A decanter centrifuge

A centrifuge, sedimentation technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of reduced area, poor process economy, poor dehydration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

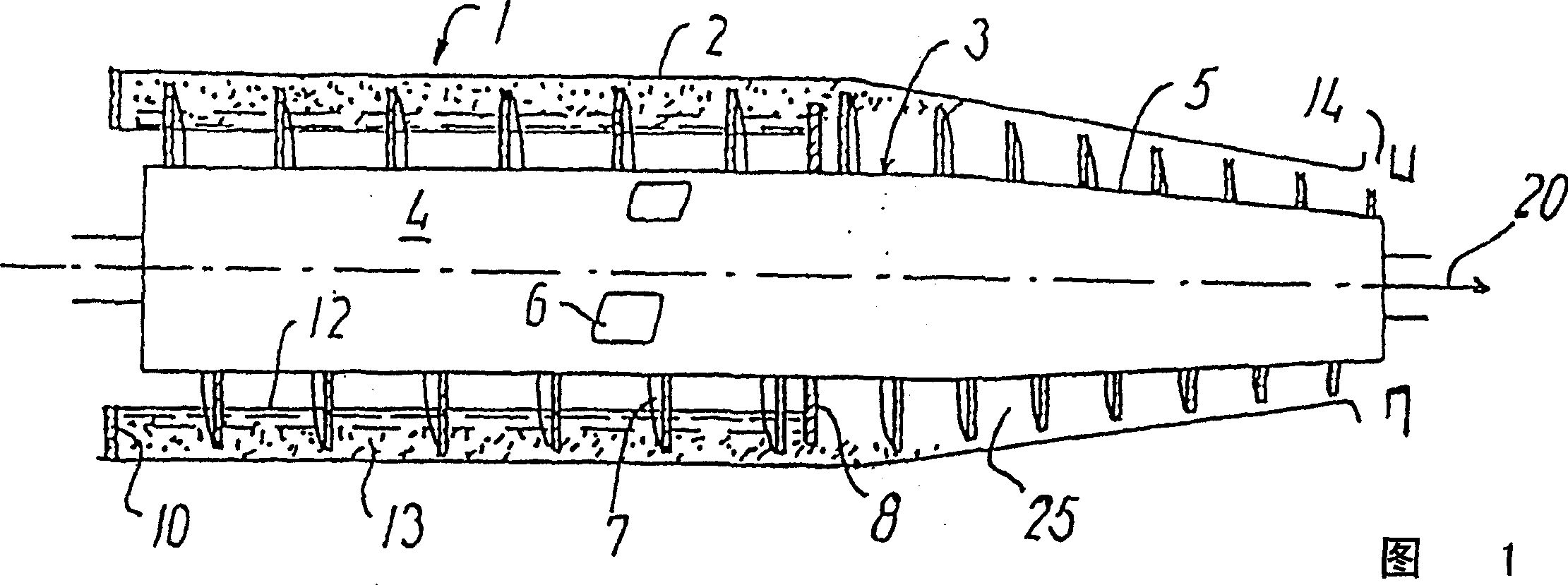

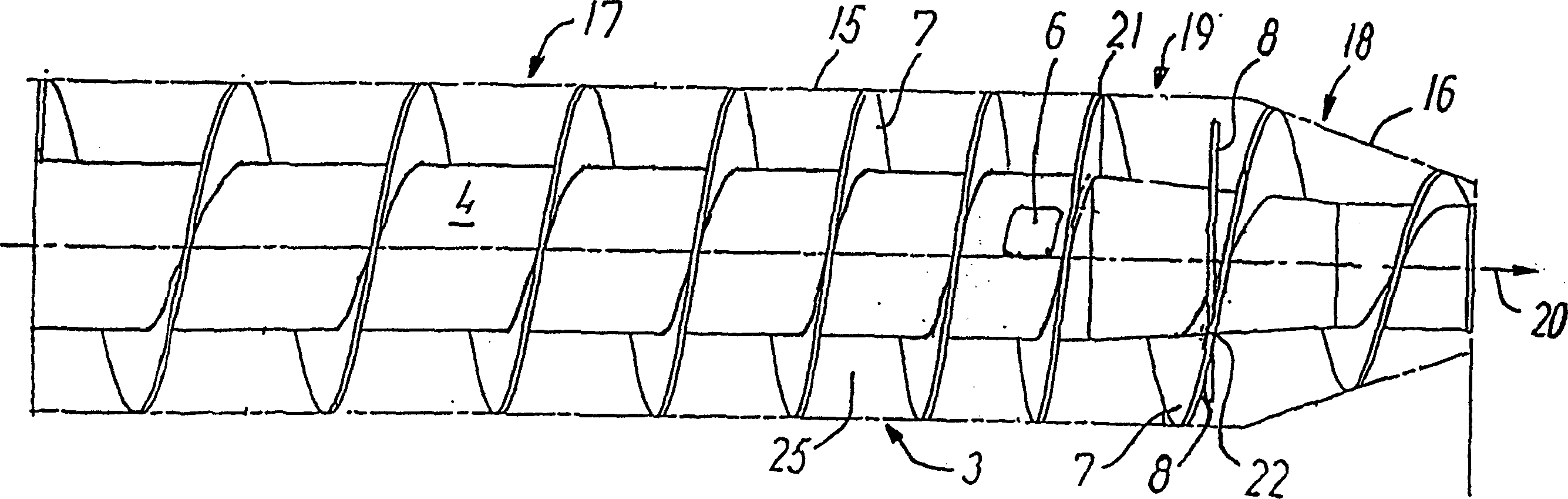

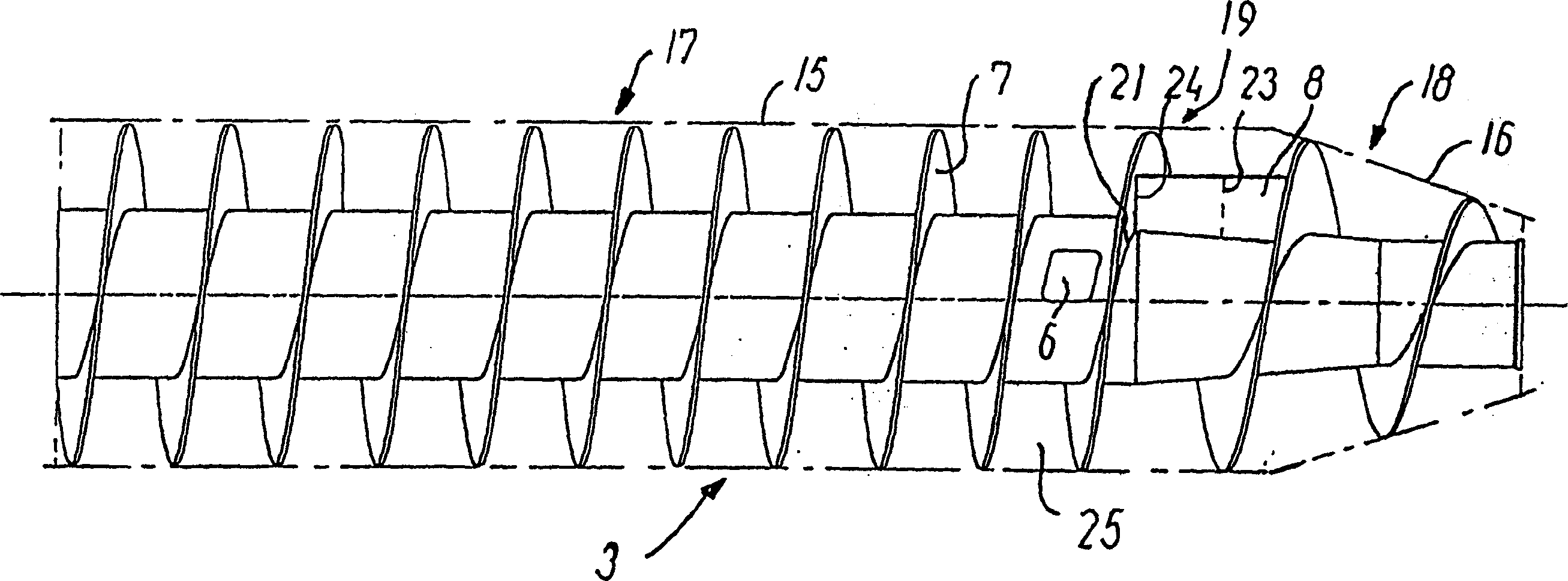

[0024] The decanter centrifuge 1 among Fig. 1 has the hollow drum 2 with separation chamber, and screw conveyor 3 is arranged in the separation chamber, and it has the main body 4 with screw rod, and screw rod has helical sheet 7 to wind several turns. The main body 4 is substantially cylindrical and has a conical portion 5 at one end thereof. An inlet opening 6 for the material to be separated is provided in the screw conveyor 3 and a discharge opening 14 for the separated heavy phase is provided in the drum 2 . The light phase 12 is positioned closest to the body 4 of the auger, while the heavy phase 13 is positioned inside the drum 2 , as represented in the figures. The light phase is removed via the discharge side 10 on the drum. The heavy phase is conveyed by the turns of the screw to a discharge opening 14 in the conical end of the bowl. The figure shows that the baffle 8 is an annular disc, perpendicular to the longitudinal or axial axis of the screw conveyor.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com