Floating bearing

A floating bearing and bearing technology, which is applied to bearings, linear motion bearings, shafts and bearings, etc., can solve the problems of high assembly cost, complicated assembly work, and large assembly labor intensity, so as to achieve low cost and low incidental cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

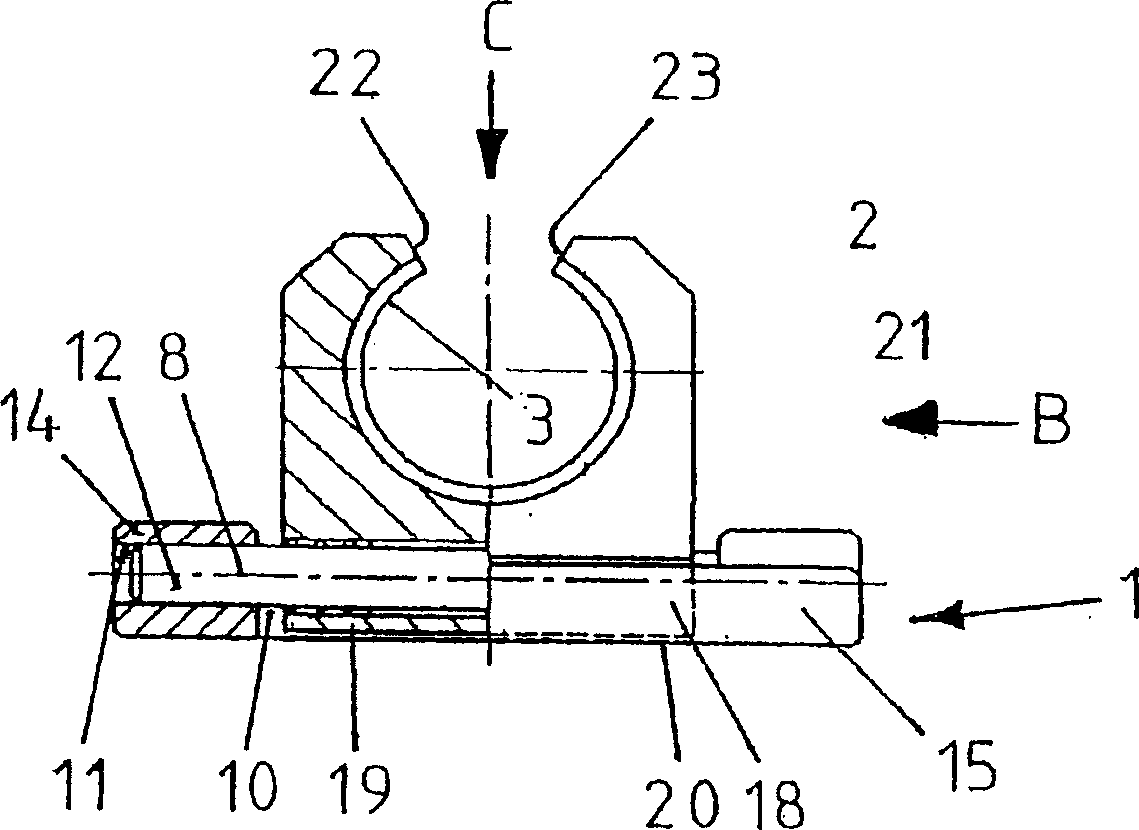

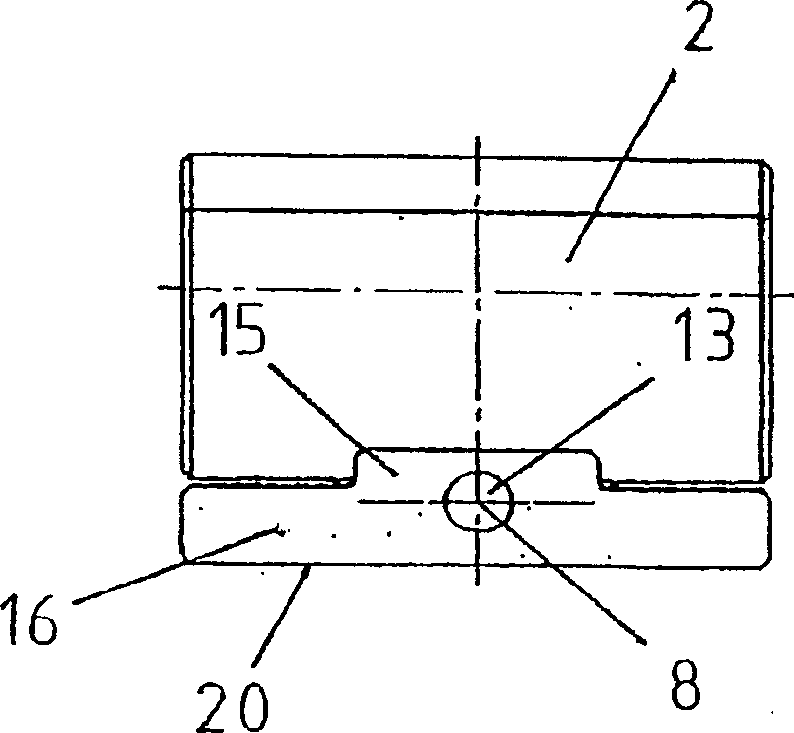

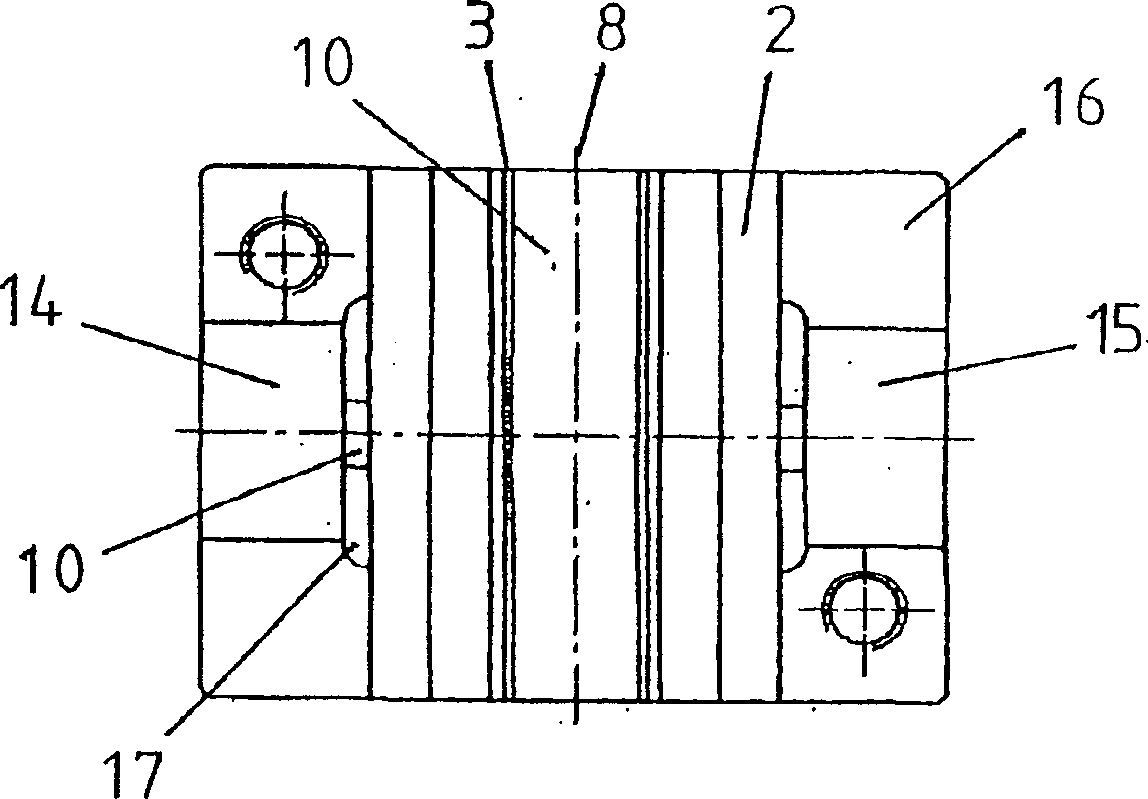

[0040] Such as Figure 1b-3c As shown in the three embodiments, the non-locating bearing has a bearing box 2, which is connected to the slider through a connecting device 1 (see Figures 4a-4c ) connection, and accommodate the linear bearing 3.

[0041] As detailed below, the connection device 1 is designed such that the bearing housing 2 is perpendicular to the corresponding axis (see Figure 4b The longitudinal direction of the reference number 4) and parallel to the axis of the shaft 4 (see Figures 4a-4c The axis plane defined by reference numerals 5 and 6 in (see Figure 4a The reference numeral 7) in can be set movably.

[0042] The connection device 1 is also designed such that the bearing housing 2 is arranged rotatably about an axis 8 extending perpendicularly to the longitudinal direction of the shaft 4 and parallel to the shaft plane 7 .

[0043] In order to be relative to the slider (see Figures 4a-4c Reference numeral 9) in the linear guidance and rotation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com