Optical disc loading device and method

A technology for loading devices and optical discs, which is applied in the direction of recording information storage, instruments, etc., can solve the problems of increased manufacturing costs and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the disc loading device and method of the present invention will be described in detail below with reference to the accompanying drawings.

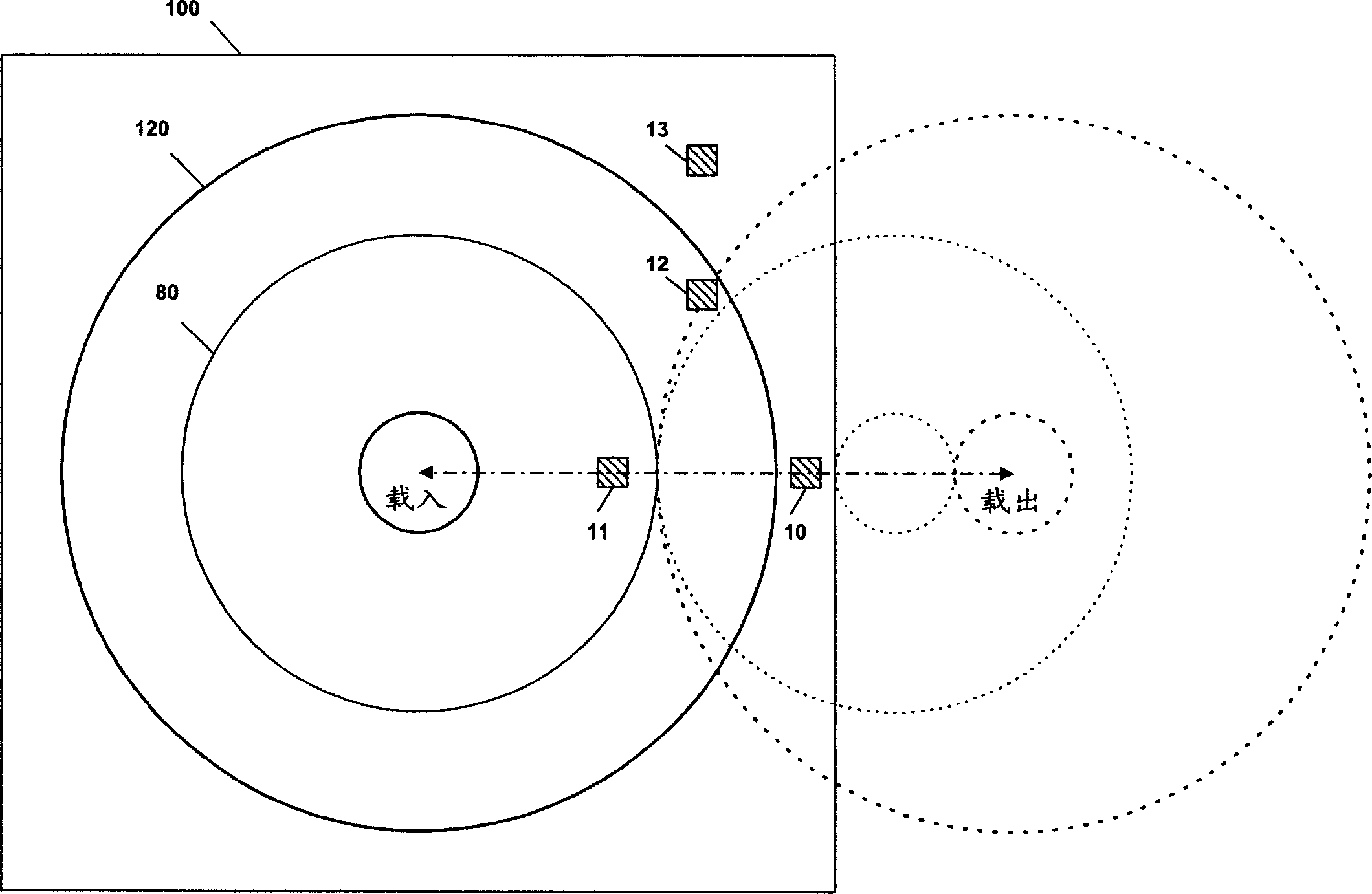

