Gas-range

A gas stove and gas technology, applied in the field of gas stoves, can solve the problems of sealing gasket 113 wear, protection ring 100 rotation, and inability to determine the position of the trivet metal frame, etc., and achieve the effect of eliminating troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

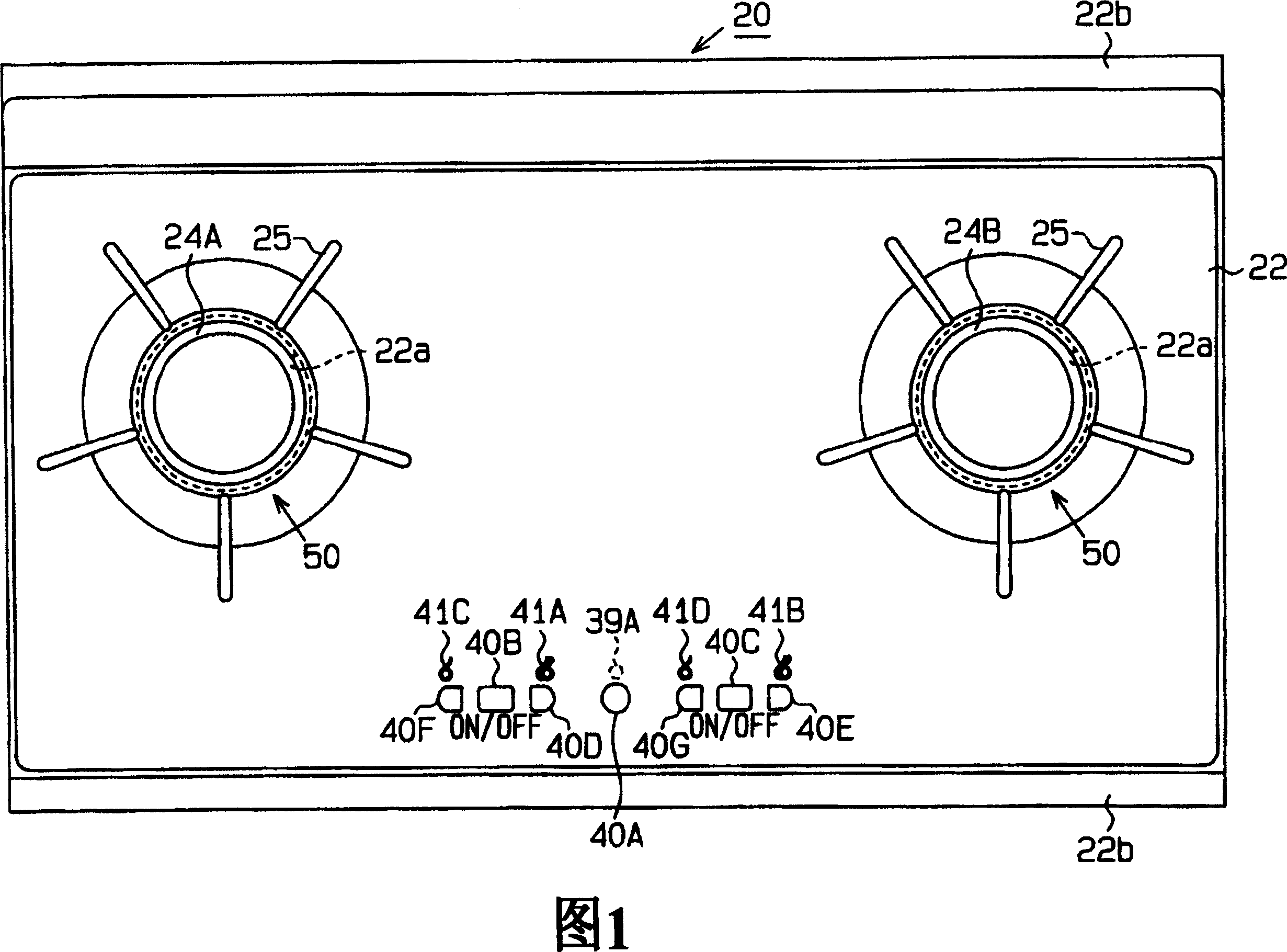

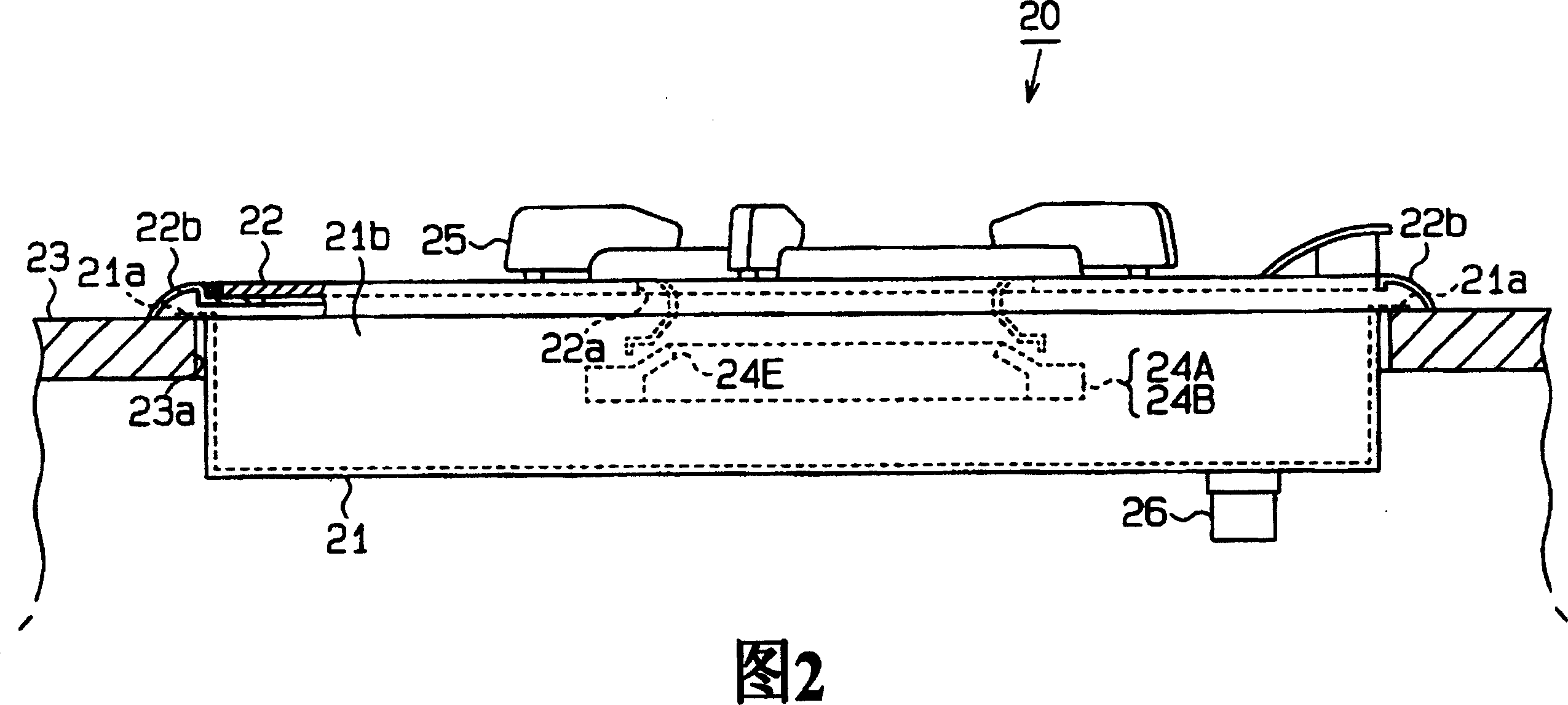

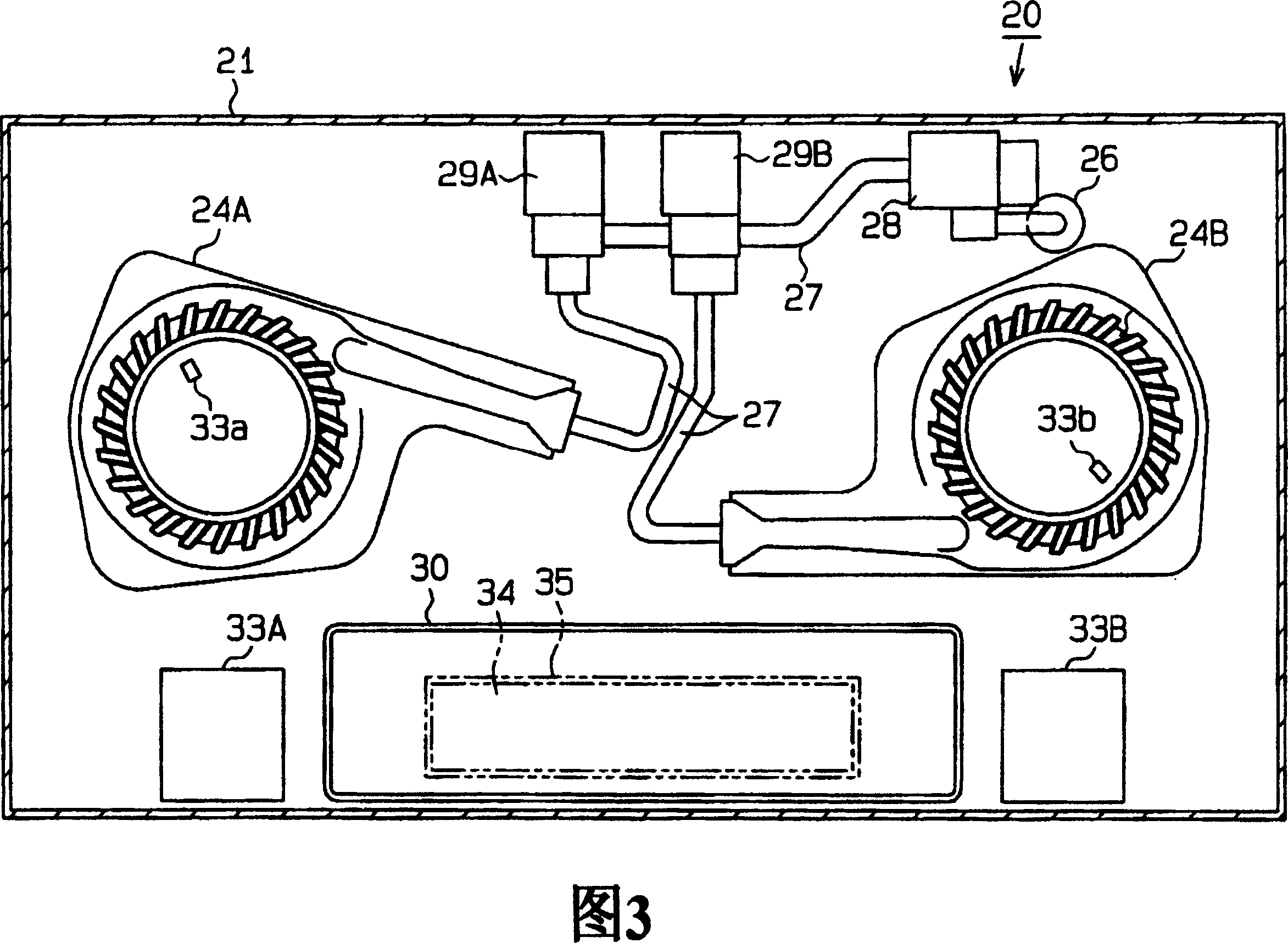

[0038] Next, a first embodiment of a gas range embodying the present invention will be described with reference to FIGS. 1 to 10 . In the drawings, "ON / OFF" means "on / off".

[0039] As shown in FIGS. 1 and 2 , the main body case 21 as the main body of the gas range 20 is a box-shaped body with an opening on the upper surface. A flange 21 a is formed on the outer edge of the upper end of the main body case 21 . The top opening 21b of the main body case 21 is covered by a glass cover 22 made of heat-resistant glass. At the rear of the glass cover 22, a pair of burner openings 22a are formed, and a cap-shaped The frame 22b. Although this glass cover plate 22 has translucency, it is colored (dark), so that people cannot see the situation in the main body box 21 clearly. And, the main body box 21 is inserted in the installation hole 23a formed on the stove top 23 of the kitchen, and the flange 21a of the main body box 21 is supported on the stove top 23, forming a so-called susp...

no. 2 Embodiment approach

[0061] Next, a second embodiment of a gas range embodying the present invention will be described with reference to FIG. 11 . In the second embodiment, on the basis of the first embodiment, the configurations of the lower ring and the mounting bracket are changed. In the following description, the same parts as those of the first embodiment are denoted by the same reference numerals and their descriptions are omitted.

[0062] As shown in FIG. 11( a ), on the extended portion 67 of the lower ring 66 is formed a protrusion 68 extending in the direction of its extension. The protrusion 68 functions as a structure for increasing the strength of the extension 67, and when the guard ring 50 is attached to the burner opening 22a, the extension 67 is prevented from sagging due to its own weight.

[0063] And as shown in Fig. 11 (b), (c), a concave portion 35a is formed at the rear corner of the mounting frame 35, and the engaging portion 64 is engaged with the concave portion 35a to...

no. 3 Embodiment approach

[0067] Next, a third embodiment of a gas range embodying the present invention will be described with reference to FIG. 12 . In the third embodiment, the configuration of the lower ring is changed on the basis of the first embodiment.

[0068] On the outer edge of the lower flange 57 of the lower ring 71 are formed two extensions 72A, 72B extending in the radial direction thereof, and the ends of the two extensions 72A, 72B form a buckling portion 73 . The extension 72A and the extension 72B are parallel to each other. And between the end of the extension 72A and the end of the extension 72B, the snap-fit is made in a slightly wider state (state shown by a solid line in FIG. The extensions 72A, 72B can be snapped onto the mounting frame 35 by pinching the rear corners of the mounting frame 35 by the portion 73 .

[0069] This embodiment has the following effects in addition to the same effects as (1) to (4) of the first embodiment.

[0070] (6) The extensions 72A, 72B pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com