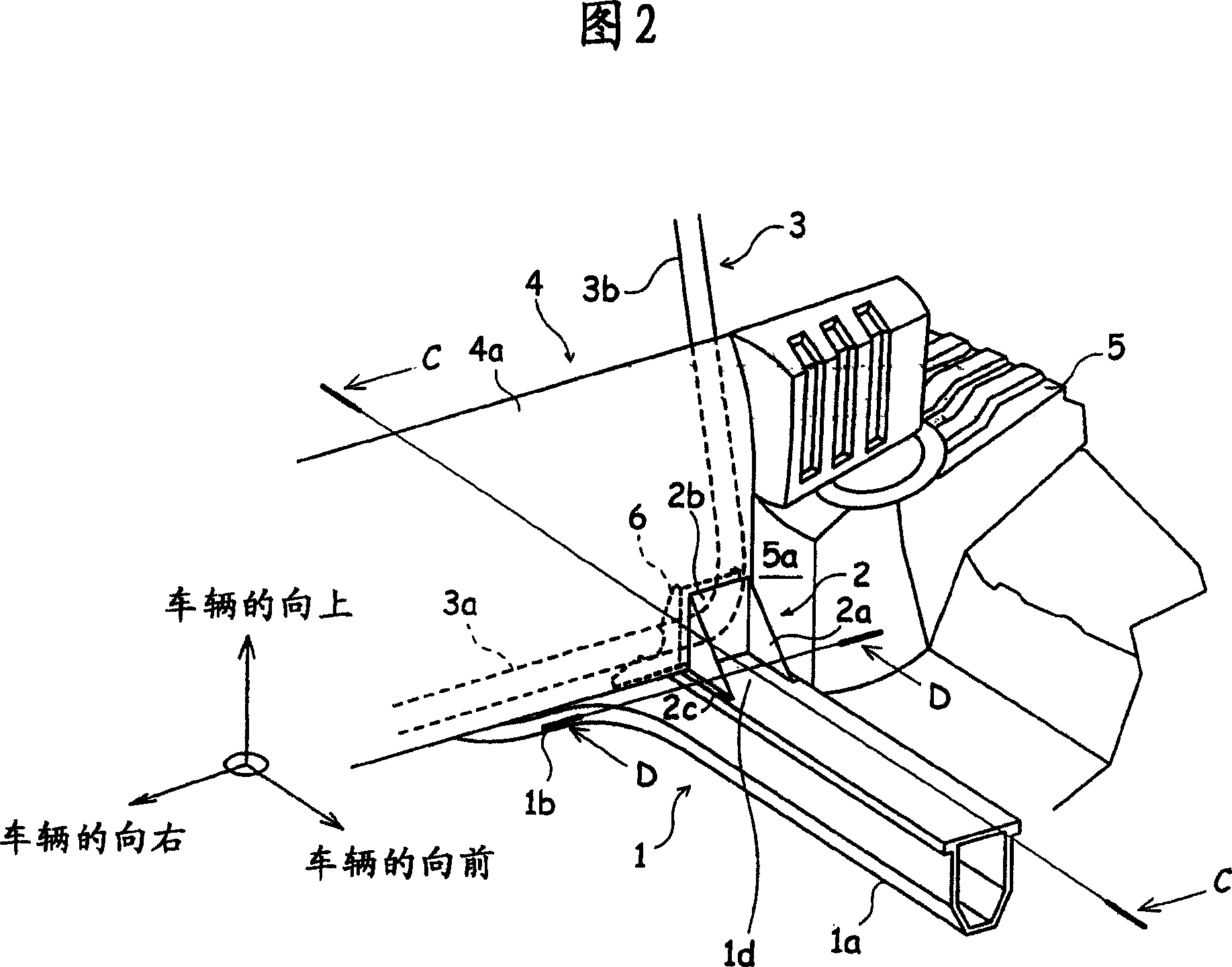

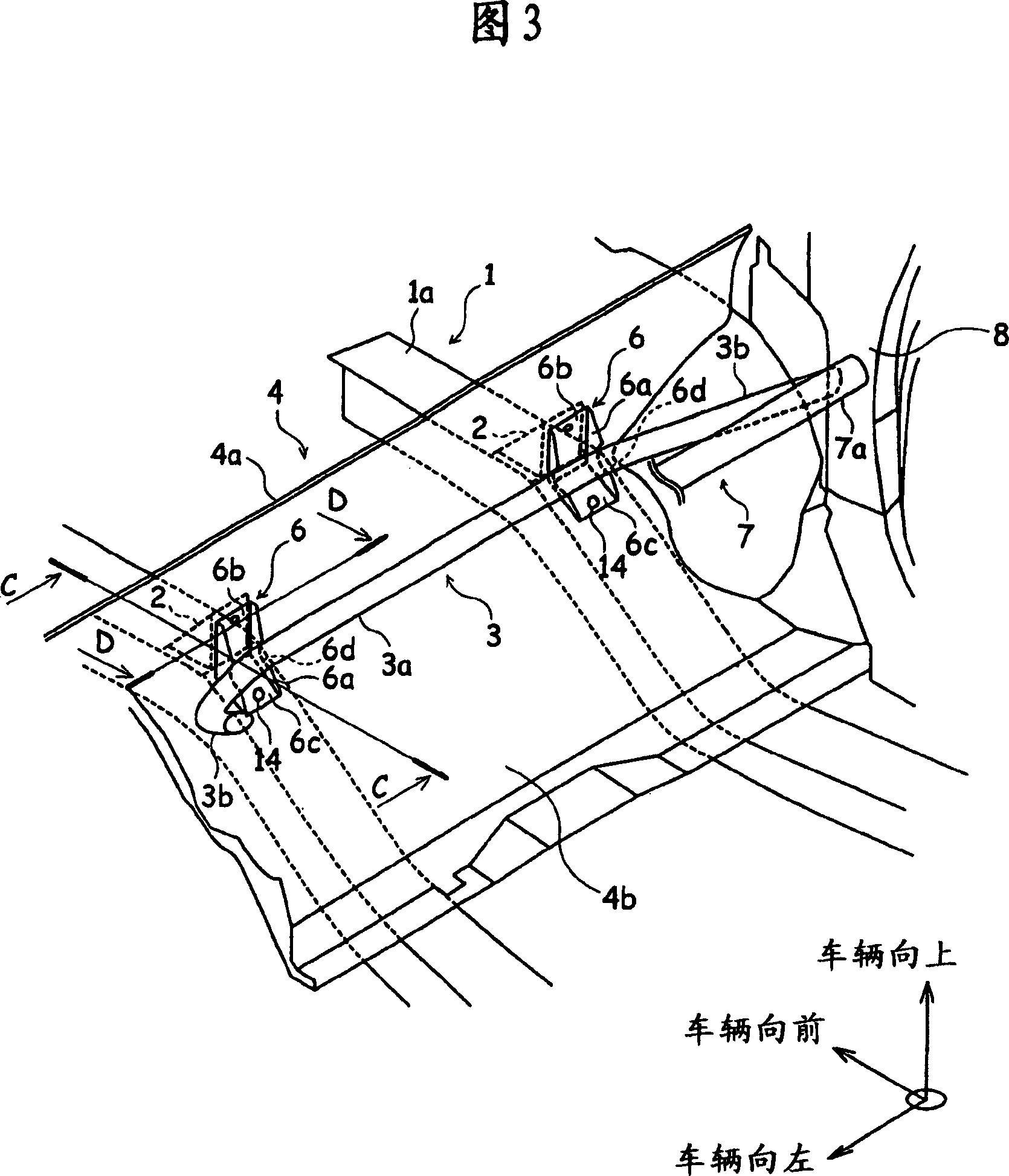

[0043] A preferred embodiment of the invention will now be described with reference to the accompanying drawings.

[0044] As shown in FIG. 1, a vehicle using the vehicle body structure of the present invention has a pair of front side members 1 and 1 extending in the lengthwise direction of the vehicle body. left side). Moreover, the vehicle also has a pair of side sills 10 and 10 extending in the lengthwise direction of the vehicle body. One is on the left side, along the width of the body. From the side sills 10 and 10 rise a pair of front pillars 8 and 8 extending upwardly to the roof of the vehicle. And, a deck beam 7 extending in the width direction of the vehicle body is provided between the two front pillars 8 and 8 so as to be connected therebetween, and the connecting portions 7a and 7a on the ends of the deck beam 7 are welded To front uprights 8 and 8.

[0045] A buffer beam 3 is placed between the connecting portions 7a and 7a on the ends of the front side mem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap