Device and method for diagnosing coke oven carbonizing chamber

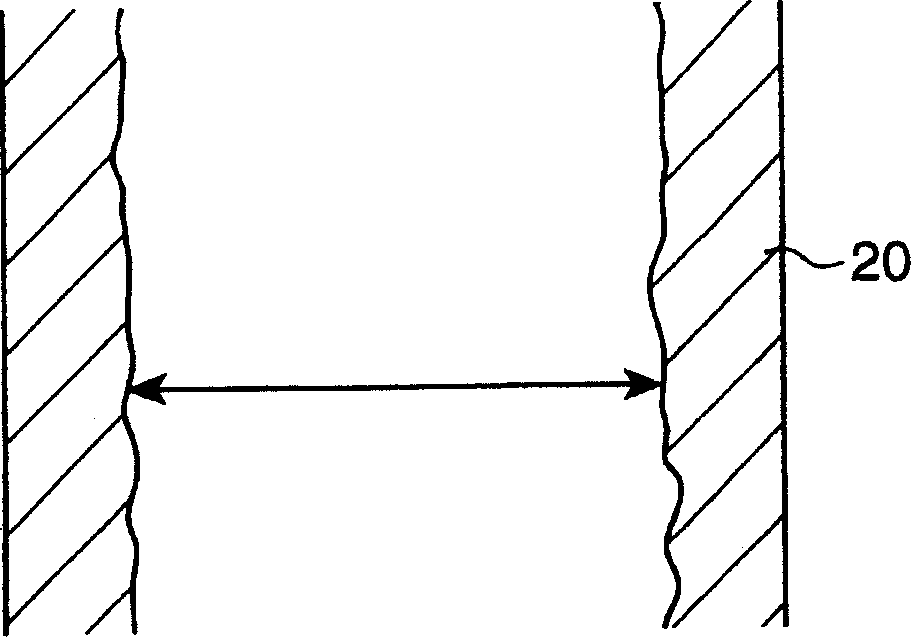

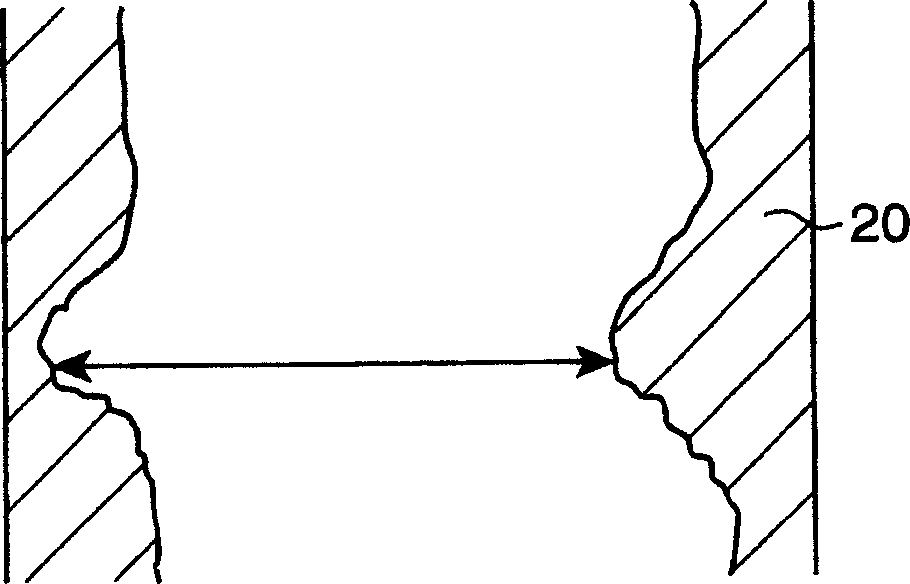

A technology of a diagnostic device and a diagnostic method, which is applied to the safety device of a furnace, a coke oven, a furnace control device, etc., can solve the problems such as the inability of the ejector to move and the problem of accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] Below, the present invention is given a more specific description through the examples; however, the present invention is not limited to the examples to be described below, and changes and implementation methods that do not depart from the scope of the gist of the present invention are all included within the scope of the present invention .

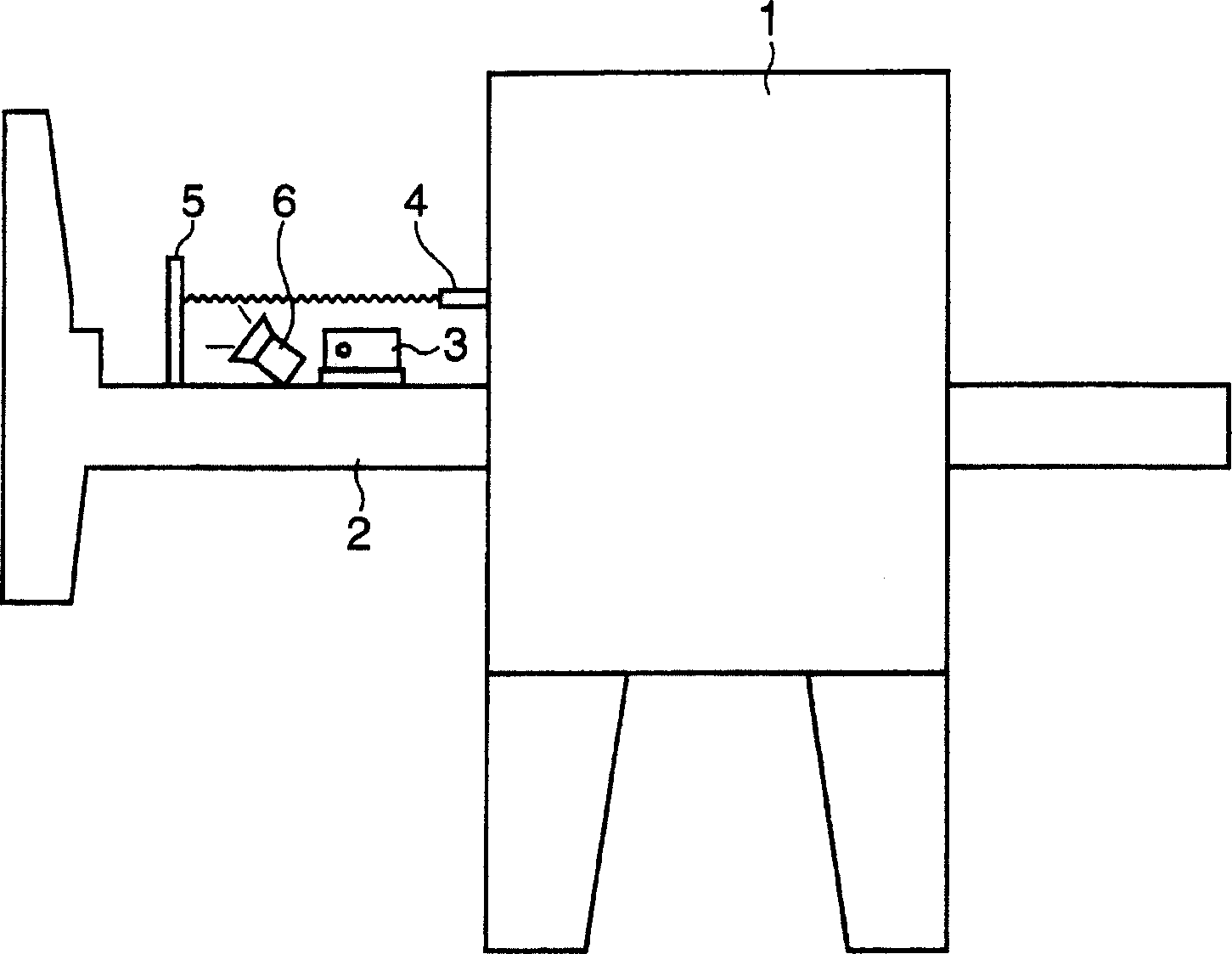

[0110] (1) The structure of the diagnostic device in the carbonization chamber of the coke oven

[0111] Such as Figure 4 As shown, a laser output unit 4 is set on the coke pusher body 1, and an internal observation device 3 and a steel plate with a checkerboard grid scale as a laser light receiving unit 5 are set on the ejector 2. The internal observation device 3 employed, such as Figure 5 As shown, it includes a laser range finder 11 , a camera as a laser light receiving position identification unit 6 , a programmable computer as a measurement data processing unit 12 , a power supply unit 13 , a camera as an imaging unit 14...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap