Separation device of storehouse type powdered coal boiler powder making system powder sending air laeking

A technology of pulverized coal boiler and separation device, which is applied in the directions of block/powder supply/distribution, combustion using block fuel and powder fuel, combustion method, etc., can solve problems such as high cost and difficult separation, and achieve simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

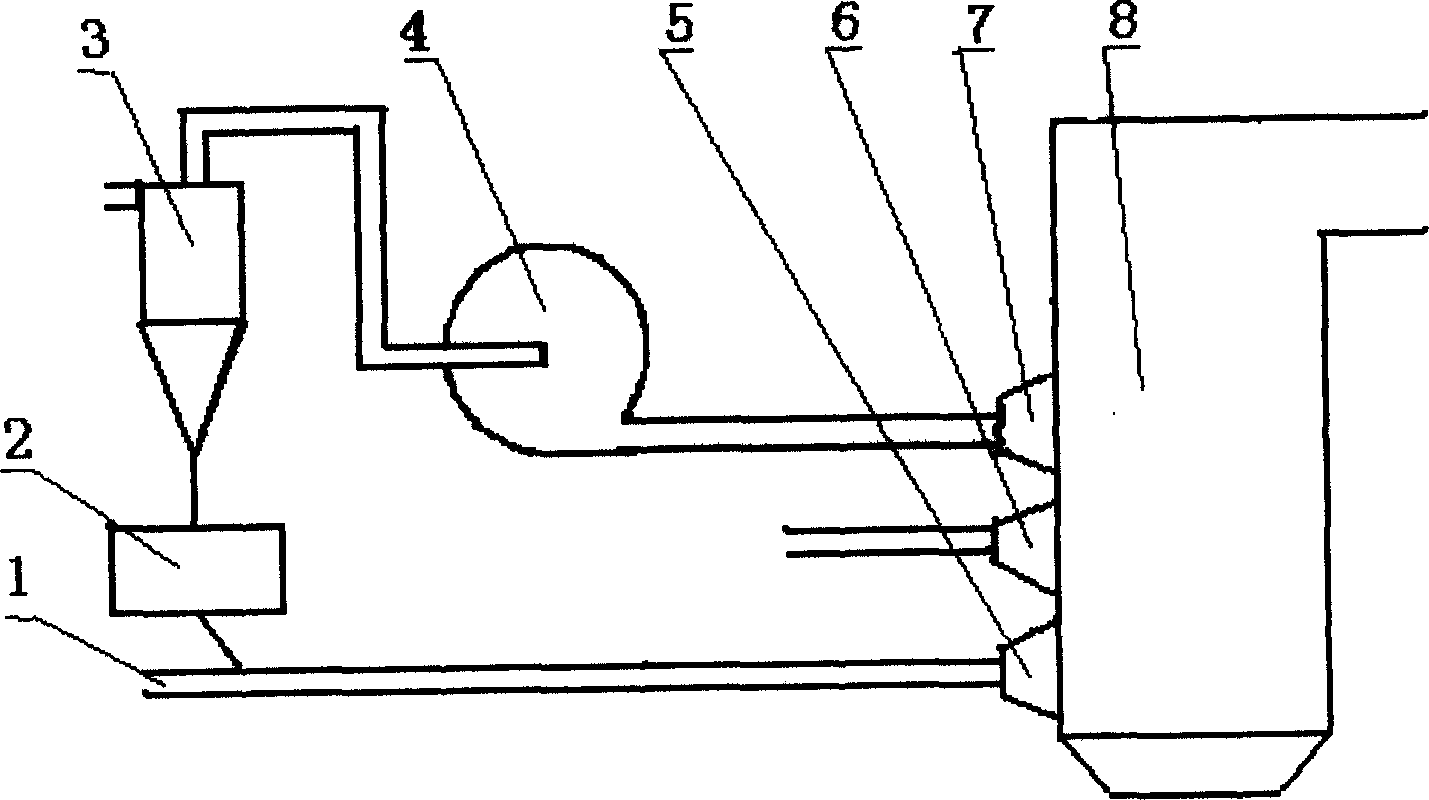

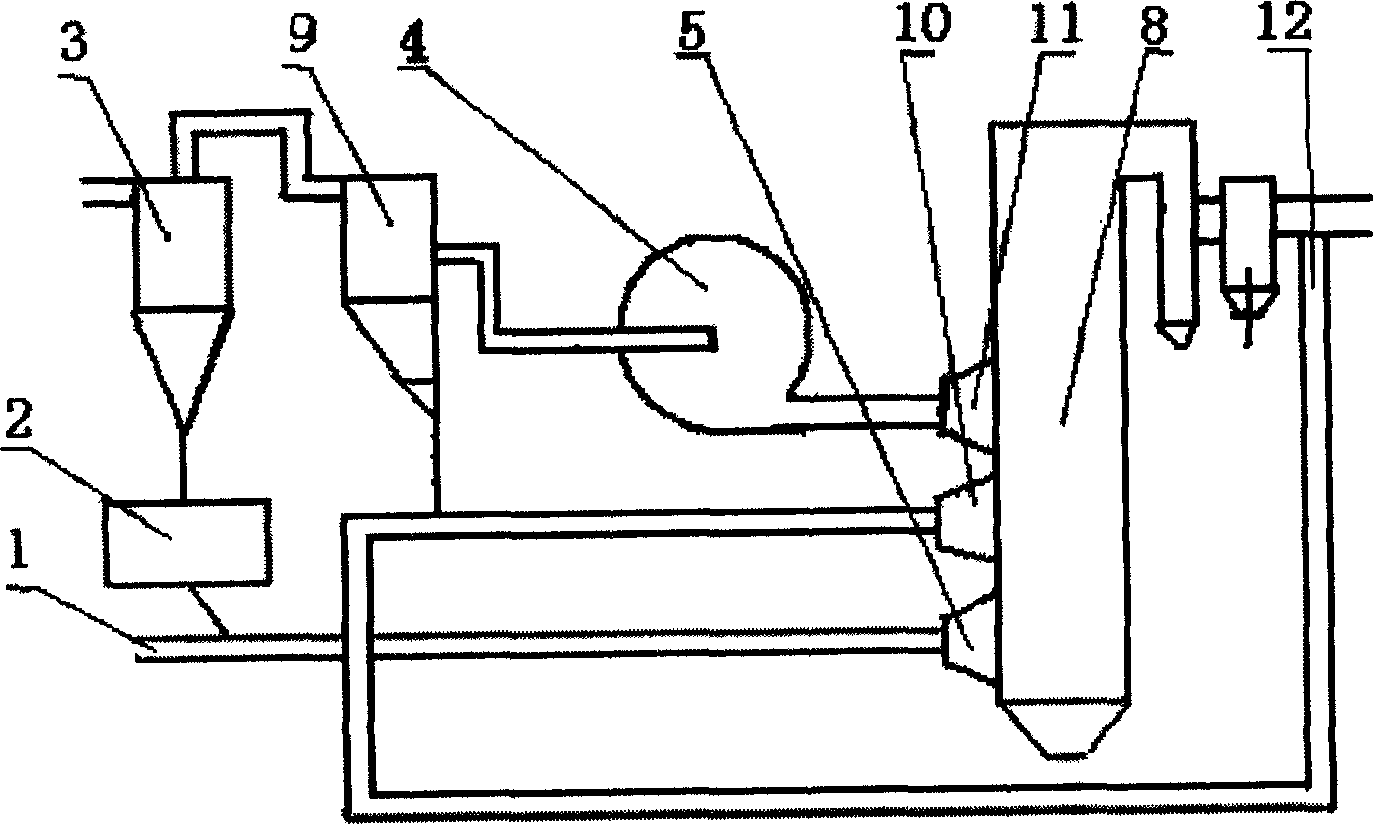

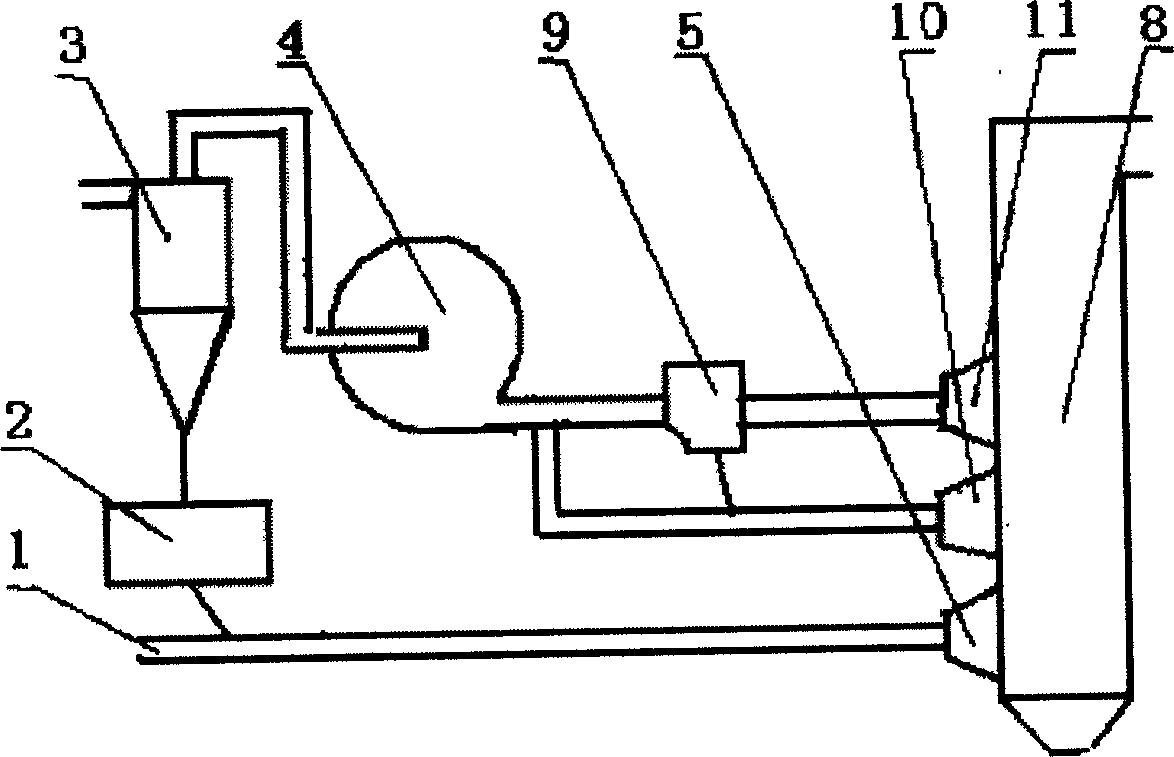

[0012] Figure 4 Schematic diagram of the structure of the separation device for powder feeding and exhaust gas in the pulverization system of the storage type pulverized coal boiler provided by the present invention. It includes a fine powder separator 3, a powder discharge fan 4 connected with the gas outlet of the fine powder separator, a coal powder bin 2 arranged at the lower part of the fine powder separator, and a primary air duct 1 connected with the coal powder bin. When the pulverized coal contained in the exhaust gas from the fine powder separator 3 flows through the impeller of the powder exhaust fan 4 rotating at high speed, due to the centrifugal force, the concentration distribution of the airflow containing pulverized coal at the outlet of the fan is no longer uniform , Separation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap