Folding-type grain pile pedal

A folding, pedal technology, applied in roads, special pavements, roads, etc., can solve problems such as slipping and pedals are difficult to move, and achieve the effect of easy use, convenient movement and storage, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

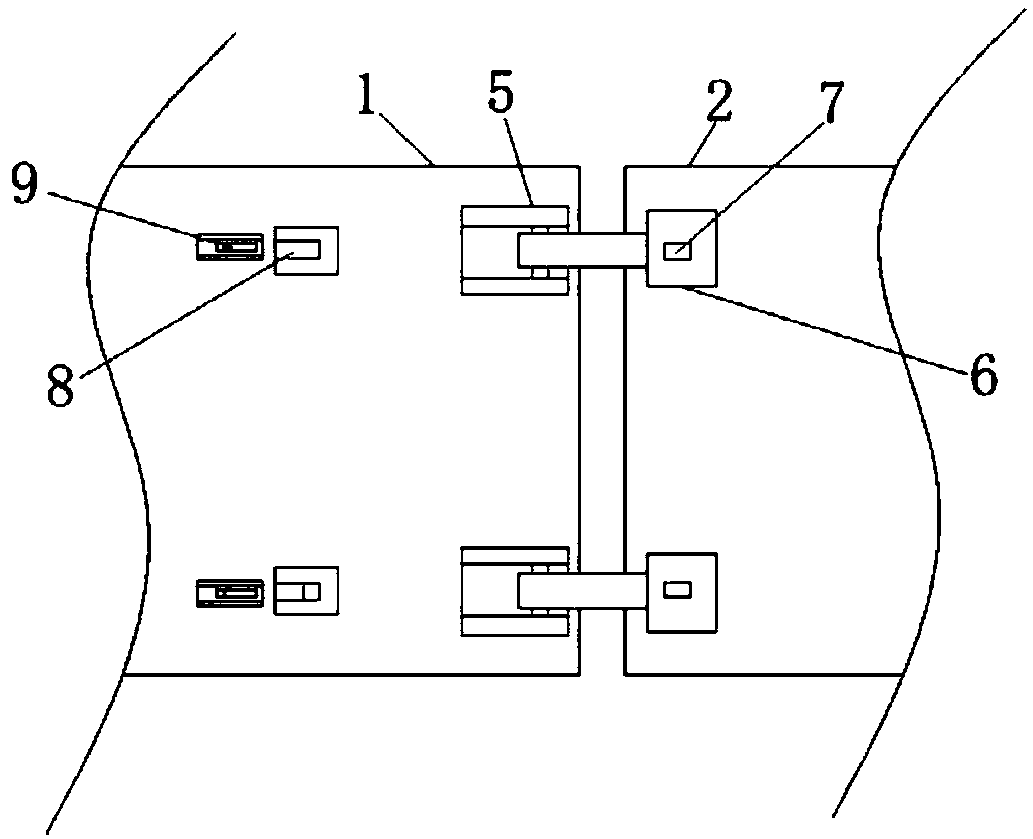

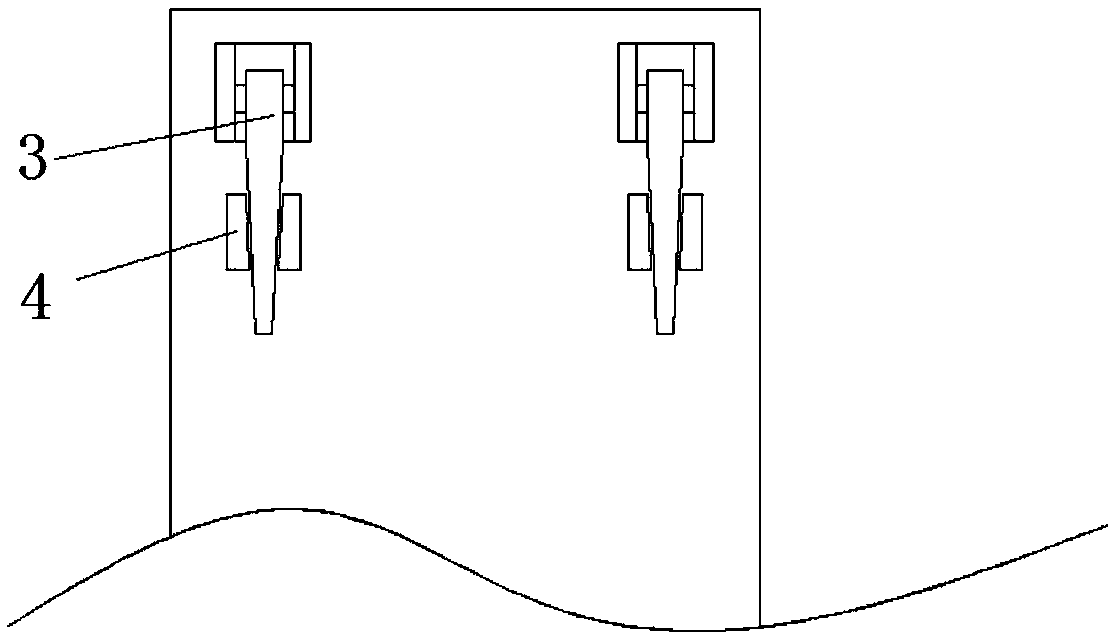

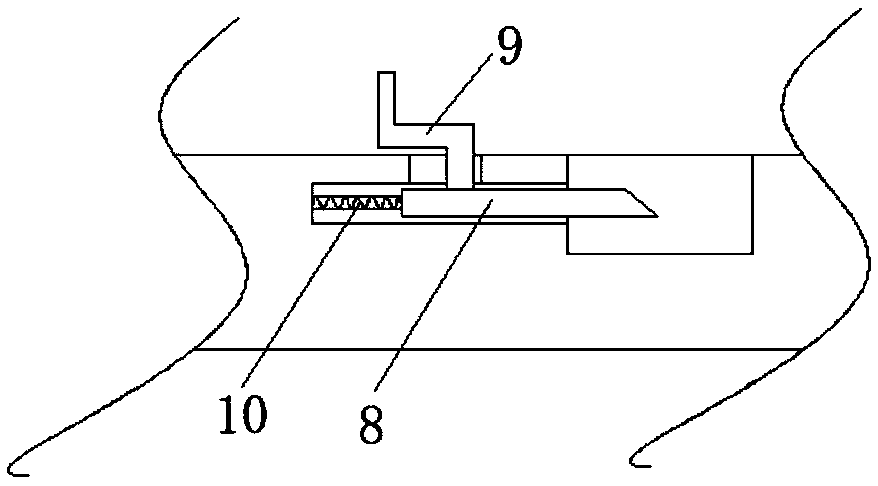

[0029] refer to Figure 1-5 , a foldable grain pile pedal, used on the grain pile to facilitate managers to walk on the grain pile, the pedal includes a first pedal 1 and a second pedal 2, the length and width of the first pedal 1 and the second pedal 2 are the same The bottom ends of the first pedal 1 and the second pedal 2 are all rotatably equipped with a rotating rod 3, and the bottom ends of the first pedal 1 and the second pedal 2 are all fixed with a rotating seat 13 (combined with Figure 6 and Figure 7 ), the rotating rod 3 passes through the rotating shaft 14 (combined with Figure 6 and Figure 7 ) is rotatably connected with the rotating seat 13, one side of the rotating rod 3 is provided with a block 4, and the block 4 is fixedly connected with the bottom ends of the first pedal 1 and the second pedal 2, and the bottom end of the block 4 is provided with a first Draw-in slot, rotating rod 3 is positioned in the first draw-in groove, and the bottom end of rotat...

Embodiment 2

[0032] The difference from Example 1 is that the combination Figure 6 and Figure 7 As shown, in this embodiment, an elastic block 15 is fixedly connected to the top of the rotating rod 3, such as sticking, the elastic block 15 is elastic and can be deformed. When the elastic block 15 is in a non-compressed