Boiler manhole cover manufacturing equipment and manufacturing method

A manhole cover and boiler technology, applied in milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve the problems of single method, inability to process workpieces, and a lot of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

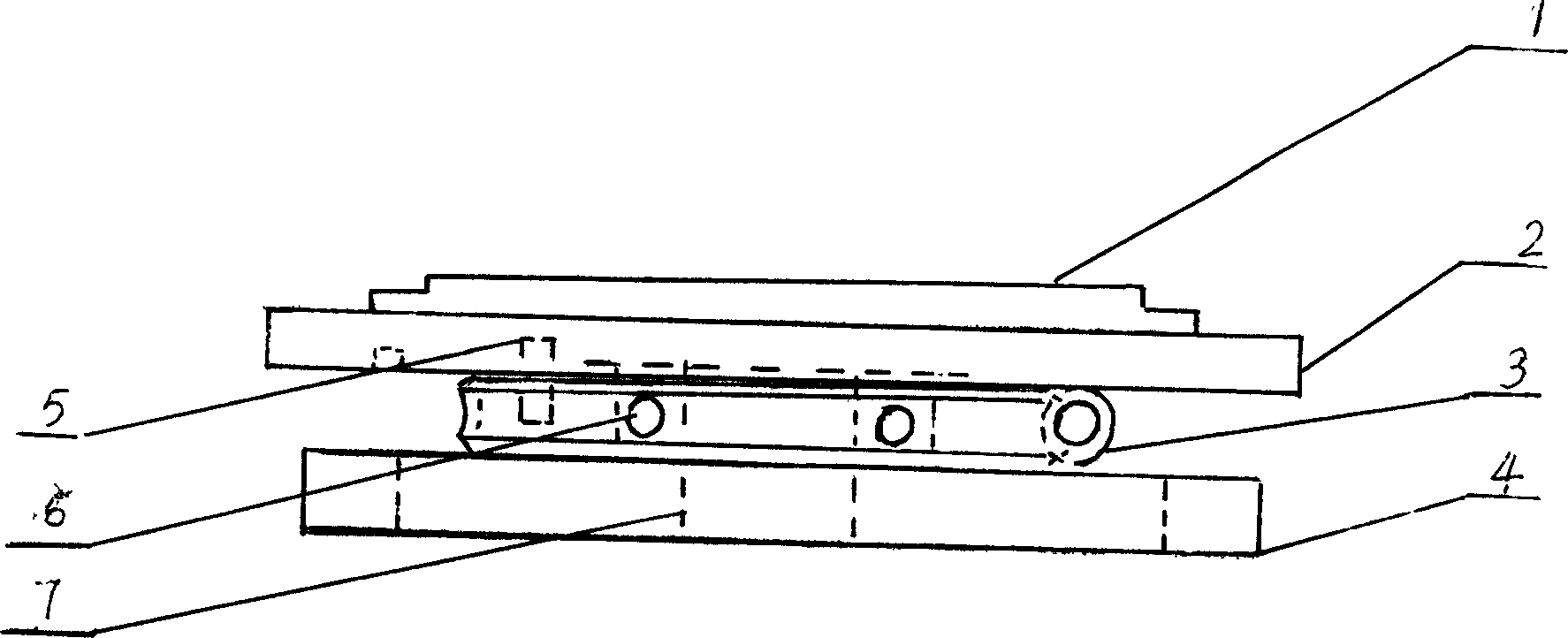

[0010] Boiler manhole cover production equipment includes a chassis 4, on which a fixed shaft 7 is arranged, and a worm gear pair 3 connected with the fixed shaft 7 is provided at the same time, and two sliders are arranged on the top of the fixed shaft 7, and the worm wheel A lever device 5 is arranged on the pair 3, a processing table 2 is arranged on the upper end of the fixed shaft 7, and a lever groove is arranged at the bottom of the processing table 2, and the lever device 5 is connected with the processing table through the lever groove. 2 is provided with a cross-shaped groove that runs through the upper and lower tables, and the slider is embedded in the cross-shaped groove. In addition, there are workpiece fixing holes and 6 bearings on the processing table. When in use, the workpiece 1 can be fastened on the work table. superior.

[0011] Boiler manhole cover manufacturing equipment The method for manufacturing boiler manhole covers includes the following steps: (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com