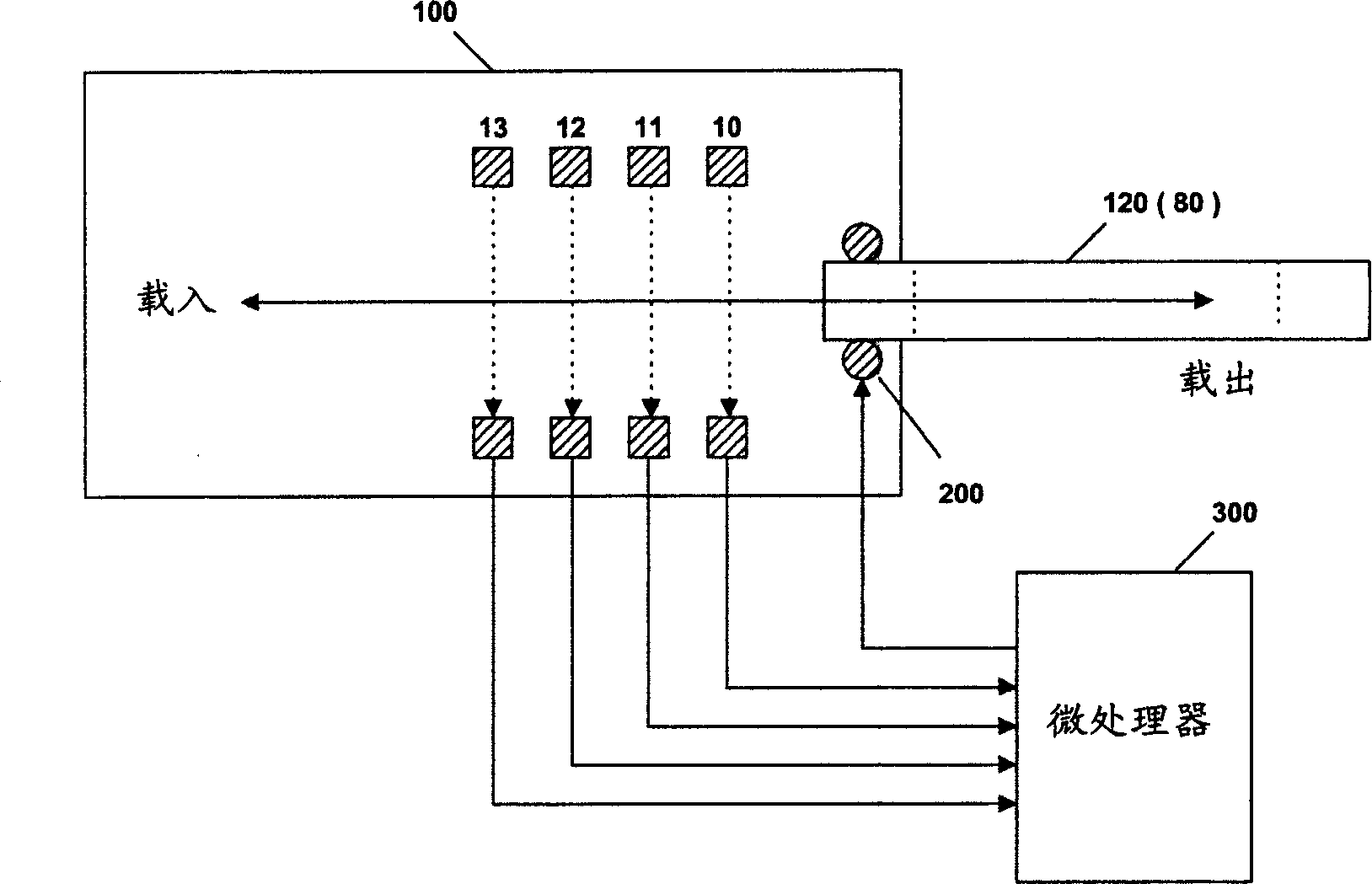

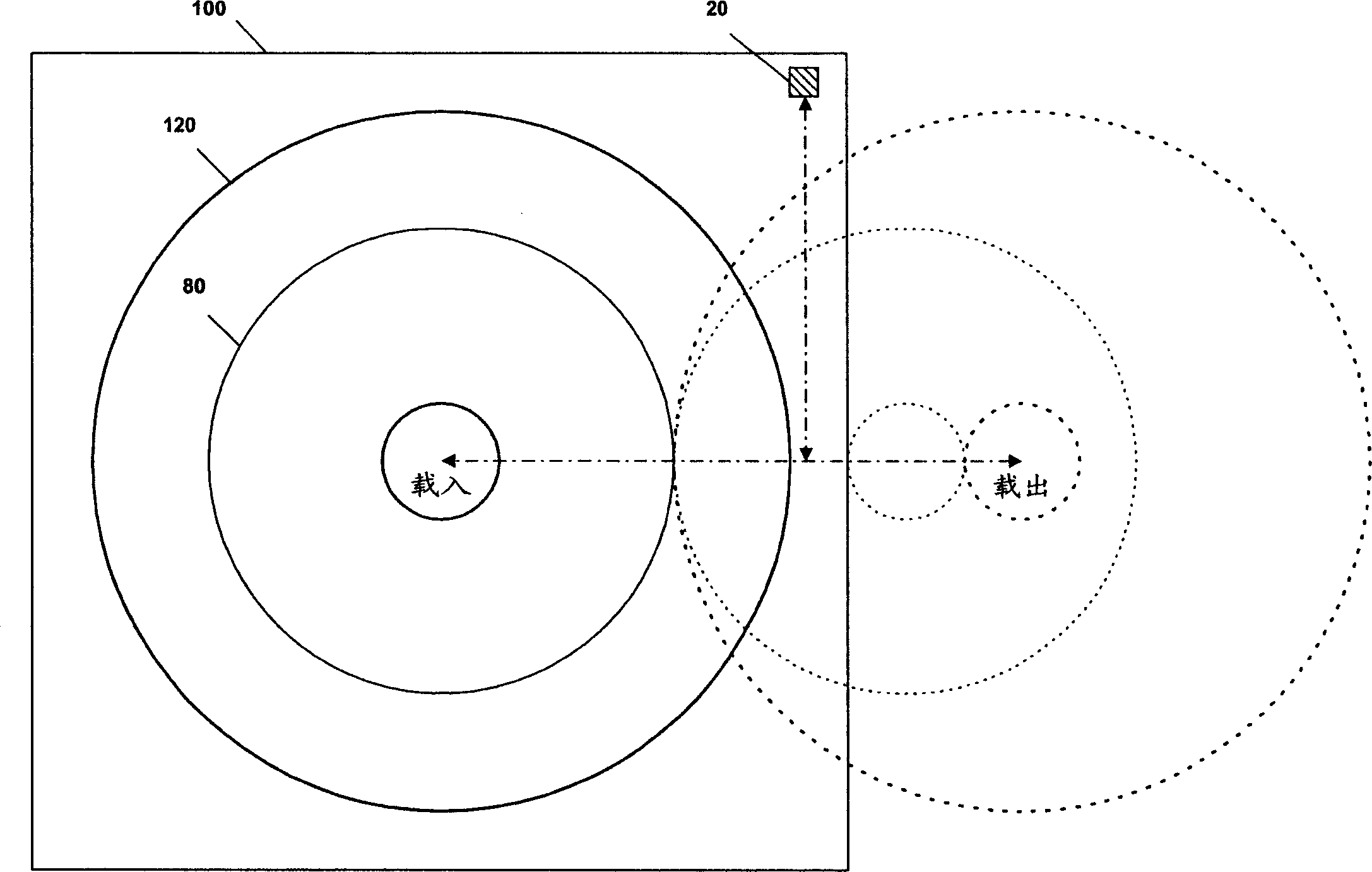

[0031] image 3 and Figure 4 It is a partial structural diagram of the disc loading device of the present invention.

[0032] The above optical disk loading device, as mentioned above, is a kind of optical disk loading for selectively loading or loading optical disks with different diameters into or out of the device by means of groove loading, including for selectively loading disks with a diameter of 120mm, for example The groove of any one of the disc compartment 100 in the disc 120 with a diameter of 80 mm and the disc 80 with a diameter of 80 mm. At the same time, the disc mounted on the above groove, such as image 3 As shown, the loading motor 200 is driven to load the outside or load the inside. At this time, in order to be able to detect the size and moving state of the optical disc installed in the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com