state, the longitudinal length of the elastic block 15 is greater than that of the rotating rod. 3 The distance between the top end and the bottom end of the first pedal 1, the longitudinal length of the elastic block 15 is greater than the distance between the top end of the rotating rod 3 and the bottom end of the second pedal 2, so that the rotating rod 3 is rotated so that the rotating rod 3 and the first pedal 1 is perpendicular to the second pedal 2, and the elastic block 15 is deformed and compressed, so that the rotating rod 3 is in contact with the first pedal 1 and the second pedal 2. During use, the rotating rod 3 is not easy to rotate in position, ensuring safe...

Embodiment 3

[0035] The difference from Example 2 is that the combination Figure 8 and Figure 9 As shown, the first pedal 1 and the second pedal 2 of this embodiment are all provided with a first receiving groove 16 with the opening facing upwards, and the opening of the first receiving groove 16 is provided with a first sealing cover 26, and the first sealing cover 26 is threaded. Connected to the first receiving groove 16, and the top of the first sealing cover 26 is flush with the tops of the first pedal 1 and the second pedal 2, the bottom of the first receiving groove 16 is provided with a first opening, and the first receiving groove 16 A first spring 17 and a first limiting post 18 are provided inside, and the first spring 17 and the first limiting post 18 are arranged sequentially from top to bottom. The top of the first limiting post 18 is provided with a first limiting shoulder 19, One end of the first spring 17 abuts against the first sealing cover 26, the other end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com